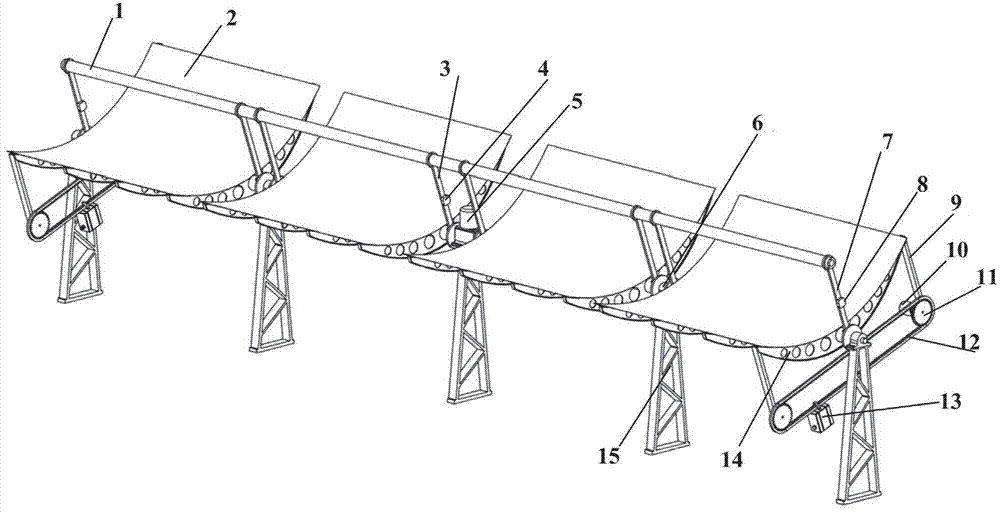

Self-adaptive torque compensation device and working method of trough-type solar collector

A trough solar and torque compensation technology, applied in solar collectors, solar collector controllers, solar thermal devices, etc., can solve problems such as torque imbalance, achieve efficient work, ensure tracking accuracy, and improve tracking accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

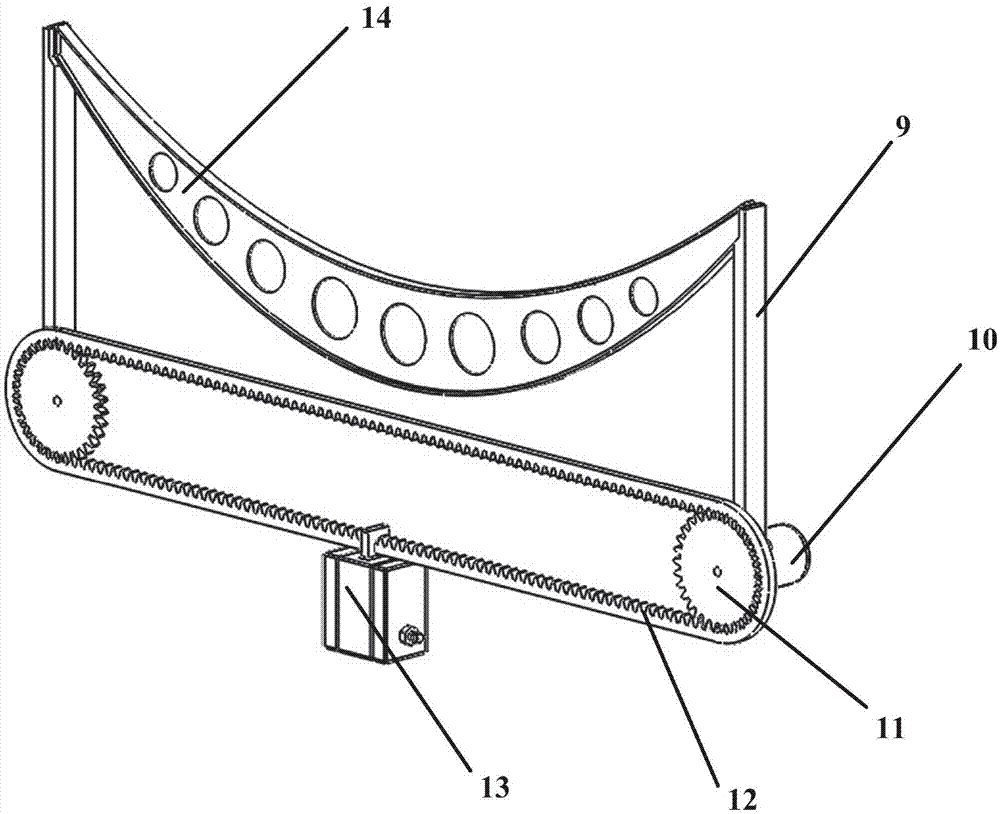

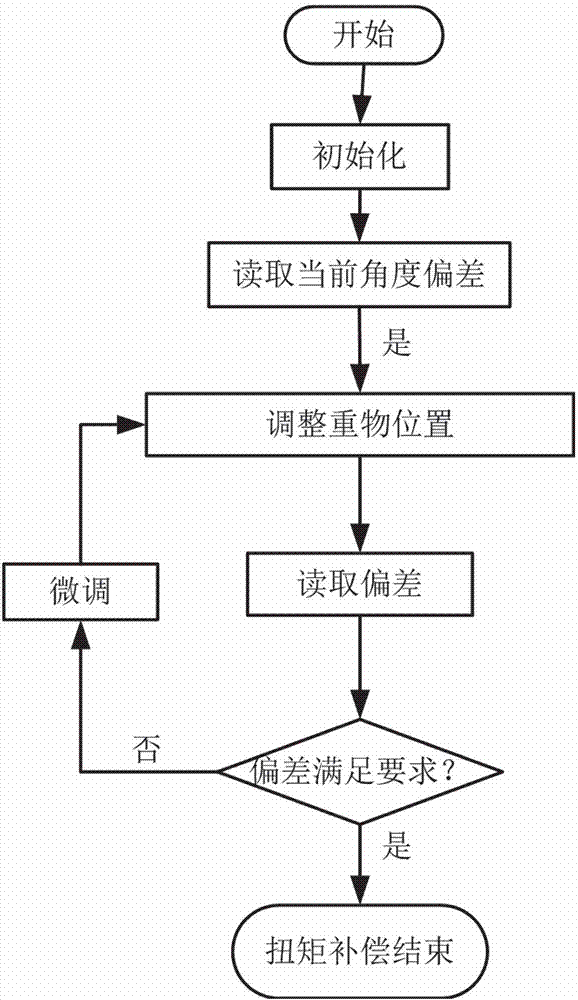

[0035] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS When the main motor 5 drives the heat collector to rotate around the main shaft 6, read the values of the angle sensors arranged on the central heat collecting tube support and the heat collecting tube supports at both ends, and obtain the deflection angle of the two ends of the axis and the deflection angle of the central axis, According to the angle deviation signal between the deflection angle of the end shaft and the deflection angle of the central shaft, the synchronous motor 10 at the corresponding end is driven to drive the synchronous wheel 11 to rotate, so that the synchronous belt 12 drives the weight 13 to move in the corresponding direction to compensate the torque. The torque compensation process ends when the angle deviation returned by the central angle sensor 4 and the end angle sensor 8 is zero.

[0036] Signal transmission is realized between the angle sensor and the synchronous motor through wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com