Retroreflection coefficient measurement method adopting spectral correction

A retroreflection coefficient and spectral measurement technology, applied in the measurement of scattering characteristics, etc., can solve problems such as fitting degree and response characteristics, cost constraints, difficulty in perfection, deviation, etc., achieve optimal response characteristics and cost, and reduce system inconsistencies. Determining the degree component, improving the effect of accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

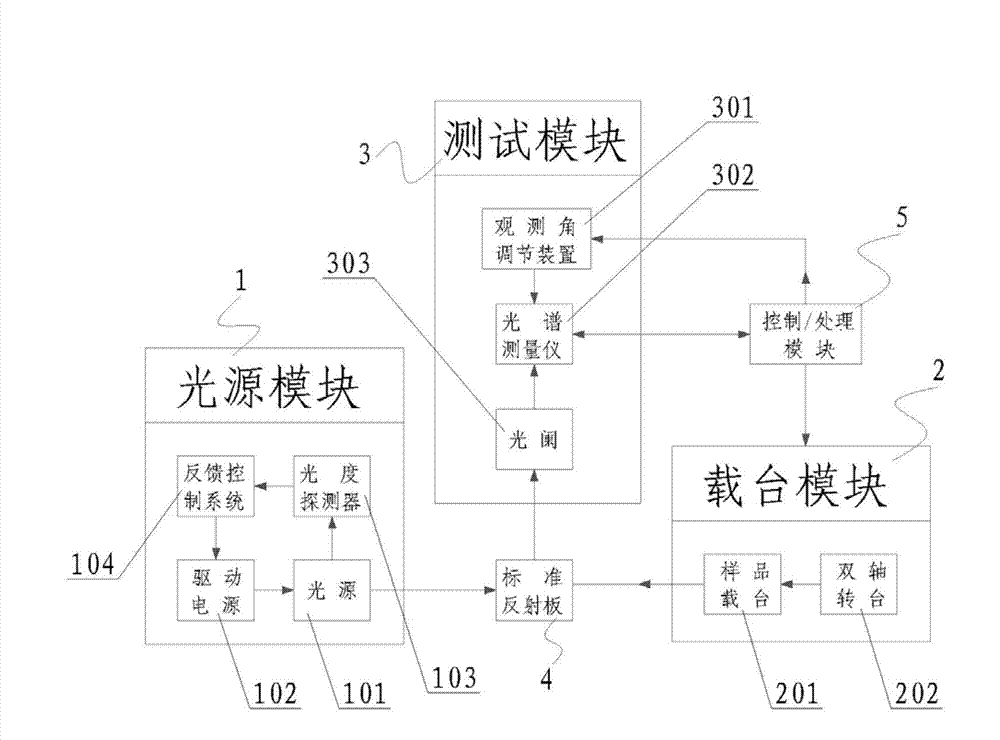

[0034] This embodiment provides a retroreflectance measuring device using spectral correction, see figure 1 , the device includes: a light source module 1, a stage module 2, a test module 3, a standard reflector 4 and a control / processing module 5, the light source module 1 is used to emit a stable visible spectrum, and the spectrum emitted by the light source module 1 is within the range of visible light The domestic requirements cover the spectral range to be studied and tested.

