Grounding wire safety operation device in power construction

A technology for safe operation and electrical construction, applied in the direction of electrical connection seat, clip connection conductor connection, etc., can solve problems such as delayed operation time, insufficient clamping of wire clips, and inability to hang ground wires, so as to reduce labor intensity and ensure personal safety. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

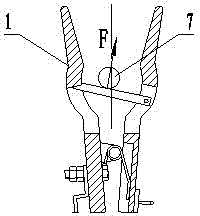

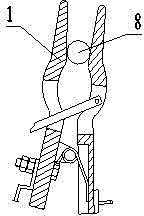

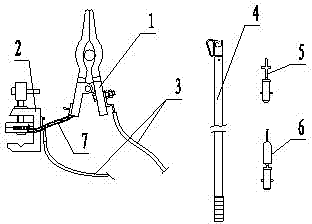

[0022] see image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , the present invention includes a grounding fixture 2, a wire clamp 1, a ring chain pin 7, a copper strand 3, an operating rod 4, a cross connector 5 and an electroscope 6, and the grounding fixture 2 and the conductor clamp 1 Connected by copper stranded wire 3, the ring chain of the ring chain bayonet 7 is fixed on the tail of the wire clamp 1, and the bayonet of the ring chain bayonet is matched with the grounding clamp 2; wherein, the wire clip 1 is a striker Type wire clamp, the internal striker of the striker type clamp is a folded hinge structure striker, which includes striker I1-1 and striker II1-2, one end of the striker I1-1 is hinged on the right side of the wire clamp 1, and the other One end is hinged with the head of the striker II 1-2, and the tail of the striker II 1-2 is provided with a card slot matching the left clamp body of the wire clamp 1; lining boards 1- are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com