Fireproof anti-explosion system of floating-roof oil tank

A floating roof oil tank, explosion-proof system technology, applied in the direction of container, packaging, transportation and packaging, can solve the problems of no application, only theory, no implementation plan, etc., to achieve the effect of simple structure and prevention of fire and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

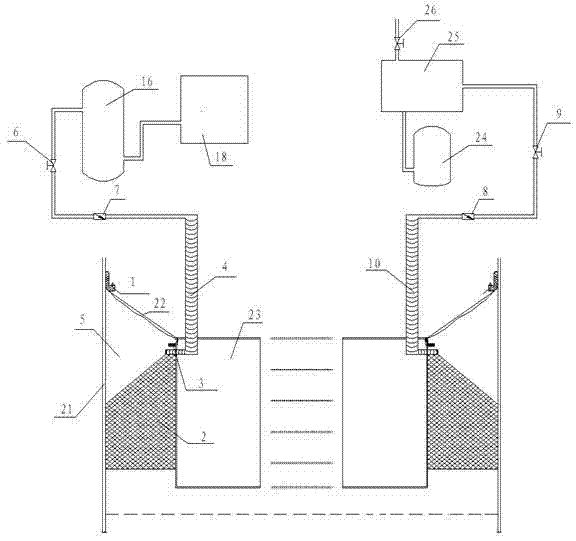

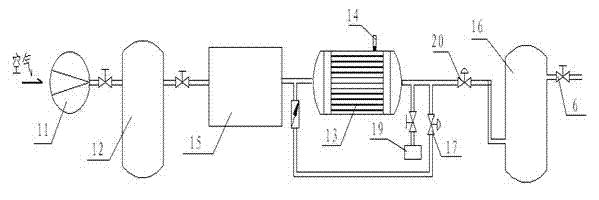

[0016] as attached figure 1 As shown, the floating roof oil tank includes a floating roof tank 23 , an oil tank pipe wall 21 , a bead 22 , a primary seal 2 and a secondary seal 1 . The annular oil-gas space 5 is surrounded by the primary seal 2, the secondary seal 1, the bead 22, the oil tank pipe wall 21, and the floating roof tank 23, and the primary seal 2 and the secondary seal 1 are arranged in the floating roof tank 23 Between the pipe wall 21 and the oil tank, it is used to seal the annular oil-gas space 5 . In the oil-gas space 5, 2-4 oil-gas concentration measuring instruments 3 are uniformly arranged along the circumferential direction to detect the oil-gas concentration in the space in real time.

[0017] Two flexible flexible pipes are installed on the floating roof floating cabin 23, i.e. the nitrogen gas inlet pipe 4 and the mixed gas discharge pipe 10, and the inner ends of the nitrogen gas inlet pipe 4 and the mixed gas outlet pipe 10 all enter the ring throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com