Device for stacking and bundling packing boards and operation method

A technology for packaging cardboard and bundling device, which is applied in the directions of packaging, transportation and packaging of paper products, types of packaging items, etc., can solve the problems of irregular shape of packaging cardboard, large gap of packaging cardboard, and uncompact stacking, etc., so as to save stacking. The effect of stacking cost, improving utilization rate, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

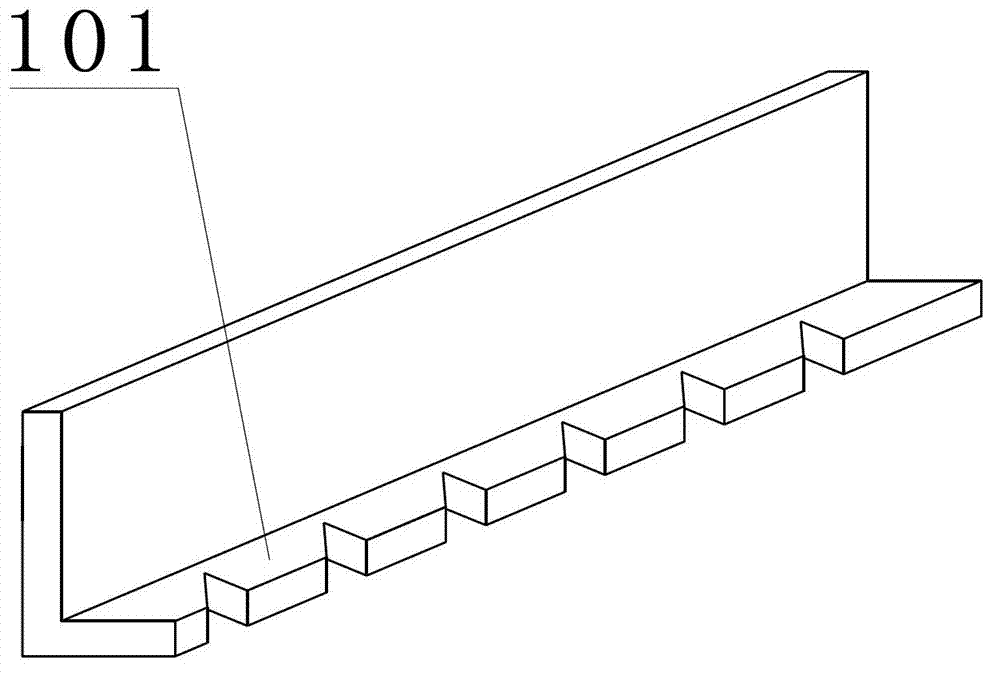

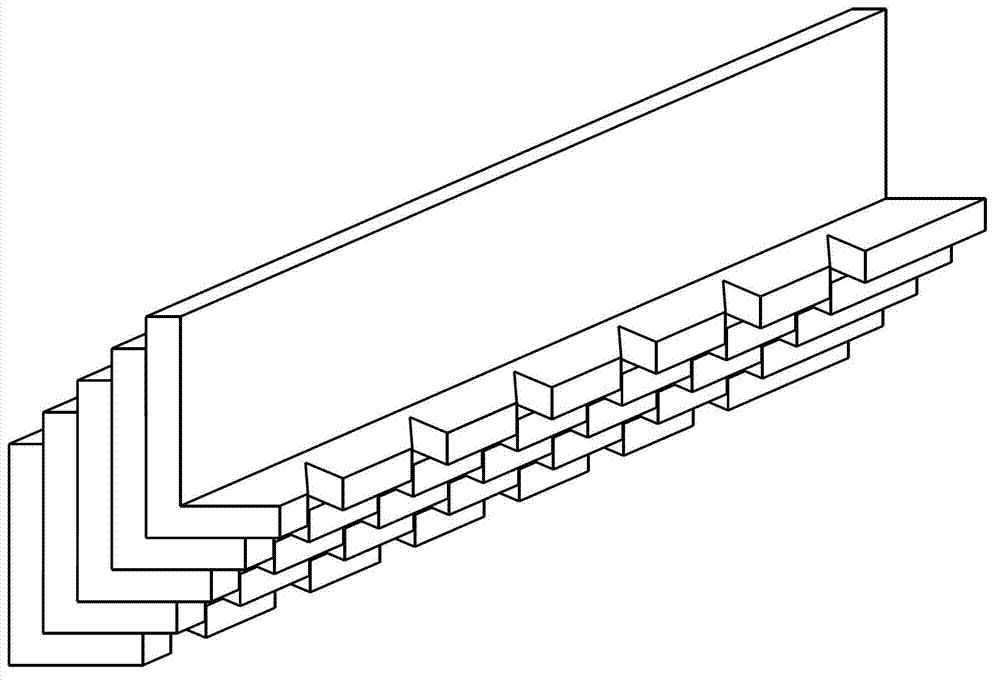

[0040] The packaging cardboard is a long strip of bent cardboard 1 with an "L" shape in cross section, and a plurality of "V"-shaped notches are set on the first side panel 101 at intervals, such as figure 1 shown.

