Material receiving device for flat-tube cutting machines

A technology of feeding device and feeding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

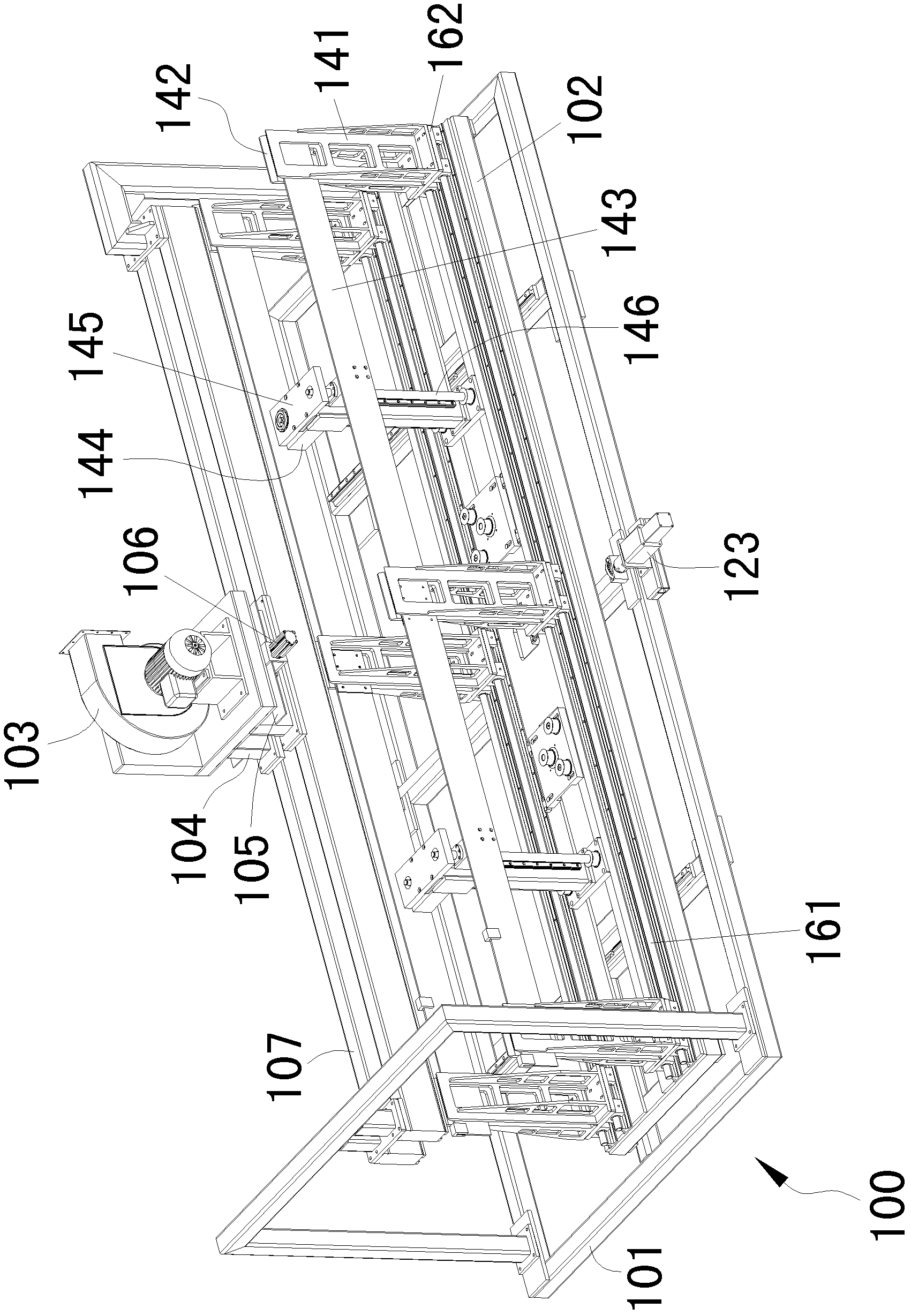

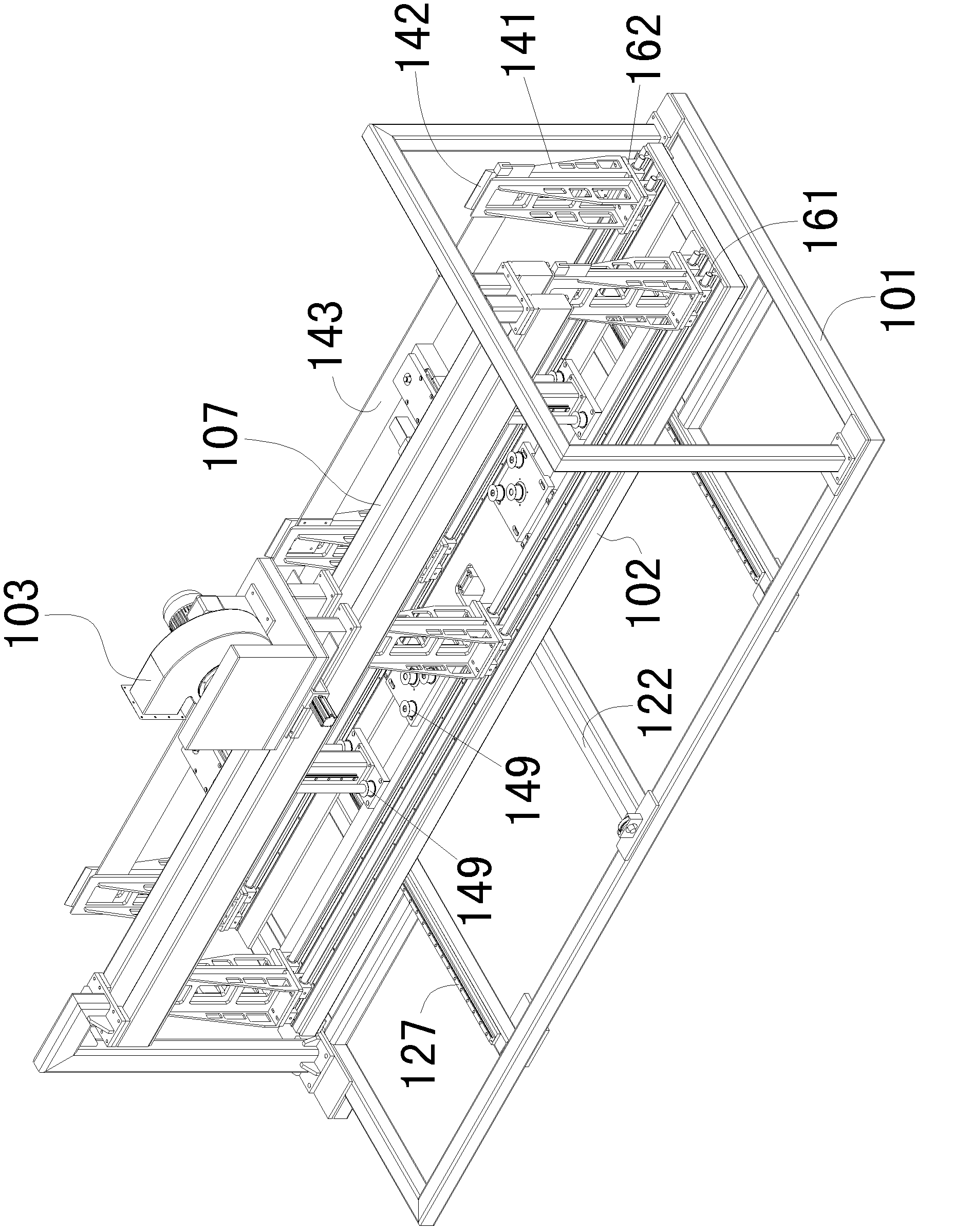

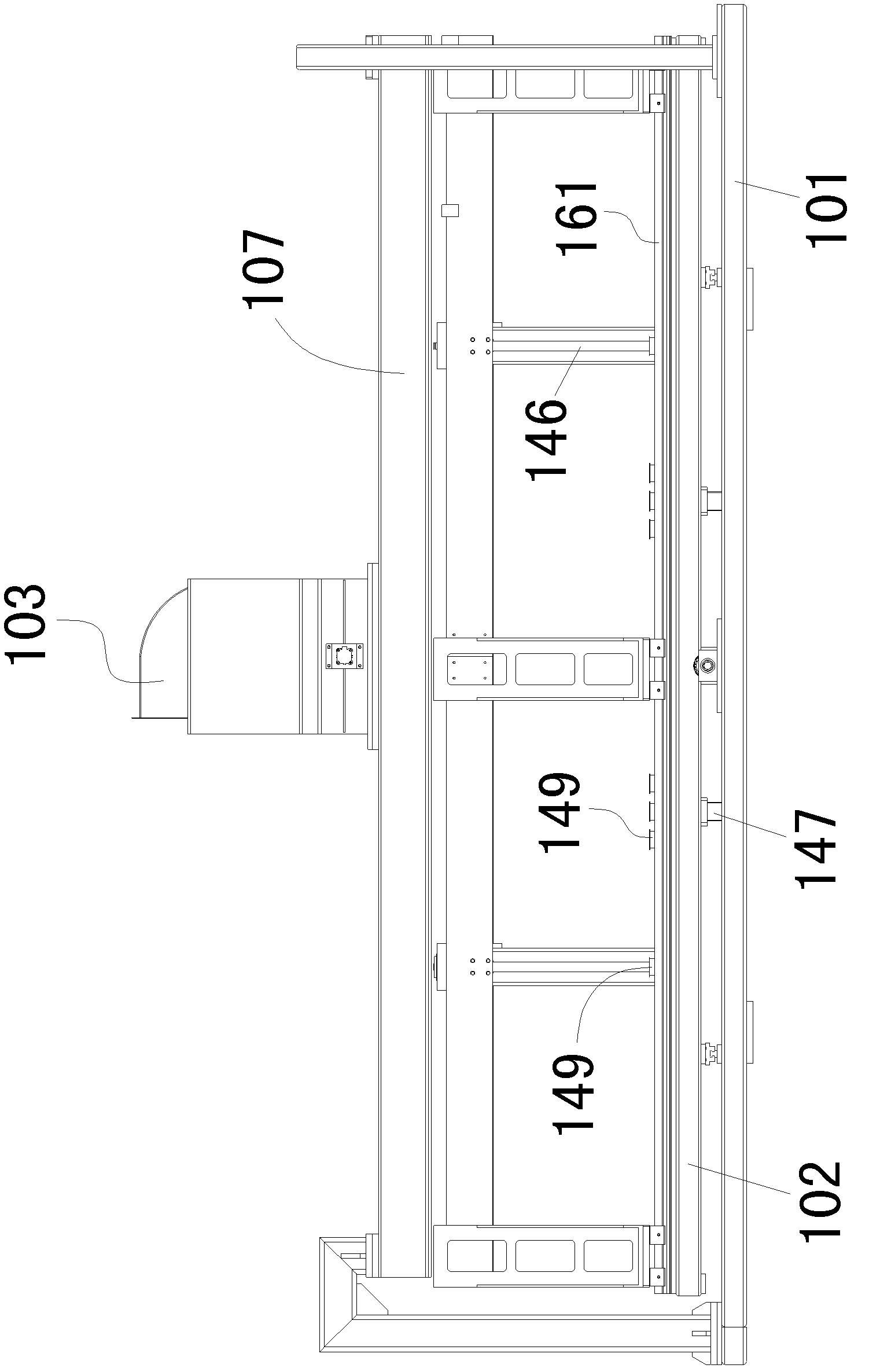

[0020] As shown in the figure, a material receiving device 100 of a flat tube blanking machine includes a material receiving frame 101, a material receiving platform 102, a traverse mechanism, a material holding mechanism and a material suction mechanism;

[0021] The material suction mechanism includes fan 103, air channel 104, wind blocking plate 105, air blocking cylinder 106 and suction cup 107. The suction cup is fixed on the top of the material receiving frame in the shape of a longitudinal beam. The lower end of the suction cup has a suction port 108. The fan is connected to The suction cup is used to generate suction at the suction port, and the choke cylinder is fixed on the side wall of the air duct. The piston rod of the choke cylinder is connected to the choke plate. The shape and size of the choke plate correspond to the section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com