Die with turn-up electromagnet pressing block

An electromagnet and flanging technology, which is applied in the field of molds with flanging electromagnet briquetting blocks, can solve problems such as unguaranteed product quality, unreliable glass fiber compaction, and difficult operation by workers, so as to reduce false application and improve Quality, avoid the effect of excessive pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

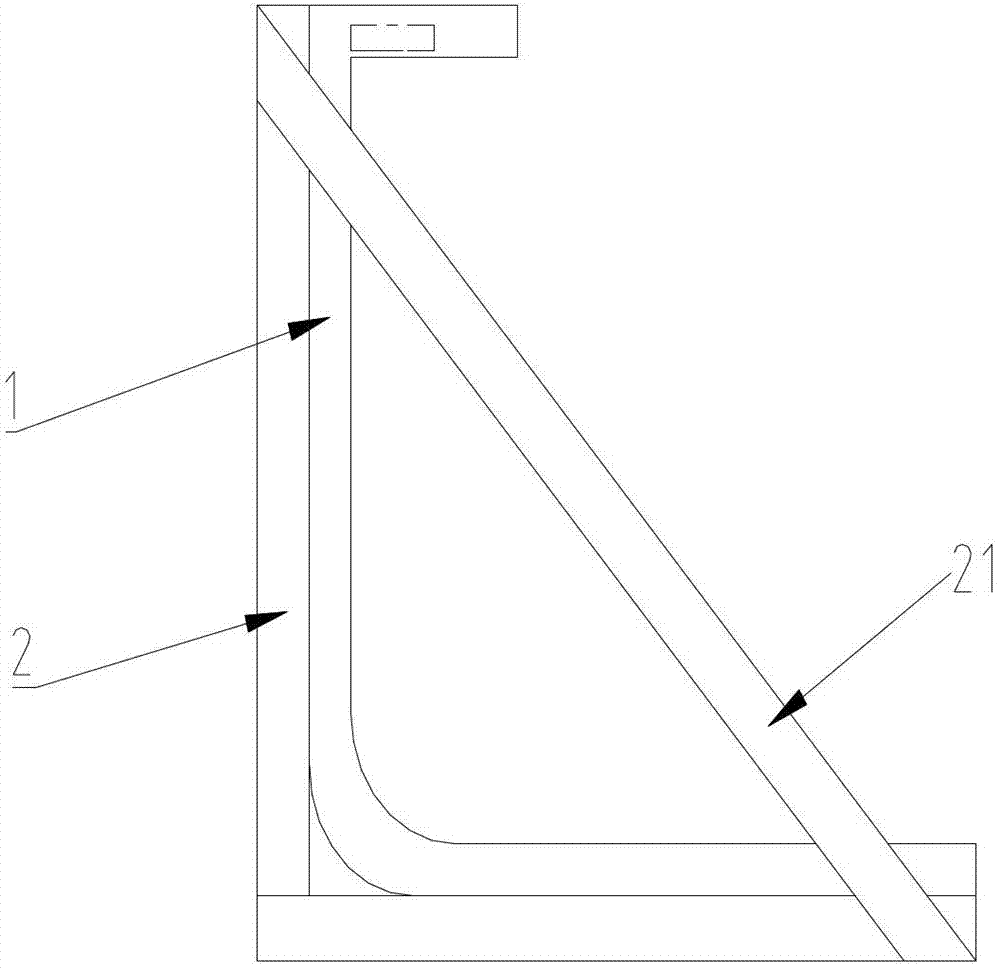

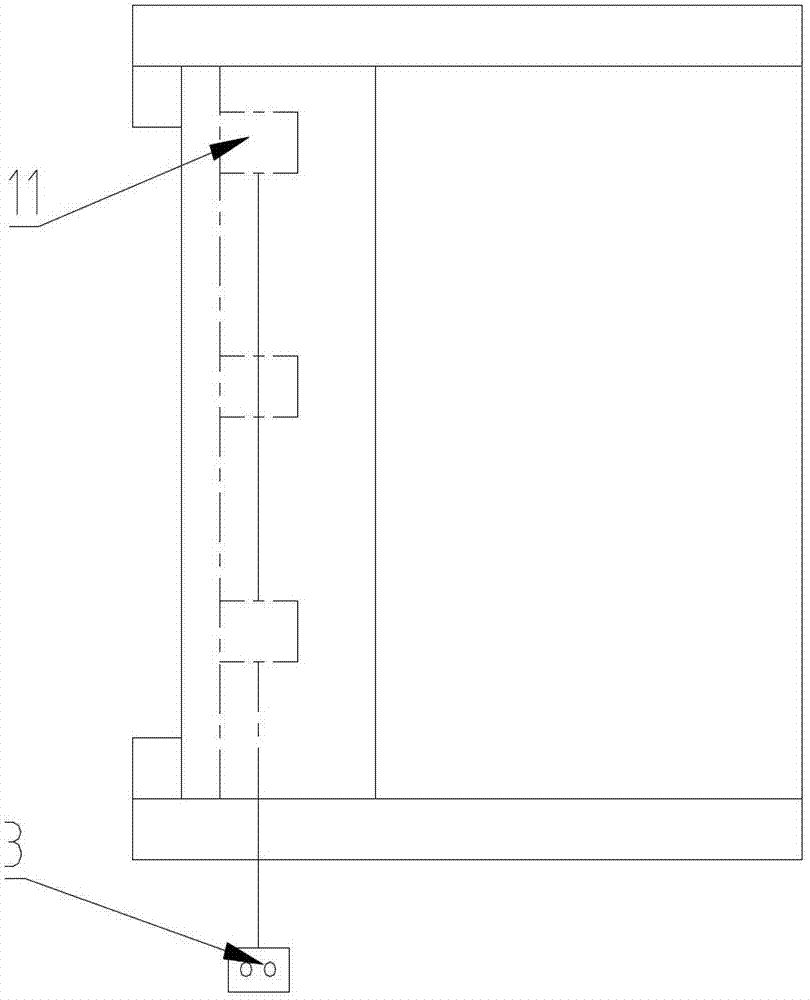

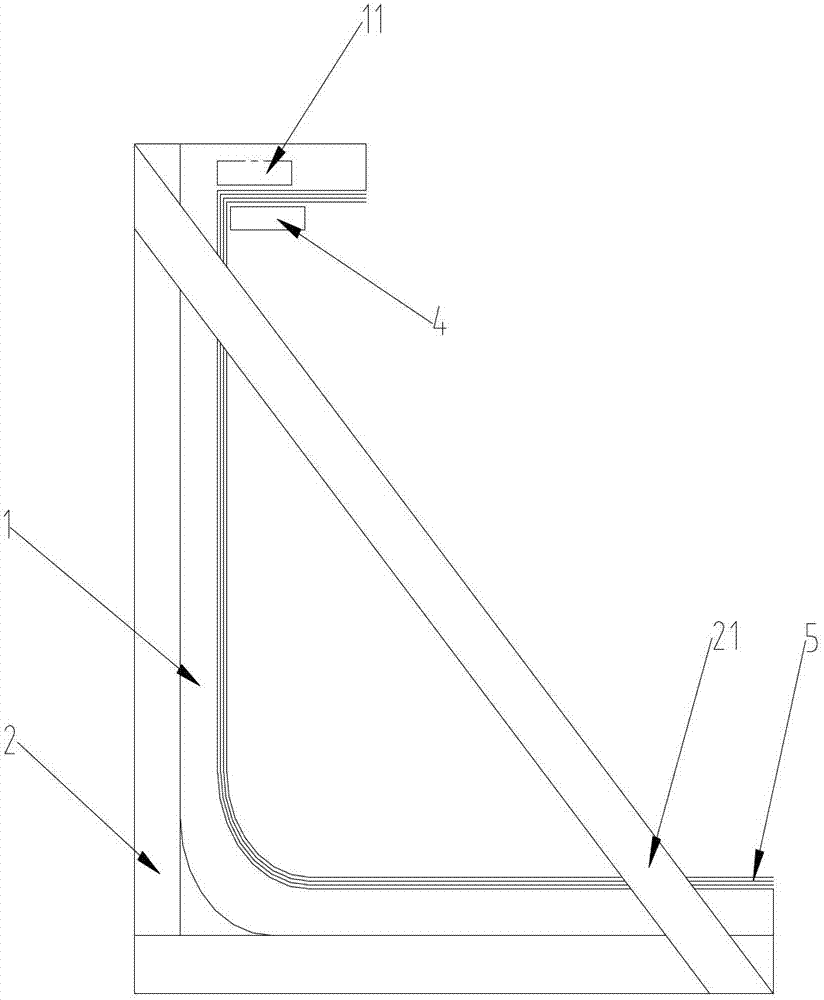

[0016] Such as Figure 1 to Figure 3 As shown, a mold with a flanging electromagnet briquetting block of the present invention includes a product female mold 1 and a female mold support structure 2, and is characterized in that: an electromagnet 11 is pre-embedded in the flange of the product female mold 1, and the electromagnet The 11 rooms are connected with built-in cables, the power control system 3 is connected with the electromagnet 11 embedded in the flange of the product female mold 1 through the power supply cable, and the suction force of the electromagnet 11 is adjusted through the power control system 3, and the product female mold 1 is fixed on the In the supporting structure 2 of the female mold, an internal movable strong magnet pressing block 4 for pressing against the glass fiber is also included.

[0017] Further, the support structure 2 of the female mold is welded by rectangular square tubes, in order to ensure the stability of the tooling, such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com