Material Conveying Devices for Presses

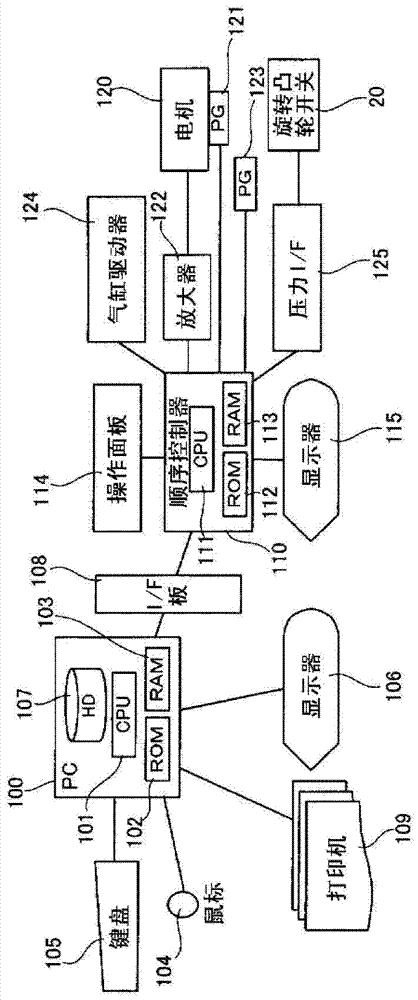

A material conveying device and press technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of difficult mechanical action, long time consumption, difficult identification of input data, etc., to improve reliability and efficient confirmation. and verification work, the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Hereinafter, Embodiment 1 of the present invention will be described with reference to the accompanying drawings.

[0050] A. The structure of the press:

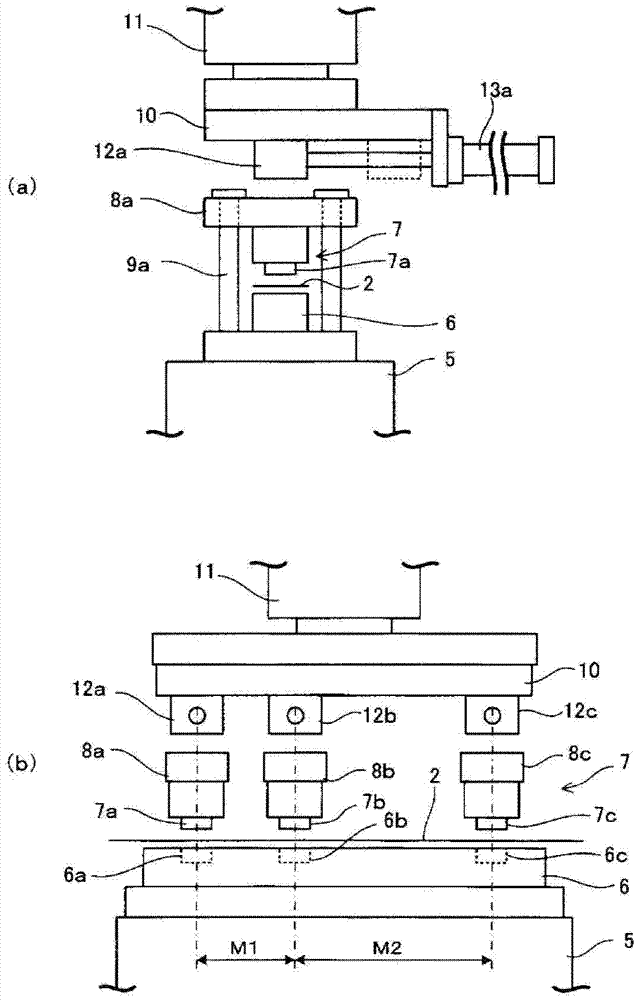

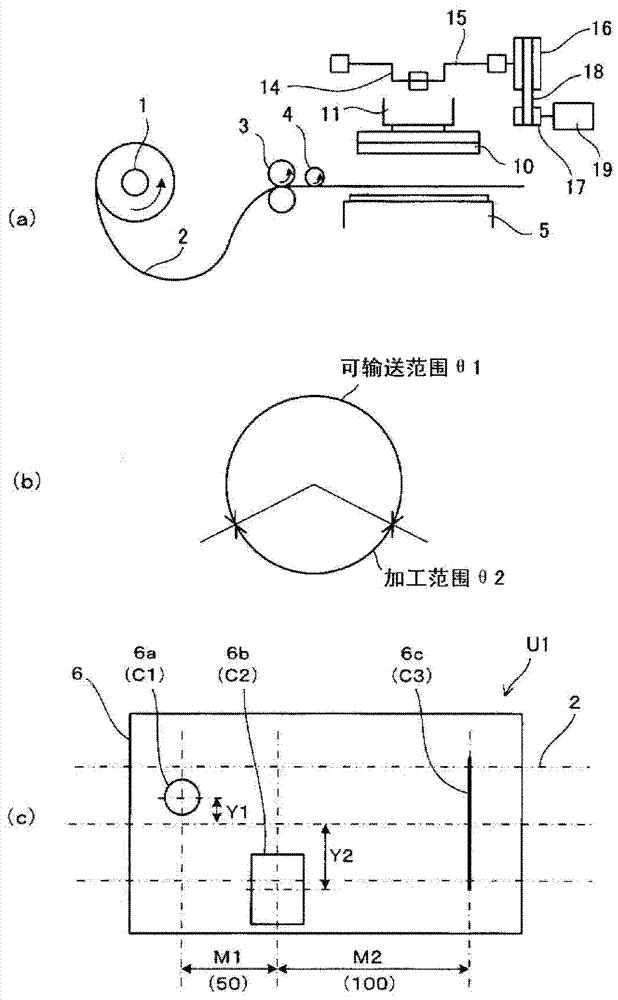

[0051] First, an example of a press will be described. figure 2 (a) is a side view of the main part of the press, (b) is a front view of the main part of the press, image 3 (a) is an overall configuration diagram of the press.

[0052] like image 3 As shown in (a), the coil 2 (material) unwound from the unwinding roll 1 at a predetermined unwinding speed (linear velocity) VL is fed out by a pair of feed rolls 3, and then introduced into the process as a process after passing through the measuring roll 4. on the base 5 of the table. Furthermore, if figure 2 As shown, a lower mold 6 is fixed on the base 5 , and an upper mold 7 is also arranged above the lower mold 6 . The upper mold|type 7 is divided|segmented in the conveyance direction of the coil 2, and becomes several processing mold|types 7a, 7b, 7c. Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com