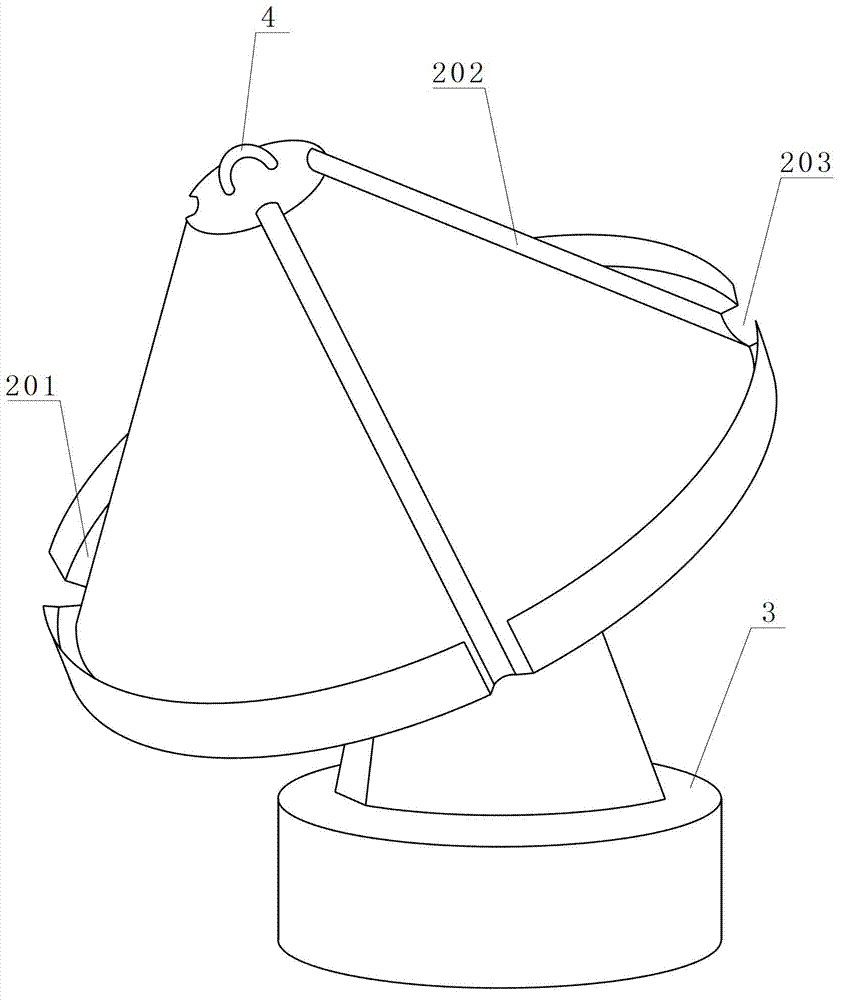

[0041] The device includes a frustum-shaped cardboard winding seat 2 and a bottom base frame 3 for installing the cardboard winding seat 2. The cardboard winding seat 2 and the bottom base frame 3 are rotatably connected, and the cardboard winding seat 2 can be mounted on the bottom base. Rotate around its own center line on the frame 3, and the center line of the cardboard circle seat 2 forms an included angle of 30~60 degrees with the horizontal plane.

[0042] On the vertical section where the center line of the cardboard coil seat 2 is located, the cross section of the cardboard coil seat 2 is an isosceles trapezoid. The space between the sides forms a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com