Impact tension testing apparatus

A technology of tensile test and pulse generating device, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as manufacturing difficulties, and achieve the effects of low structural sealing requirements, high success rate, and large gas output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

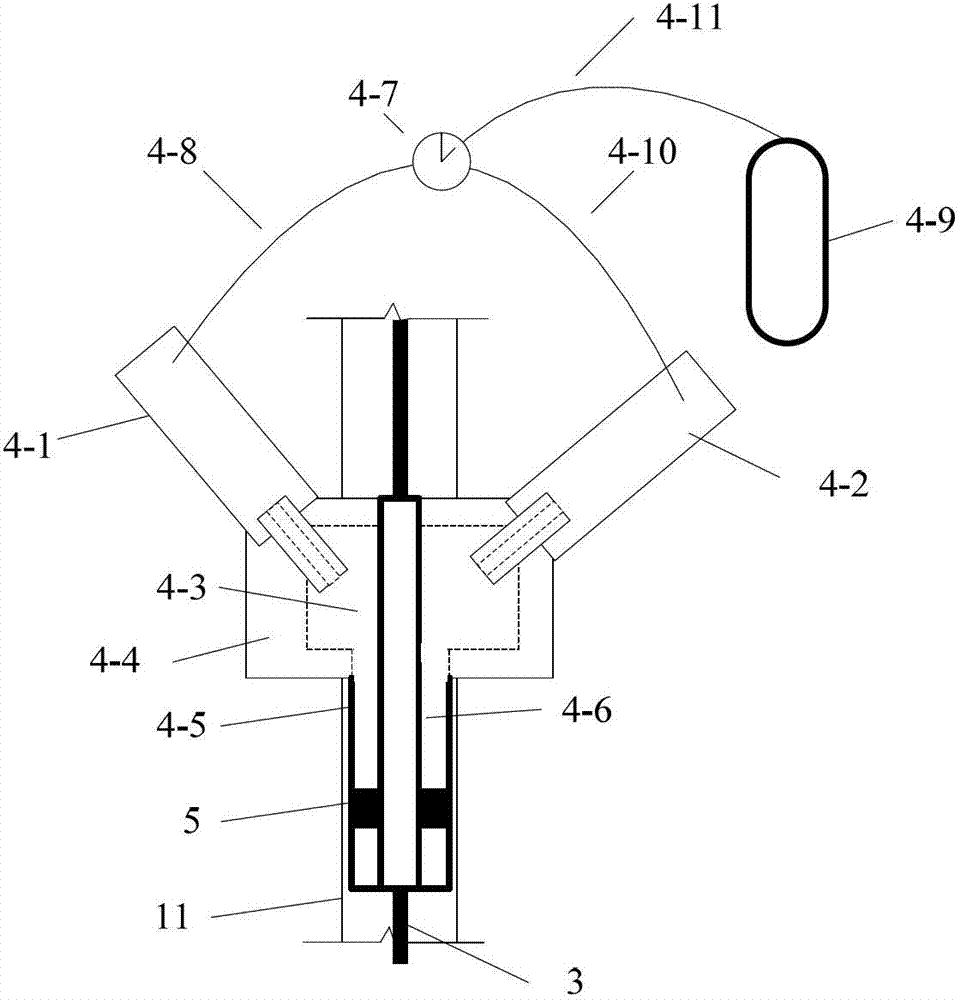

[0027] combine Figure 1-10 , the present invention is composed of a support base 11, a transmission rod 1, a test piece 2, an incident rod 3, a power generator 4, an annular collision block 5, a signal trigger device 7, a time interval meter 8, an absorption device 10, a strain gauge 12, a strain gauge Sheet 13, ultra-dynamic strain gauge 14, dynamic signal storage device 15, concrete base 6, and pulse generating device 9. It is characterized in that the transmission rod 1 is located on the left side of the base 11, the right end of the transmission rod 1 is connected to the left end of the test piece 2, the strain gauge 12 is pasted on the middle part of the transmission rod 1, and is connected with the ultra-dynamic strain gauge 14 through a wire, and the test piece 2. The right end is connected to the left end of the incident rod 3. The incident rod 3 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com