Leakage-proof discharging structure of tobacco leaf loosening humidifier

A loose moisture regain and leak-proof technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of tobacco leaves floating out, turbulent flow of tobacco leaves, and lack of buffering of leaves, so as to prevent material leakage, improve production efficiency, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

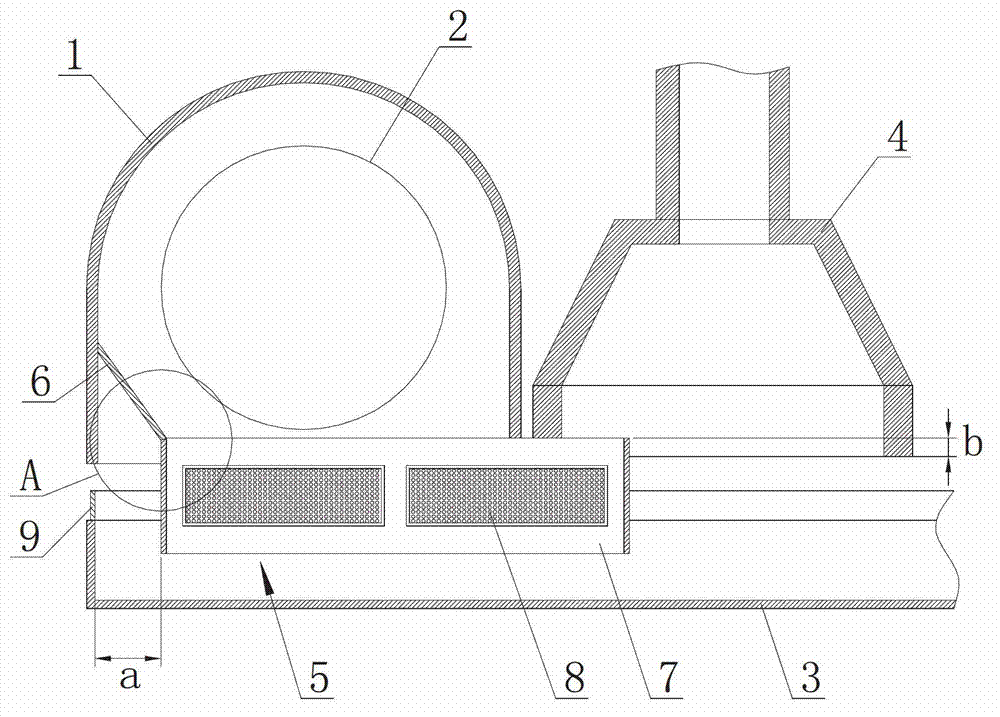

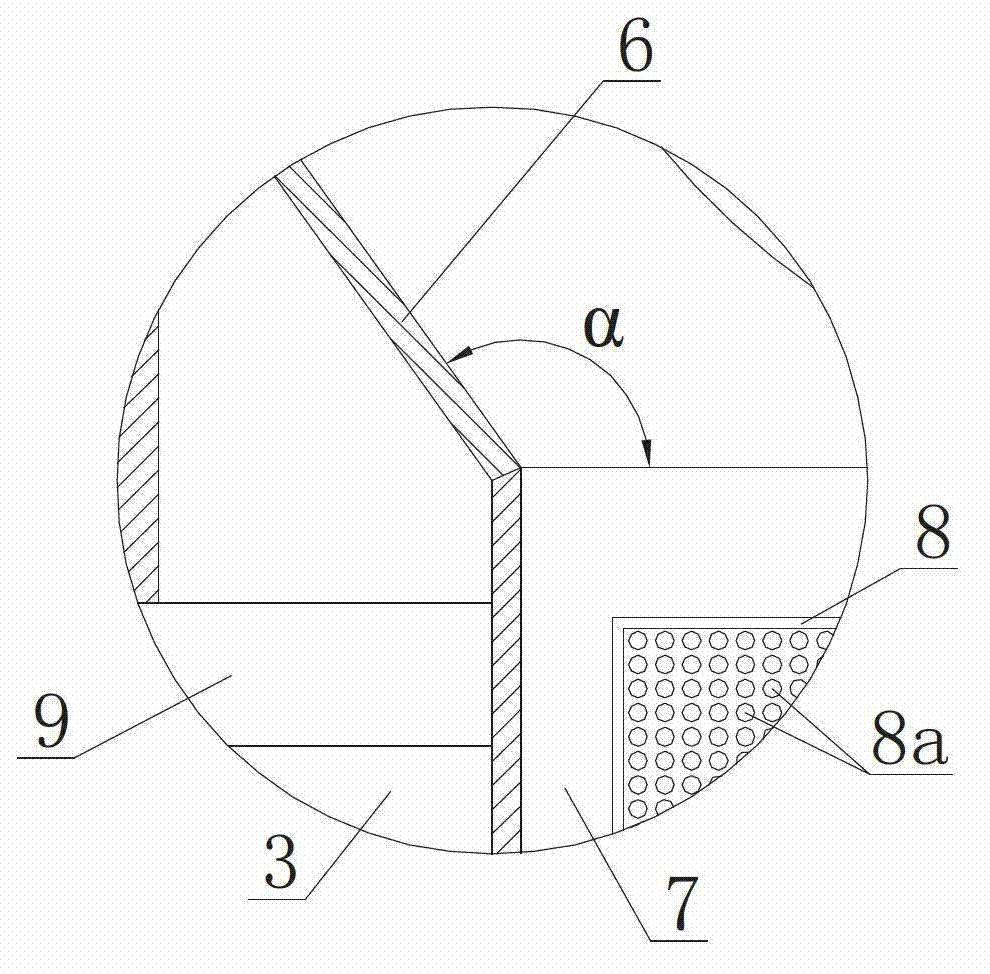

[0014] refer to figure 1 and figure 2 As shown, a discharge structure of a loose tobacco leaf dampening machine capable of preventing leakage of the present invention includes a body 1, a dampening cylinder 2 is provided in the body 1, and a vibrating groove 3 is provided below the discharge end of the dampening cylinder 2. A moisture discharge cover 4 is provided on the side of the moisture resurgence cylinder 2 along the length direction of the vibration tank 3, and a material guide cover 5 is provided on the body 1 at the discharge end of the moisture resurgence cylinder 2, and the lower end of the material guide cover 5 extends to the vibration tank 3 inside; the distance a between the discharge port of the material guide cover 5 and the rear end of the vibrating tank 3 is 400-700 mm, preferably 450-550 mm; the end of the material guide cover 5 opposite to the moisture discharge cover 4 extends Into the moisture discharge cover 4, the distance b between the upper end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com