Assembling device of automobile air conditioner fin die hobbing cutter

A technology for fin molds and automotive air conditioners, which is applied to assembly machines, manufacturing tools, and metal processing equipment. It can solve problems such as flange deformation, upper and lower flanges, and circular cutting blade misalignment, so as to avoid deformation, reduce production costs, and short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

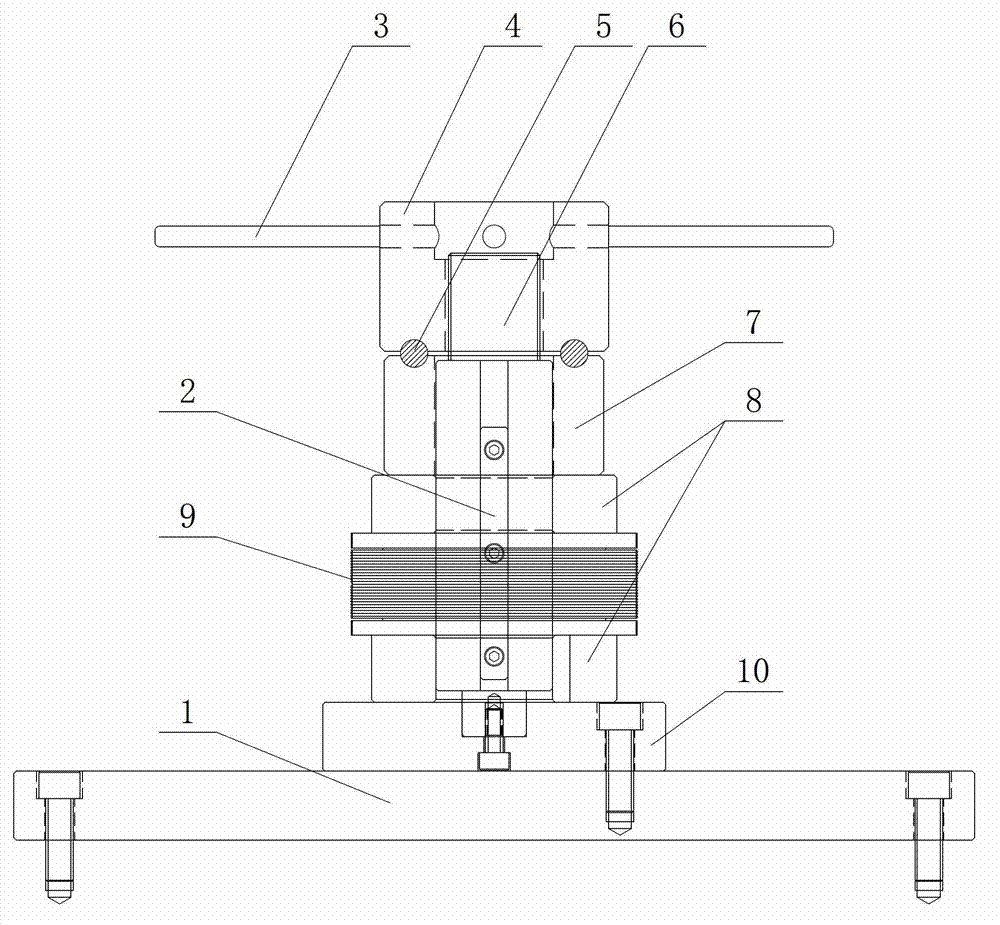

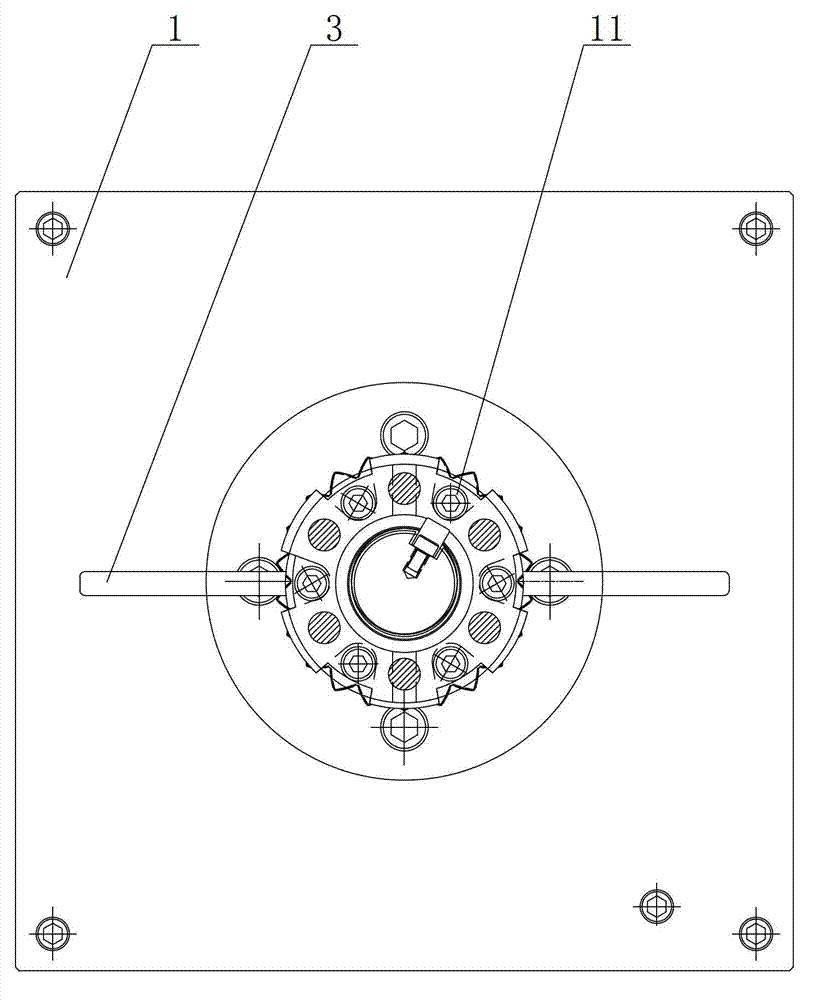

[0016] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

[0017] Please refer to figure 1 and figure 2 As shown, in this embodiment, an assembly device for a hob of an automotive air-conditioning fin mold includes a bottom plate 1, a mandrel 6 and a hob, the hob includes a flange 8 and an annular slice 9, and the bottom plate 1 is provided with an installation hole, the upper end of which is fixedly connected with a hob fixing seat 10, the hob fixing seat 10 is fixedly connected with the mandrel 6, and the hob is provided with a keyway, and the keyway is arranged on the mandrel 6. The upper end of the mandrel 6 is provided with a pressure device, and the pressure device includes a flat pressing wheel 4 threadedly connected with the mandrel 6 and a steel ball movably arranged on the mandrel 6 to keep the Frame 7, the plane pressing wheel 4 and the steel ball cage 6 are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com