Heat-treatment method of high-chromium wear-resistant white cast iron Cr28

A heat treatment method and technology for white cast iron, which are applied in the field of heat treatment to improve the service life of high-chromium wear-resistant white cast iron Cr28, and achieve the effects of improving service life, service life, hardness and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

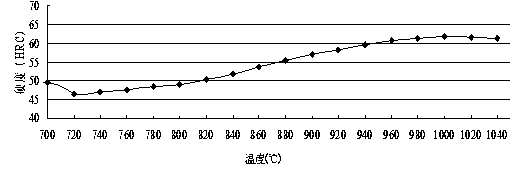

[0022] Quenching: Take high-chromium wear-resistant white cast iron Cr28 and heat it to 1050°C, keep it warm for 1.5h, and air-cool to room temperature;

[0023] High-temperature tempering: heat the quenched cast iron Cr28 to 720°C, keep it warm for 2 hours, and air-cool to room temperature. The obtained cast iron Cr28 has a hardness of 46HRC;

[0024] Secondary quenching: heat cast iron Cr28 to 1050°C, keep it warm for 1.5h, and air cool to room temperature;

[0025] Low temperature tempering: heat cast iron Cr28 after secondary quenching to 500°C, keep it warm for 1.5h, and air cool to room temperature;

[0026] Repeat the low-temperature tempering step to obtain the product.

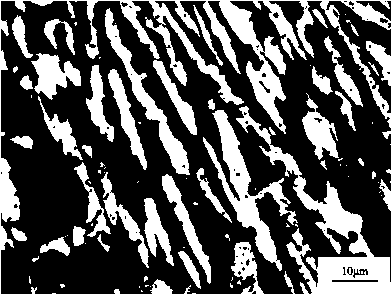

[0027] The hardness of the finally obtained cast iron Cr28 is 61HRC, and the grain structure is refined at the same time, and the wear-resistant hardened particles (carbides) are changed from thick strips to spherical shapes, and the alloy elements in the structure are more uniform. The service ...

Embodiment 2

[0029] Quenching: Take high-chromium wear-resistant white cast iron Cr28 and heat it to 1000 ° C, keep it warm for 3 hours, and air cool to room temperature;

[0030] High-temperature tempering: heat the quenched cast iron Cr28 to 730°C, keep it warm for 1.5h, and air cool to room temperature. The obtained cast iron Cr28 has a hardness of 47HRC.

[0031] Secondary quenching: heat cast iron Cr28 to 1000°C, keep it warm for 3 hours, and air cool to room temperature;

[0032] Low-temperature tempering: heat cast iron Cr28 after secondary quenching to 450°C, keep it warm for 2 hours, and air-cool to room temperature;

[0033] Repeat the low-temperature tempering step to obtain the product.

[0034] The hardness of the final cast iron Cr28 workpiece is 62HRC, and the grain structure is refined. At the same time, the wear-resistant hardened particles (carbides) change from thick strips to spherical shapes, and the alloy elements in the structure are more uniform. The service life ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com