Sizing method of high-waist leather boot barrel

A technology for boot shafts and leather shoes, applied to footwear, shoemaking machinery, clothing, etc., can solve problems such as uncomfortable wearing, no three-dimensional effect, irregular molding, etc., and achieve uniform opening specifications, smooth appearance, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

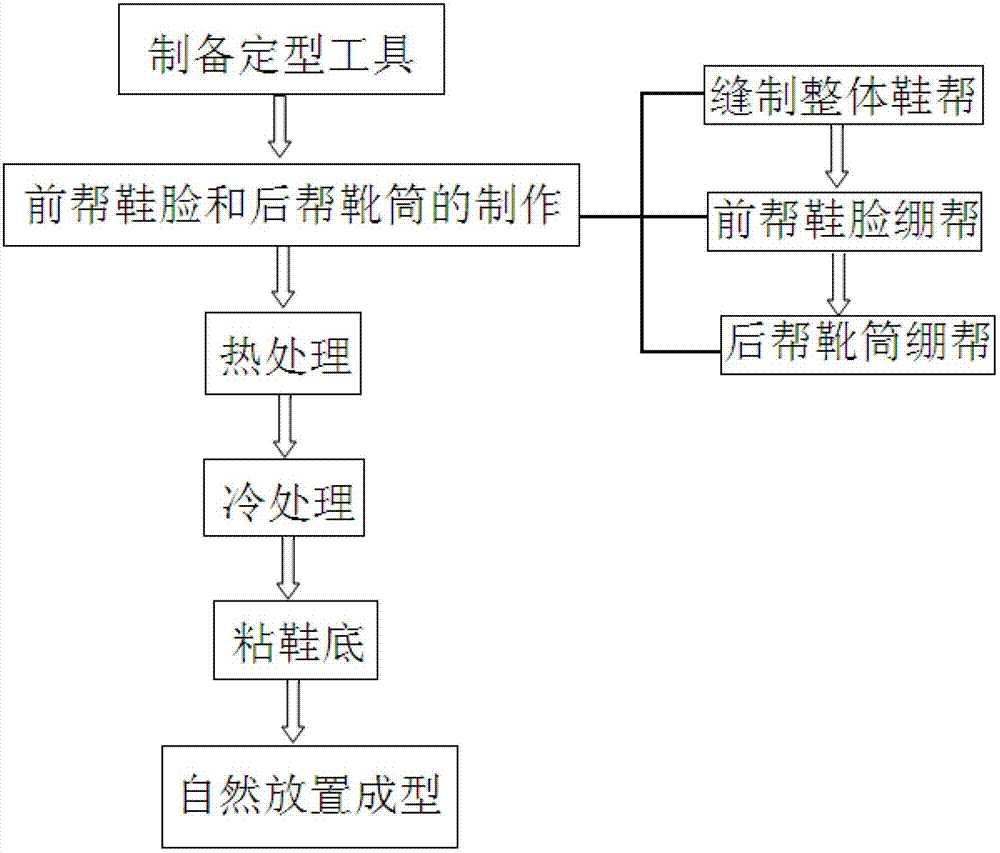

[0012] Such as figure 1 Shown, the inventive method comprises the following steps:

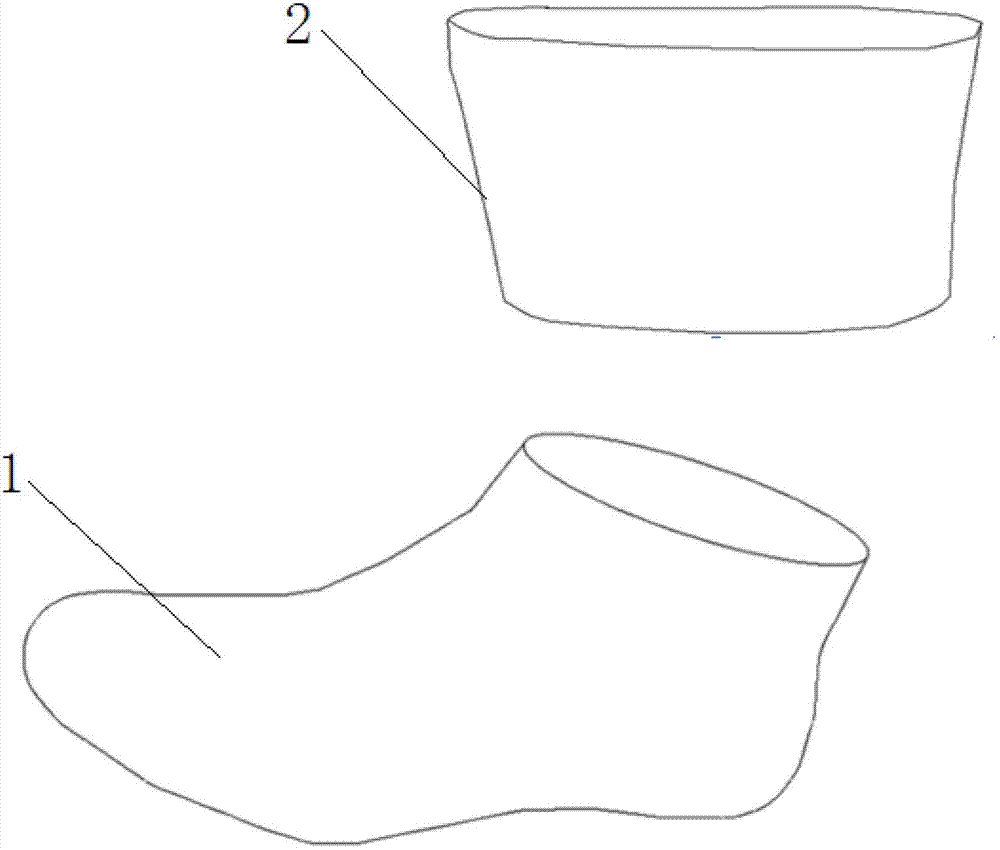

[0013] 1) Preparation of shaping tools: such as figure 2 As shown, prepare a shoe last 1 of a front shoe face similar to a shoe shape, a last row 2 of a rear boot shaft similar in shape to a boot shaft and a rectangular cardboard.

[0014] 2) Production of the front shoe face and the back boot shaft:

[0015] ① Sewing the whole shoe upper: Use a sewing machine to sew and connect the front shoe face part and the back boot shaft part to form a whole shoe upper, and install the main heel and inner toe cap.

[0016] ②The stretching of the front shoe face part: put the front shoe face part on the shoe last 1 and the insole of the front shoe face flatly and squarely, and the insole is located under the shoe last 1 of the front shoe face, Pull the upper part of the whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com