Rotation and axial vibration synergic driving method and device for screw rod of directly-driven dynamic extruder

An axial vibration and dynamic technology, applied in the field of polymer material plasticizing and extrusion equipment, can solve the problems of large extruder volume and floor space, low energy utilization rate, poor operation stability, etc., and avoid multi-stage transmission. , the effect of reducing energy consumption and avoiding torque fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the scope described in the embodiments.

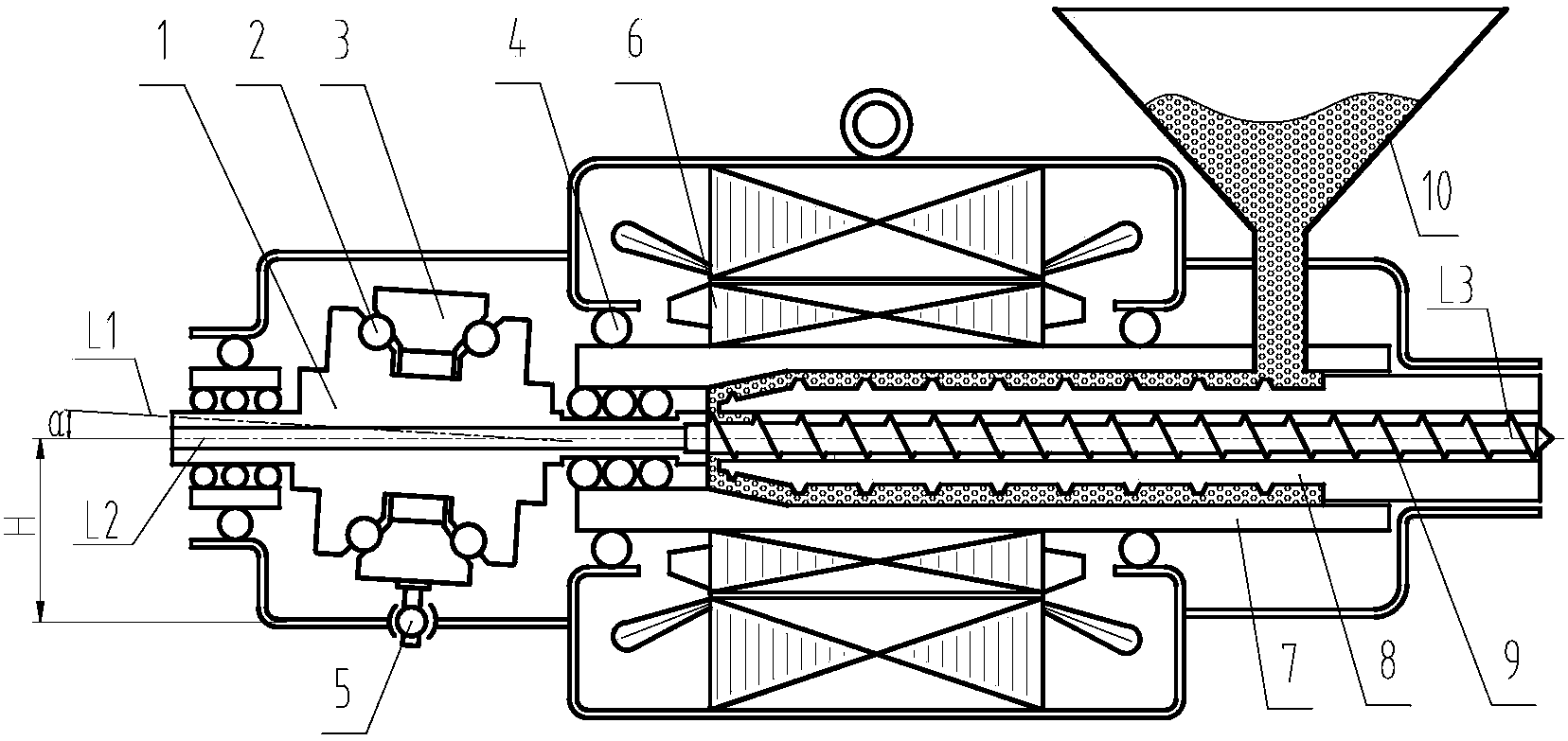

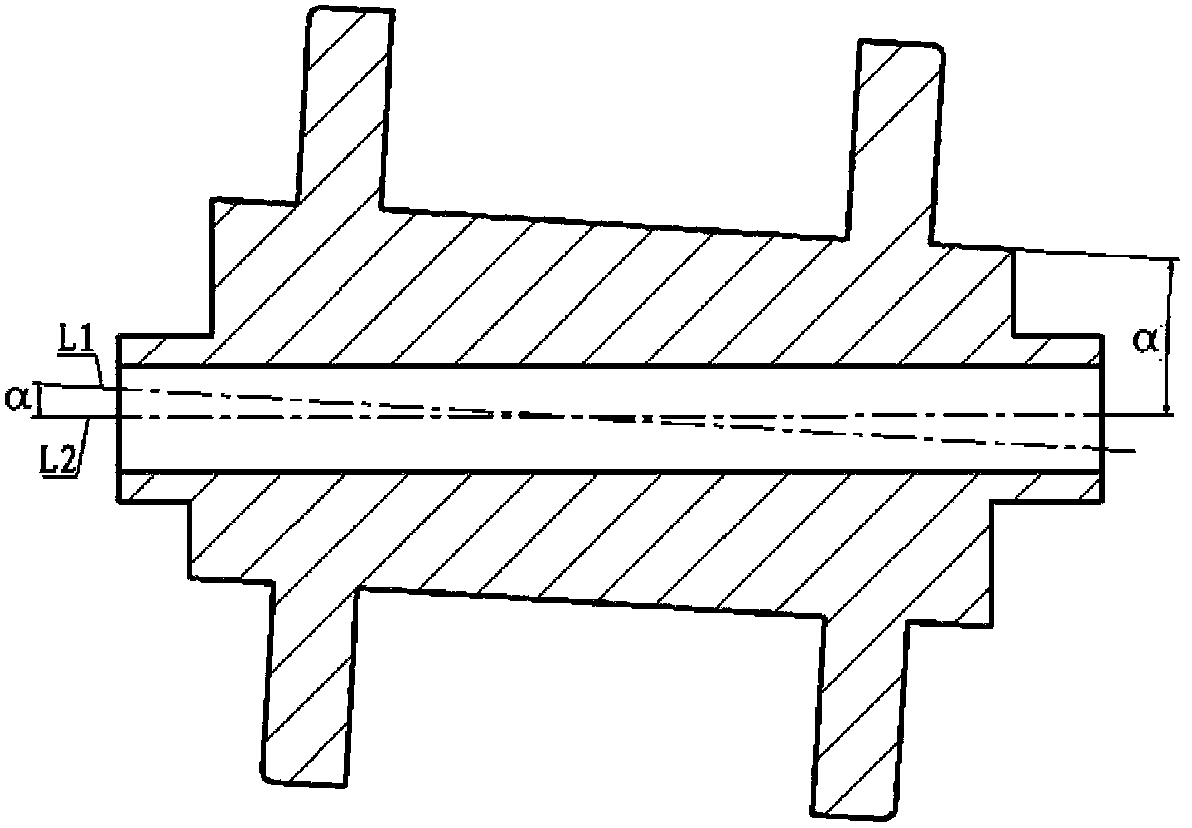

[0023] like figure 1 As shown, the direct drive state extruder screw rotation and axial vibration drive device includes swing drive sleeve 1, thrust roller bearing 2, swing ring 3, linear rolling bearing 4, joint bearing 5, drive motor 6, motor hollow shaft 7. The feeding screw sleeve 8 and the plasticizing transport screw 9; the motor hollow shaft 7 is fixed on the rotor of the driving motor 6, the feeding screw sleeve 8 is a hollow screw rod, and the feeding screw sleeve 8 is fixed on the end cover of the driving motor 6 and Installed in the hollow shaft 7 of the motor, the plasticizing transport screw 9 is installed in the inner hole of the feeding screw sleeve 8; the swing drive sleeve 1 is connected with the hollow shaft 7 of the motor through the linear rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com