Detection disc in metal detector

A technology of metal detectors and detection coils, which is applied in the field of metal detectors, can solve the problems of expanding production occupation space, affecting production efficiency, poor consistency of detection coils, etc., and achieves the effect of good batch production consistency and pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

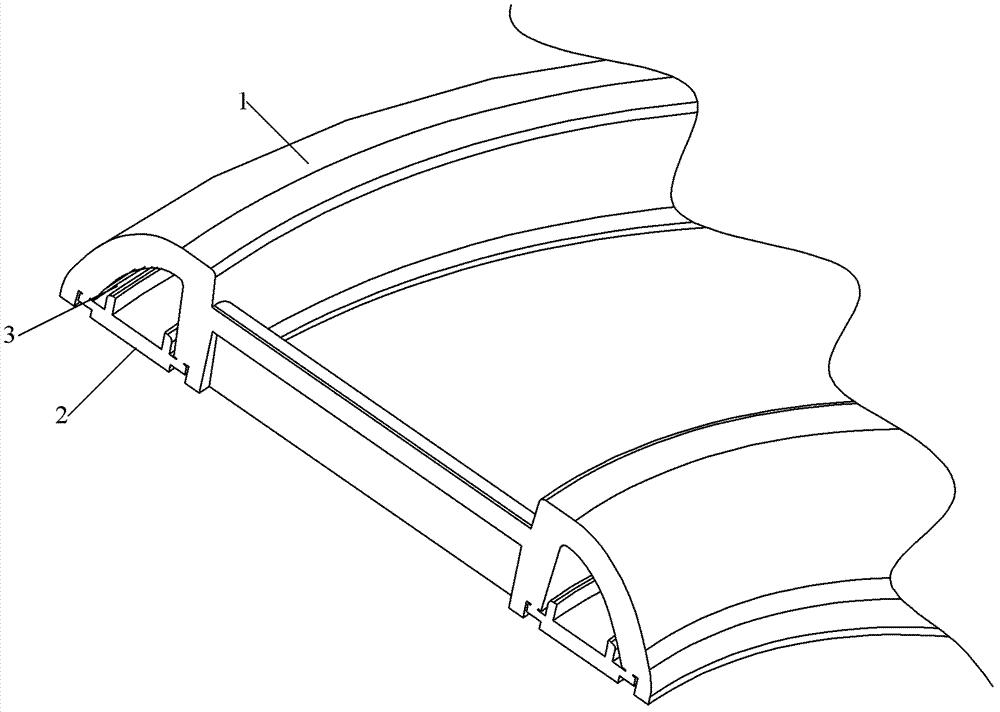

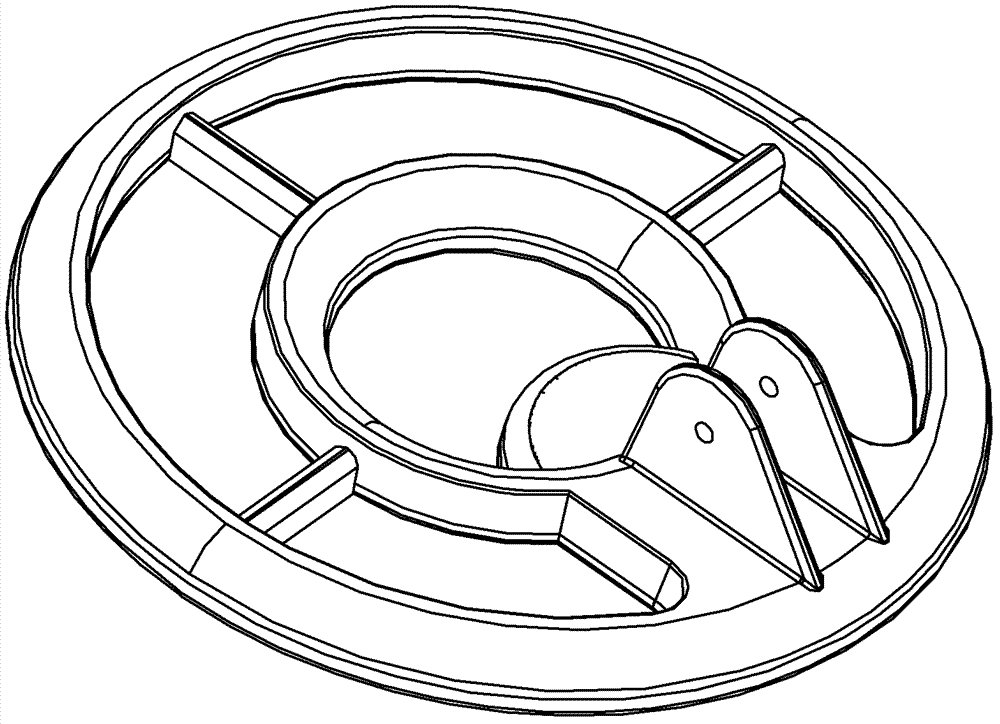

[0010] Such as figure 1 and figure 2 As shown, the detection disk in the metal detector of the present invention includes a disk cover 1, a disk bottom 2 and a hot-melt strip 3, and the disk cover 1 is fixed to the bottom 2 of the disk by the hot-melt strip 3, and the disk cover is specifically bonded by means of ultrasonic thermal fusion. It resonates with the bottom of the pan under the action of ultrasonic waves. The function of the hot-melt strip is to generate heat during the resonance and be in a molten state. After pressurization, the pan cover and the bottom of the pan are integrated. The shape of the hot-melt strip is an isosceles triangle, and the sharp part of the triangle is the place where the ultrasonic wave starts to vibrate.

[0011] The invention uses an ultrasonic hot-melt machine to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com