Device and method for curing and flattening glue-free soft plate material

A soft board and leveling technology, which is applied in the field of curing and leveling of non-adhesive soft board materials, can solve the problems of lower yield rate, loose surface unevenness, and elongated material length, so as to reduce labor intensity, avoid mutual adhesion, and operate controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

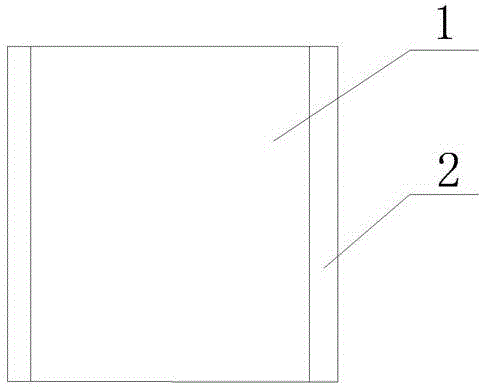

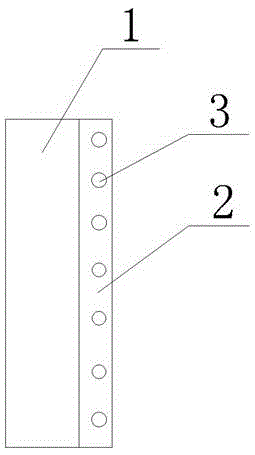

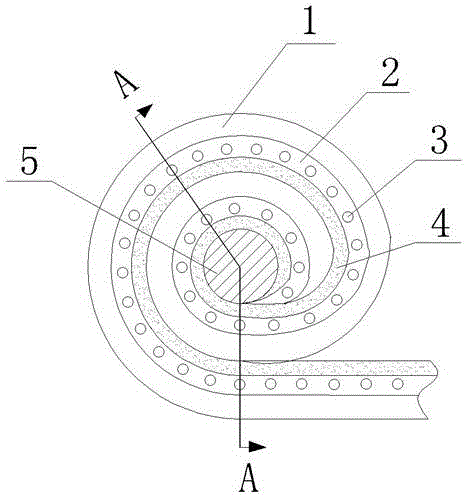

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention discloses a device for curing and flattening glue-free soft board materials, which includes a rewinder and a metal heat conducting plate 1, and steel strips 2 are arranged at both ends of the lower surface of the metal heat conducting plate 1, so that The steel strip 2 is provided with pores 3 . In the production process, the soft plate material 4 is flatly attached to the upper surface of the metal heat conducting plate 1, and then the metal heat conducting plate 1 and the soft plate material 4 are tightly crimped on the steel pipe of the rewinding machine. 5, that is, the soft board material 4 can be cured through the metal heat conducting plate 1. When the metal heat conduction plate 1 and the soft plate material 4 are crimped on the rewinder, the space formed by the metal heat conduction plate 1, the steel strip 2 and the soft plate material 4 passes through the The pores 3 comm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com