Suspension

A suspension and firmware technology, which is applied to vehicle components, jet propulsion devices, internal combustion propulsion devices, etc., can solve problems such as engine instability, poor installation stability, suspension failure, etc., to ensure installation stability, good bonding strength, The effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

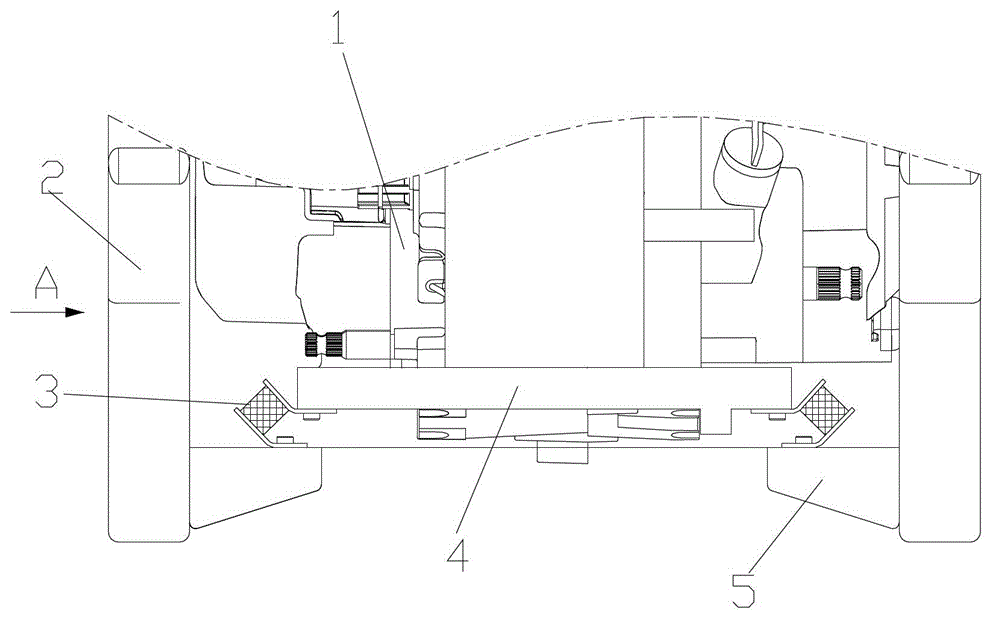

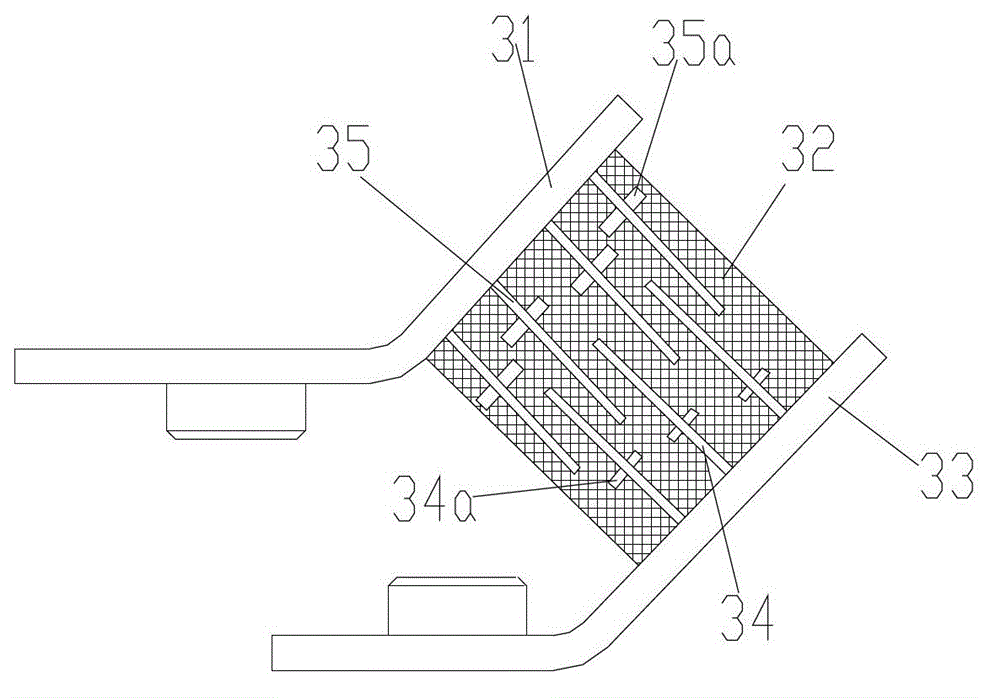

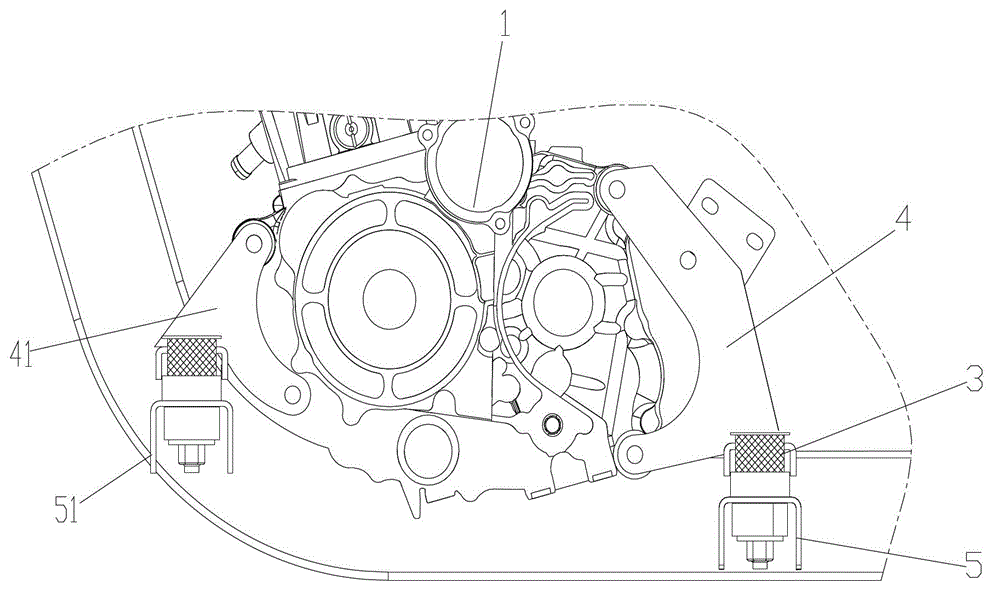

[0019] figure 1 It is a schematic diagram of the installation structure of the present invention, figure 2 It is a schematic diagram of the suspension structure of the present invention, image 3 for figure 1 View along direction A, as shown in the figure: the suspension of this embodiment includes an upper support plate 31, a lower support plate 33 and an elastic pad 32 fixed between the upper support plate 31 and the lower support plate 33, the elastic pad 32 is supported between the upper support plate 31 and the lower support plate 33 in an inclined manner; the upper support plate 31 and the lower support plate 33 are respectively provided with handles that extend into the elastic pads to form a solid handle; The principle of fixing mainly depends on the frictional force and lateral blocking force between the hardware and the elastic pad; The firm handle; the principle of the fix is mainly to rely on the friction force and lateral blocking force between the handle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com