A kind of assay method of silicon content in ferromanganese

A method for measuring silicon content, which is applied in the field of analysis and testing, can solve problems such as difficult measurement, and achieve the effects of reliable method, good stability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

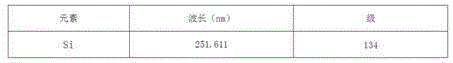

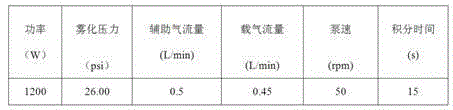

Image

Examples

Embodiment 1

[0015] Prepare each of the following standard solutions:

[0016] 1. Preparation of silicon standard solution:

[0017] 1A. Burn commercially available benchmark pure silica (above 99.9%) at 1000°C for 1 hour, cool and dry;

[0018] 1B. According to the amount of 10g mixed flux / g sample, add the above-mentioned dry silica to 4g mixed flux of anhydrous sodium carbonate and boric acid, heat and melt the sample at 950°C for 15min, and cool it into a frit, in which Mixed solvent is following mass ratio: the anhydrous sodium carbonate of 2 parts of quality: the boric acid of 1 part of quality, pulverizes and mixes;

[0019] 1C. Put the frit in step 1B into 100mL of water until completely dissolved, cool to room temperature, and dilute with water to obtain a silicon solution of 200 μg / mL to obtain a silicon standard solution, which is placed in a plastic bottle for later use;

[0020] 2. Preparation of silicon standard solution containing iron:

[0021] 2A. Weigh seven commercial...

Embodiment 2

[0028] Determination of silicon in ferromanganese sample to be tested:

[0029] 1. Preparation of ferromanganese sample solution to be tested:

[0030] 1A. According to the amount of 20g / g sample, add 2g of a mixture of anhydrous sodium carbonate and boric acid to 0.1000g of the ferromanganese sample to be tested, heat and melt the sample at 900°C for 15min to obtain 1.5g of molten sample, Wherein the mixture is the following mass ratio: anhydrous sodium carbonate: boric acid=2:1, ground and mixed;

[0031] 1B. Add 105mL of dilute hydrochloric acid to the 1.5g of molten sample in step 1A according to the amount of 70mL / g molten sample, and stir until the molten sample is completely dissolved to obtain 105mL of solution, wherein the volume ratio of diluted hydrochloric acid is as follows: HCl:H 2 O=1:3;

[0032] 1C. In the 105mL dissolving solution in step 1B, filter the dissolving solution with rapid quantitative filter paper, wash the funnel and the vessel with water for 5 ...

Embodiment 3

[0037] Determination of silicon in ferromanganese sample to be tested:

[0038] 1. Preparation of ferromanganese sample solution to be tested:

[0039] 1A. According to the amount of 30g / g sample, add 3g of a mixture of anhydrous sodium carbonate and boric acid to 0.1000g of the ferromanganese sample to be tested, heat and melt the sample at 950°C for 20min, and obtain 2g of molten sample, of which The mixture has the following mass ratio: anhydrous sodium carbonate: boric acid = 2:1, ground and mixed;

[0040] 1B. Add 150 mL of dilute hydrochloric acid to the 2 g of molten sample in step 1A according to the amount of 75 mL / g molten sample, and stir until the molten sample is completely dissolved to obtain 150 mL of solution, wherein the volume ratio of diluted hydrochloric acid is as follows: HCl:H 2 O=1:3;

[0041] 1C. In the 150mL dissolving solution in step 1B, filter the dissolving solution with rapid quantitative filter paper, wash the funnel and the vessel 8 times wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap