Site direct-shearing rheological testing method and device

A rheological test, on-site technology, applied in the direction of using a stable shear force to test the material strength, using a stable tension/pressure test to test the material strength, etc., to achieve the effect of reliable performance, saving test costs, and making full use of on-site resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

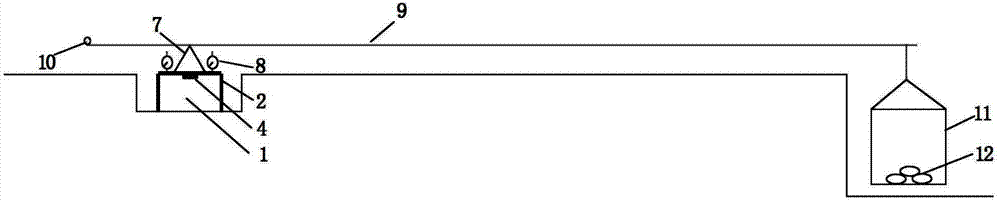

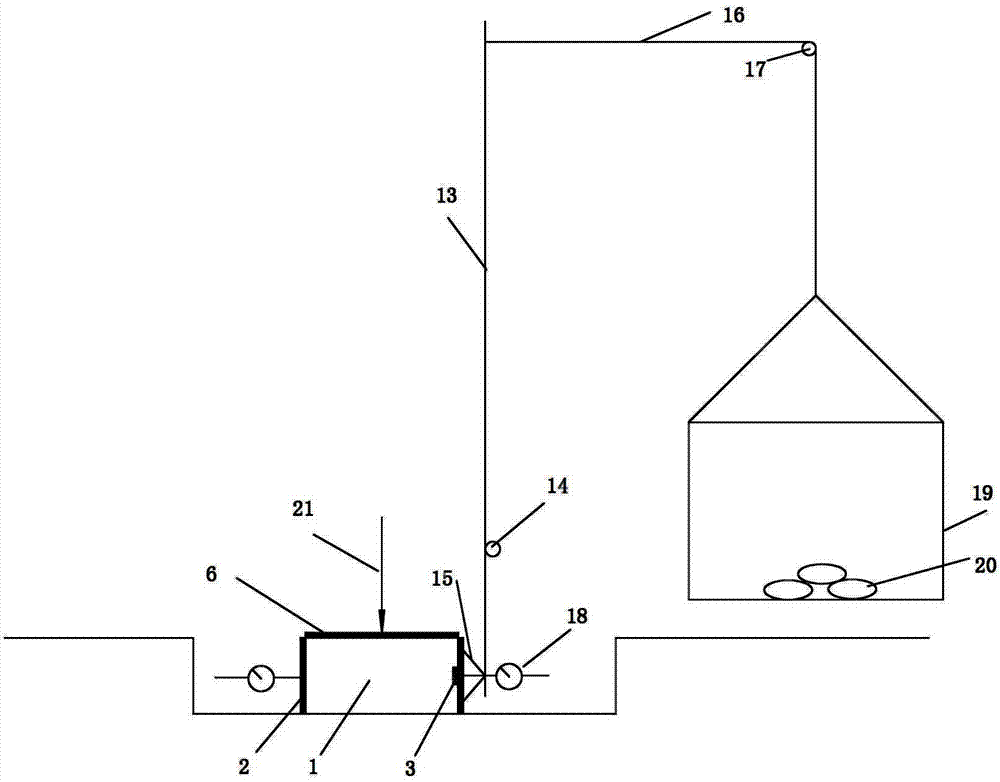

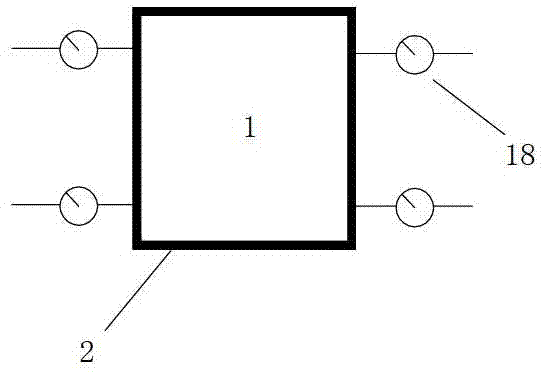

[0016] The specific implementation of the on-site direct shear rheological test device in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] see figure 1 , figure 2 with image 3 , the size of the earth column 1 is greater than 50cm × 50cm, less than 150cm × 150cm, the height of the earth column 1 is half of the side length, side rigid plates 2 are installed around the earth column 1, and the top of the earth column 1 is covered The top rigid plate 6 with the first tripod 7 is welded, and a side pressure cell 3 is pre-embedded on the horizontal shear loading side for testing the horizontal compressive stress, and a top pressure cell 4 is pre-embedded on the top of the earth column 1 for testing the vertical stress. To the pressure, put the horizontal lever 9 on the first tripod 7, one end of the horizontal lever 9 is placed under the first fixed bracket 10 as a rotation point, and the first reinforcement cage 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com