Manufacturing method of high-voltage alternating semiconductor LED (light-emitting diode) chips

A light-emitting diode, high-voltage AC technology, applied in semiconductor devices, electrical solid-state devices, electrical components, etc., can solve the problems of the whole chip not working properly, unfavorable for integrated chips, and occupying a large area, so as to reduce the occupied area and avoid Connection method, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation of the manufacturing method of the high-voltage AC semiconductor light-emitting diode chip of the present invention will be explained below in conjunction with the accompanying drawings. However, implementation of the present invention is not limited to the following embodiments.

[0045] Explanation: the accompanying drawings of the present invention are only schematic diagrams, and the representations in the drawings are only schematic in nature. In the drawings, in order to clearly reflect the principles and structures of the present invention, the thicknesses of layers and regions have been appropriately adjusted, and they are not strictly used as schematic diagrams. Reflecting the proportional relationship of aggregate size, therefore, the schematic diagram of the present invention cannot be used to limit the scope of the present invention.

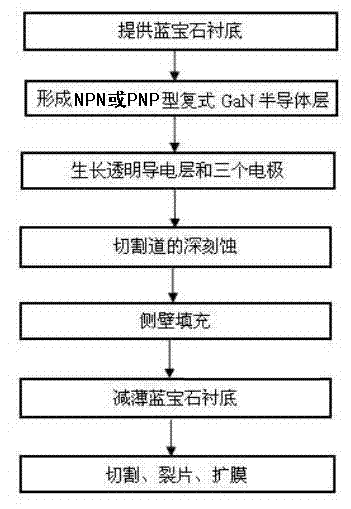

[0046] A method for manufacturing a high-voltage AC semiconductor light-emitting diode chip, com...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap