Multiple-stage copy milling machine

A profiling grinding, multi-station technology, used in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., which can solve the problem of workpiece clamping, unloading, inconsistency in processing, low processing efficiency, etc. problems, to ensure the quality of processing, reasonable structural design, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

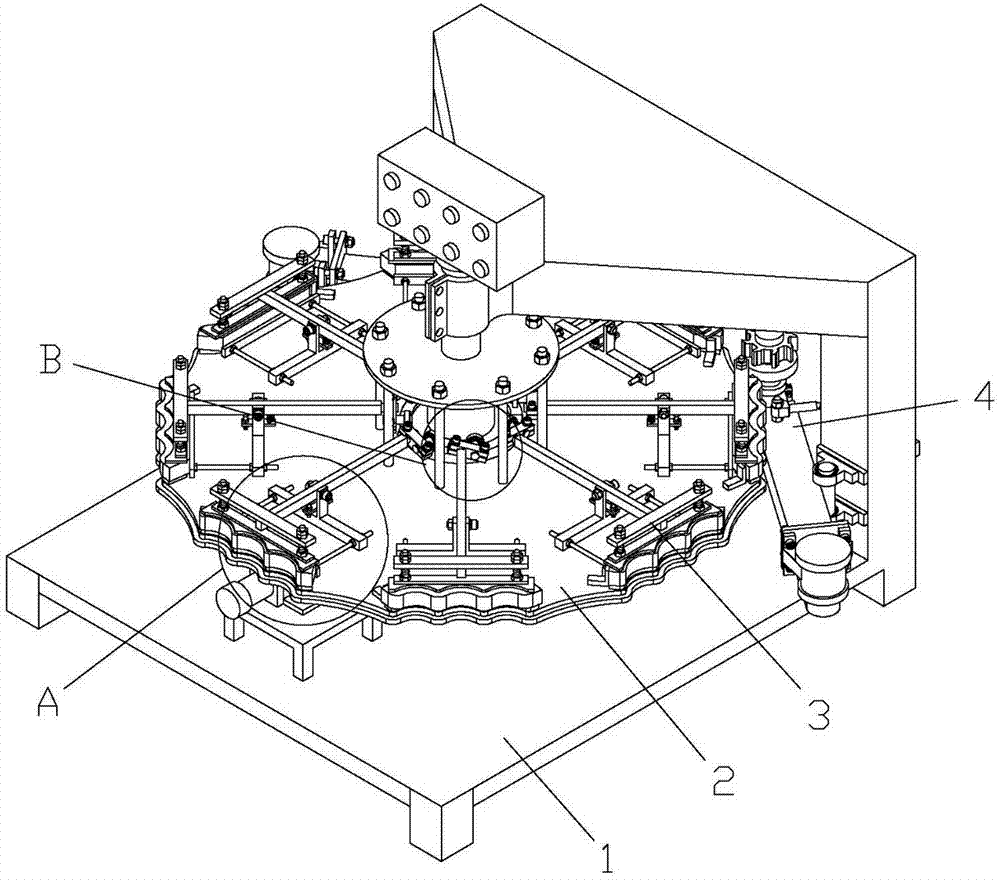

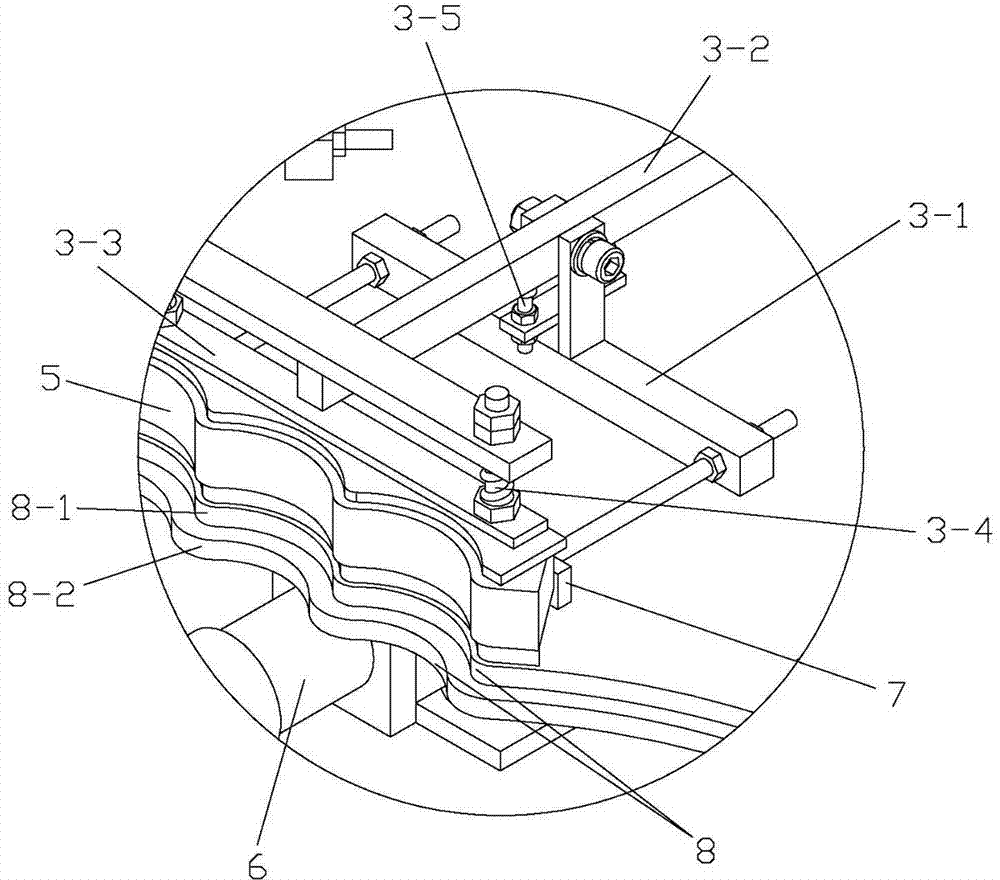

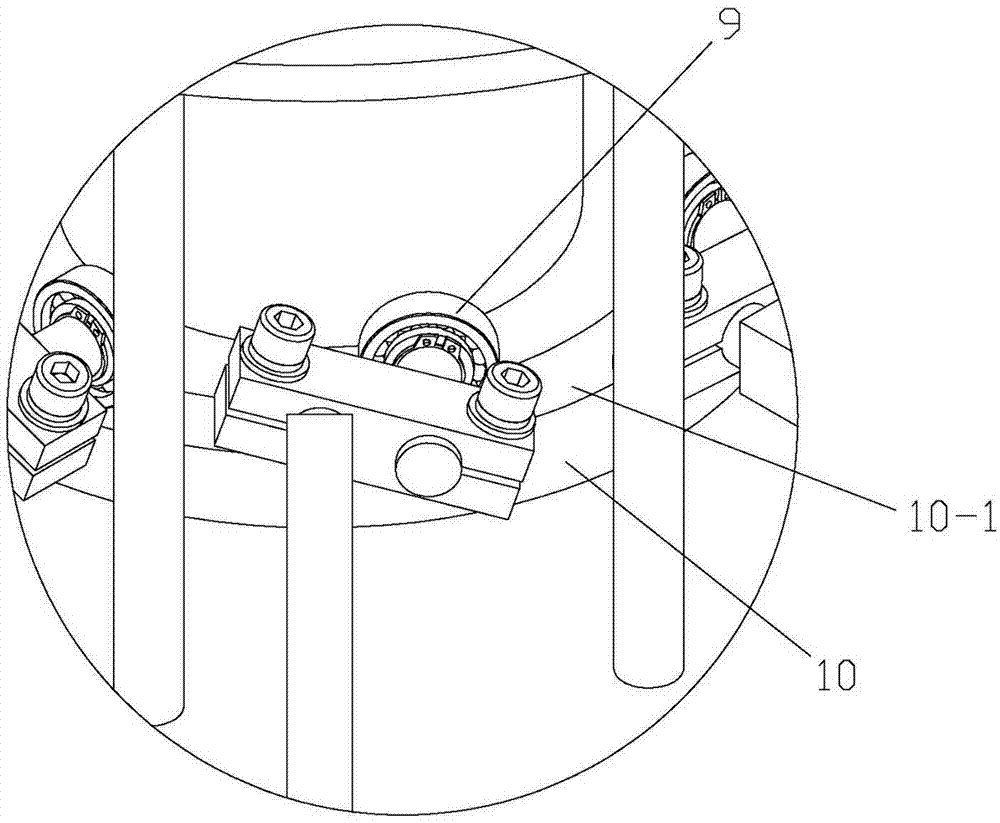

[0019] Referring to the accompanying drawings: this multi-station profiling grinding machine includes a base 1 on which a motor-6 drives a profiling turntable 2 to rotate, and a group of profiling turntables 2 for fixing workpieces 5 Clamping and positioning mechanism 3, the clamping and positioning mechanism 3 is distributed on the edge of the profiling turntable 2 at intervals, wherein the periphery of the profiling turntable 2 where the clamping and positioning mechanism 3 is installed is provided with a profiling edge 8; wherein the clamping and positioning mechanism 3 includes The fixed seat 3-1 installed on the profiling turntable 2, the fixed seat 3-1 is movably connected with a lever 3-2, and the outer end of the lever 3-2 is provided with a pressing plate for clamping the workpiece 5 on the profiling turntable 2 3-3, the inner end of the lever 3-2 is placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com