High-temperature prevention axial expansion joint

A technology for preventing high temperature and expansion joints. It is used in expansion compensation devices for pipelines, thermal insulation, pipes/pipe joints/pipes, etc. It can solve the problem that expansion joints are easily damaged, lose elastic compensation, and thin-walled corrugated pipes are prone to instability. and other problems to achieve the effect of avoiding overheating instability, reducing thermal influence, and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

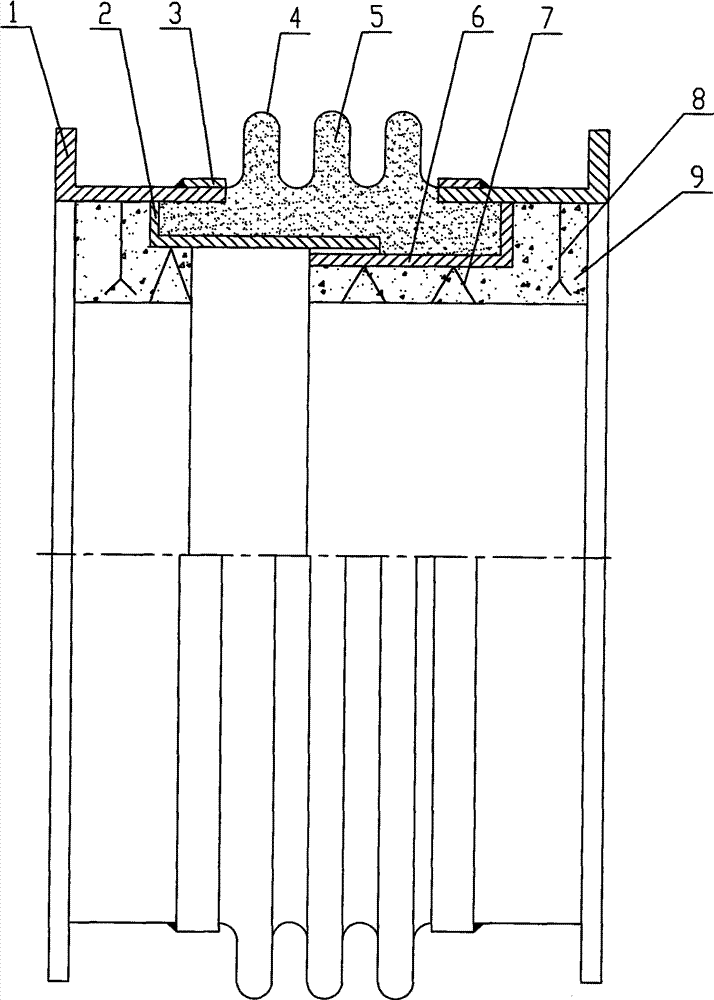

[0013] The embodiment of the anti-high temperature axial expansion joint shown in Figure 1 has a diameter of 5060 mm, which includes a connecting pipe 1, a left diversion pipe 2, a sheath 3, a bellows 4, a packing 5, a diversion pipe 6, and a short anchor 7 , long anchor nail 8 and lining material 9. Described connecting pipe 1 and left diversion pipe 2, right diversion pipe 6 all are the straight-through round pipes that one end is provided with flange edge, and left diversion pipe 2 and right diversion pipe 6 have one end of flange edge outwards to make the same Shaft fitting, the connecting pipe 1 on the left side is set on the outer wall of the flange side of the left draft tube 2 and is sealed and connected, and the connecting tube 1 on the right side is set on the outer wall of the flange side of the right draft tube 6 and is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com