Reduction Tank Automatic Quantitative Binning Device

A technology of reduction tank and quantitative bin is applied in the field of automatic quantitative binning device of reduction tank, which can solve the problems of energy waste, low loading efficiency, large workload of workers, etc., and achieves improved production efficiency, convenient unloading, and accurate material distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

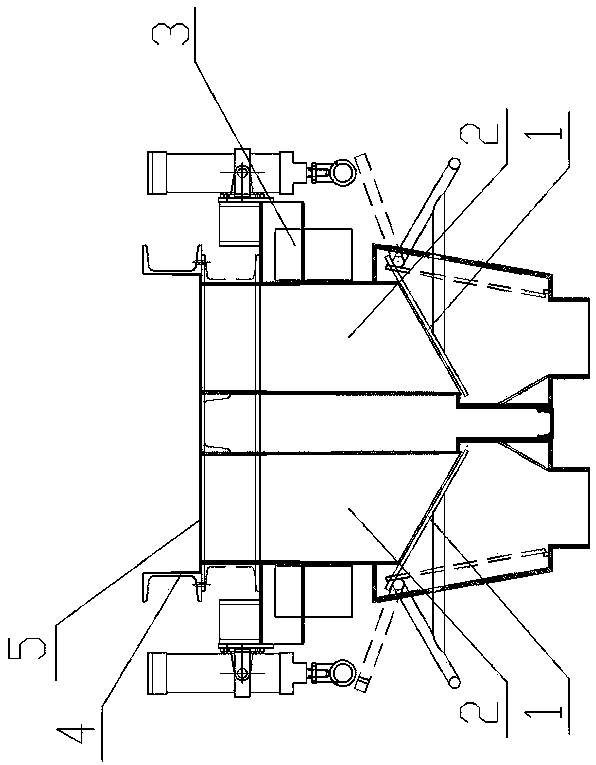

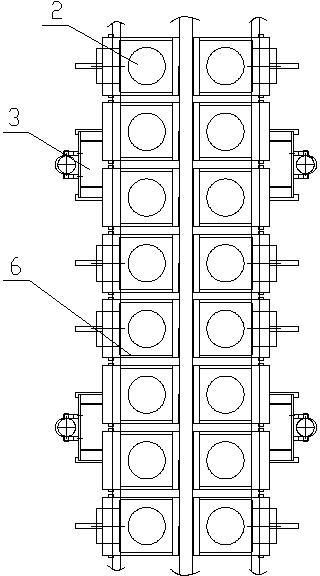

[0011] An automatic quantitative loading device for reduction tanks, including two sets of feeding devices arranged above the kiln car, each set of feeding devices includes a beam and two rows of bins 6 below the beam, each row of bins 6 is equipped with a kiln car Each row of reduction tanks on the top corresponds to several quantitative bins 2 one by one. The beam above the bin 6 is provided with a cloth track 4, and a reciprocating cloth distribution mechanism is installed on the cloth rail 4; the bottom of each quantitative bin 2 is provided. The material port and the discharge port are equipped with a discharge flap valve 1, and the top of each quantitative bin 2 is provided with a material inlet, and a cover plate 5 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com