Automotive trim part for sound insulation and absorption

A sound isolation and sound absorption technology, which is applied to vehicle parts, transportation and packaging, and sound-emitting devices, can solve the problems of difficult recycling of discarded materials for parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

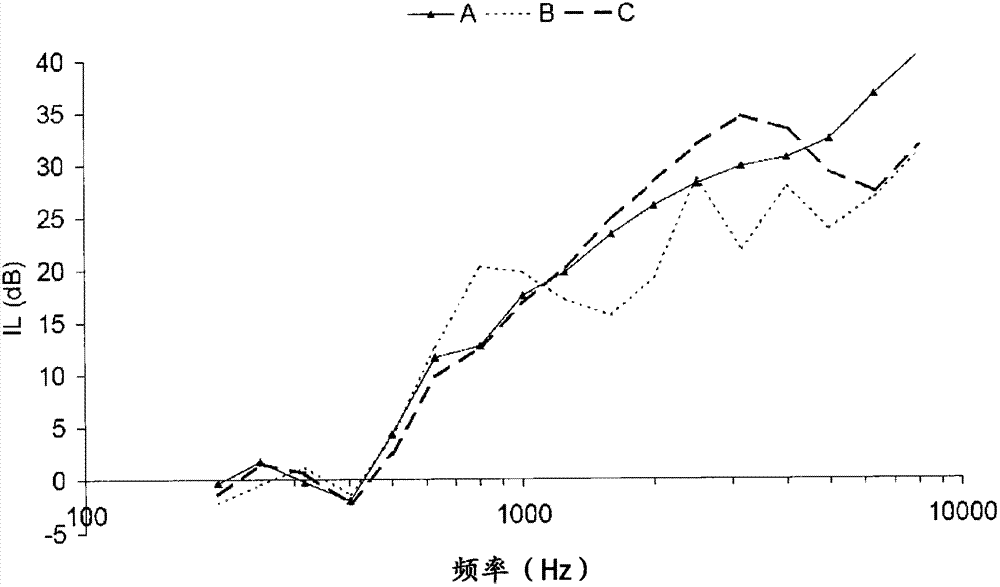

[0093] figure 1 Insertion loss curves for Comparative Samples A-B and Sample C are shown. The shown simulated insertion loss is the transmission loss of the system consisting of multiple layers and the steel plate to which the multiple layers are applied minus the transmission loss of the steel plate.

[0094] The sound absorption and insertion loss of different prior art noise attenuating multilayers were simulated using measured material parameters and compared with the insertion loss and sound absorption of the noise attenuating multilayer according to the present invention. All samples had the same overall thickness of 25 mm.

[0095] Comparative sample A is a typical mass-spring system, which has an area mass of 1(kg / m 2 ) mass layer made of EPDM thick layer material and injection molded foam as decoupling layer. The total area mass of A is 2370(g / m 2 ).

[0096] Comparative sample B was made according to the principles of patent EP1428656, which discloses a multila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com