Method for neutralizing sulphur acidity by using refined lime

A technology of lime and sulfur, applied in the preparation/purification of sulfur, etc., can solve the problems of high price of soda ash, increase production cost, difficult to filter and separate, etc., and achieve the effect of reducing production cost, facilitating filtering and removing, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

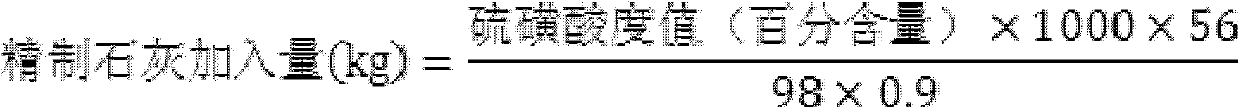

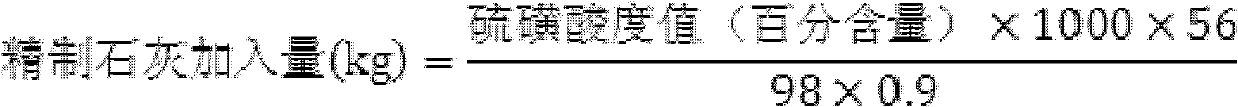

[0011] Embodiment 1: one ton of sulfur, through laboratory acid-base titration assay, its acidity value is 0.030%, through following formula calculation,

[0012]

[0013] Add 0.19kg of refined lime, stir well, filter to remove the residue, and then proceed to the next step of production.

Embodiment 2

[0014] Example 2: One ton of sulfur, tested by acid-base titration in the laboratory, has an acidity value of 0.063%. After calculation, add 0.4 kg of lime, fully stir, filter to remove the residue and proceed to the next step of production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com