Composition for preparing highly-conductive flame retardant plastic, highly-conductive flame retardant plastic prepared thereby and preparation method thereof

A technology of flame retardant plastic and composition, applied in the field of polymer composite materials, can solve the problems of unsafe use, low flame retardant level, etc., and achieve the effects of easy processing and molding, high flame retardant level and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

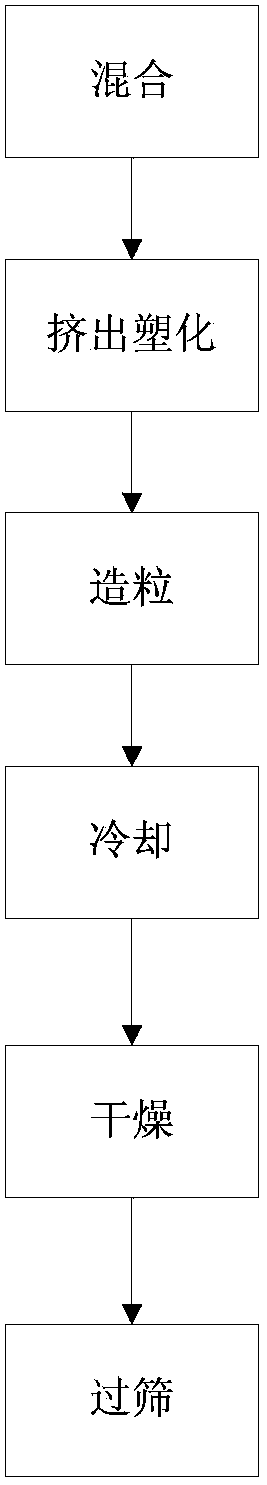

[0041] The present invention also provides a method for preparing the above-mentioned high-conductivity flame-retardant plastic, including the steps of mixing, extruding and plasticizing, granulating, cooling, drying, and sieving. The mixing steps are:

[0042] 1) Mix the conductive material at 300-500r / min for 3-5min at a temperature of 90-110°C to obtain the first conductive material, wherein, based on the mass of the conductive material, the conductive material includes 65-78wt% linear low-density polyethylene, 5~10wt% polyolefin elastomer, 10~20wt% superconducting carbon black, 1~2wt% coupling agent, 1~3wt% zinc stearate, 1~3wt% polyethylene wax, 0.2~0.4wt% antioxidant agent, 1~3wt% bis stearamide, 2~5wt% sizing agent and 0.02~0.1wt% initiator.

[0043] 2) Mixing the first conductive material at 180-210° C. and 800-1200 r / min for 5-10 minutes to obtain the second conductive material.

[0044] 3) The second conductive material is melted and plasticized to obtain a molten m...

Embodiment 1~5

[0053] Combine the conductive material and the flame retardant material according to the recipes of Examples 1 to 5 and Comparative Example 1, put the conductive material and the flame retardant material into the mixer according to the ratio of 88:12, and mix them in the mixing machine. In a single-stage single-screw, extruding and plasticizing at 180 ° C to obtain a flame-retardant conductive plastic. Table 1 is the type and content of the prescriptions of Examples 1-5 and Comparative Example 1.

[0054] Processing performance: Symbol I indicates that the material is easy to process, and the material components do not migrate, do not dissociate, and do not dialysis; Symbol II indicates that hydrogen bromide and free bromine are produced, with high viscosity, easy to stick to the screw and die head, and there is a lot of retained material, which is not easy to clean. clear.

[0055] Flame retardant grade: According to the ZA-306.1-2007 standard, it is divided into four catego...

Embodiment 6

[0060]1) Mix 88% of the conductive material in Example 1 at 180°C at 500r / min for 3 minutes to obtain the first conductive material; mix the first conductive material at 180°C at 1200r / min for 5min to obtain the second Conductive material: transporting the second conductive material to the hopper of a twin-screw extruder, performing a melting and plasticizing step at a temperature of 220° C. and a pressure of 0.5 MPa to obtain a molten material;

[0061] 2) Stir 12% of the flame retardant material in Example 1 at room temperature at 50 r / min for 2 minutes to obtain the first flame retardant material;

[0062] 3) Adding the first flame retardant material to the molten material to obtain a mixed material.

[0063] 4) The mixed material was transported to the hopper of a single-screw extruder, and the melting and plasticizing step was carried out at a temperature of 200° C. and a pressure of 8 MPa to obtain a plasticized material.

[0064] 5) Cut the plasticized material into pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com