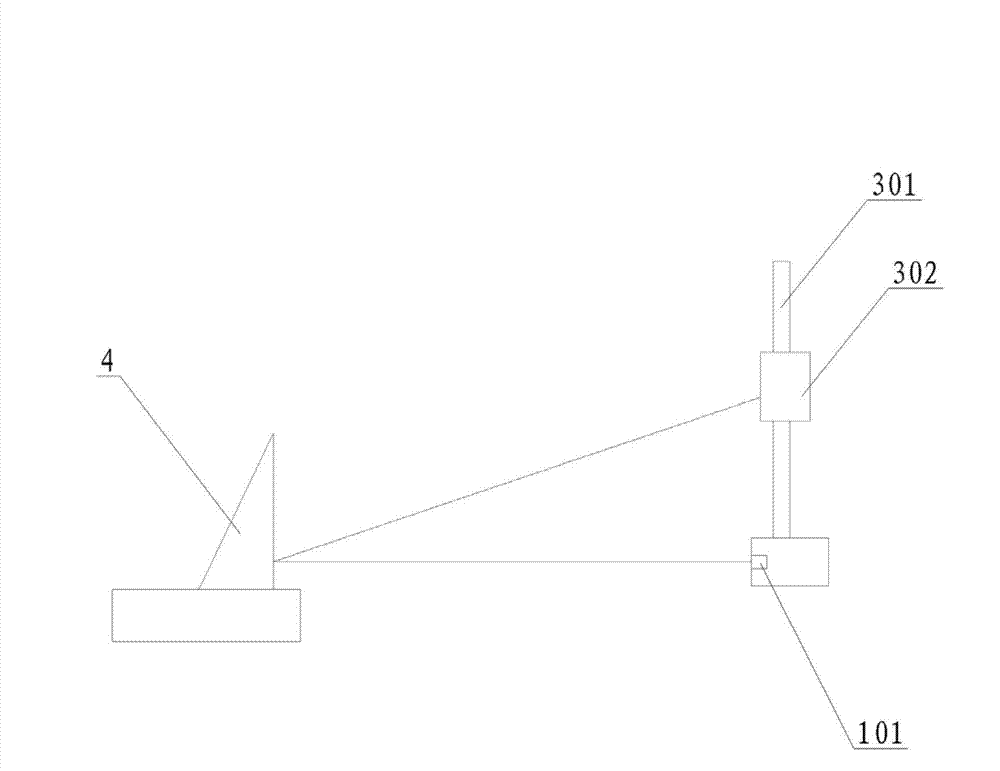

[0035] The light source module 1 and the carrier module 2 are arranged facing each other, the standard reflector 4 is arranged on the carrier module 2, the test module 3 and the light source module 1 are arranged on the same side of the carrier module 2, preferably, the test module 3 is arranged Above the light source module 1, and the angle of the carrier module 2 can be adjusted. In this way, the spectrum emitted by the light source module 1 can be irradiated flatly onto the standard reflector 4...

Embodiment 2

[0038] This embodiment provides a retroreflectance measuring device using spectral correction, see figure 1 with figure 2 , the device includes: a light source module 1, a stage module 2, a test module 3, a standard reflector 4 and a control / processing module 5, the light source module 1 is used to emit a stable visible spectrum, and the spectrum emitted by the light source module 1 is within the range of visible light The domestic requirements cover the spectral range to be studied and tested. The light source module 1 and the carrier module 2 are arranged facing each other, the standard reflector 4 is arranged on the carrier module 2, the test module 3 and the light source module 1 are arranged on the same side of the carrier module 2, preferably, the test module 3 is arranged Above the light source module 1, and the angle of the carrier module 2 can be adjusted. In this way, the spectrum emitted by the light source module 1 can be irradiated flatly onto the standard refl...

Embodiment 3

[0043] The present invention provides a method for measuring retroreflection coefficient using spectral correction, using the device provided by the above-mentioned embodiment, the measuring method includes:

[0044] S1, fix the standard reflector 4 on the sample carrier 201, turn on the measuring device, and adjust the geometric conditions of the optical path system to meet the assignment requirements of the standard reflector 4;

[0045] S2, under the condition that the light source 101 stably outputs the preset luminous intensity, obtain the relative radiation intensity spectral distribution of the reflected light of the standard reflector 4 through the test of the spectrometer 302;

[0046] S3, using software to correct the human eye photopic function V(λ) to obtain the relative luminous intensity spectral distribution of the reflected light of the standard reflector 4 at a certain geometric test angle;

[0047] Substitute the product of the preset output luminous intensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com