Picking actuating mechanism used at tail end of pineapple picking mechanical arm

A technology of robotic arms and actuators, applied in the field of harvesting actuators, which can solve problems such as the long distance between the fruit clamping center and the arm fixing plate, the large structural size of the gripper, and the large overall quality, so as to reduce the power consumption of picking and have a simple structure Compactness, the effect of improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

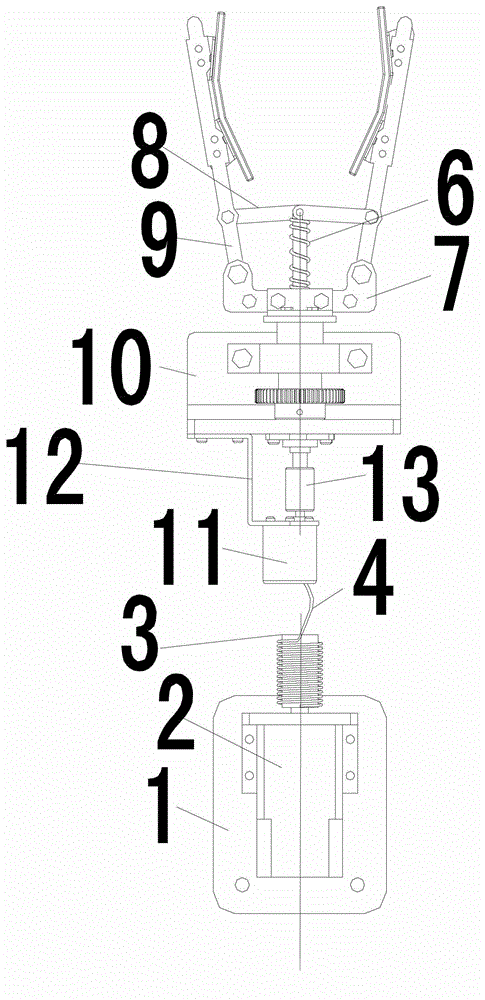

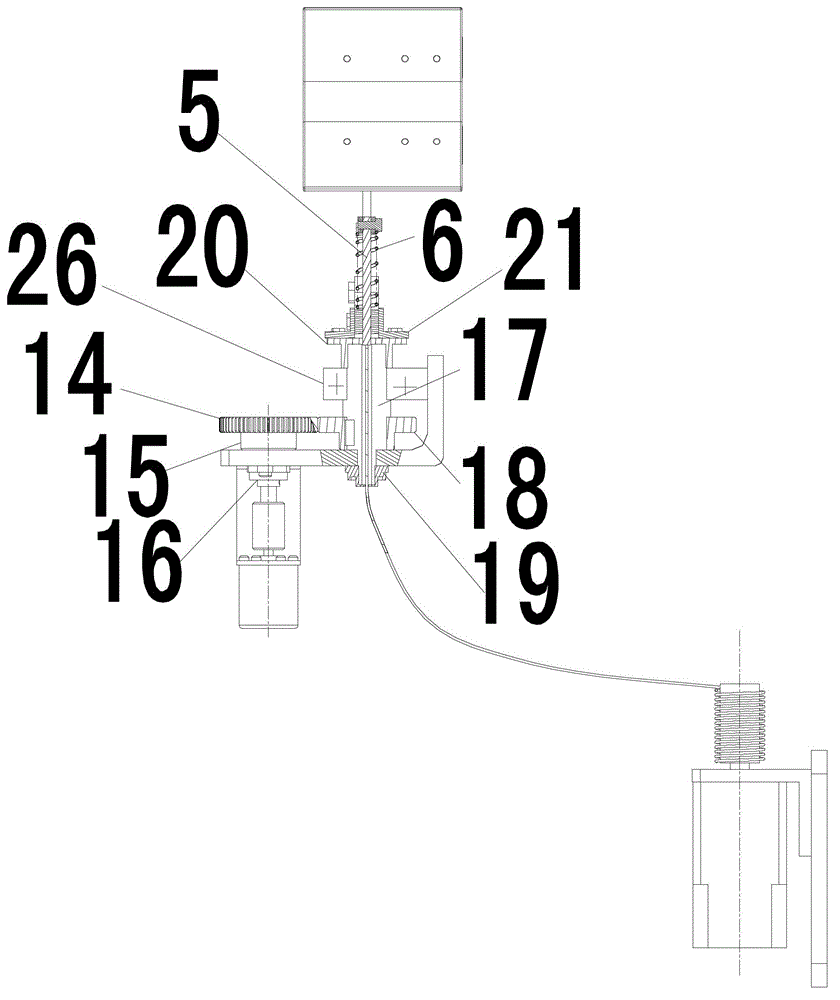

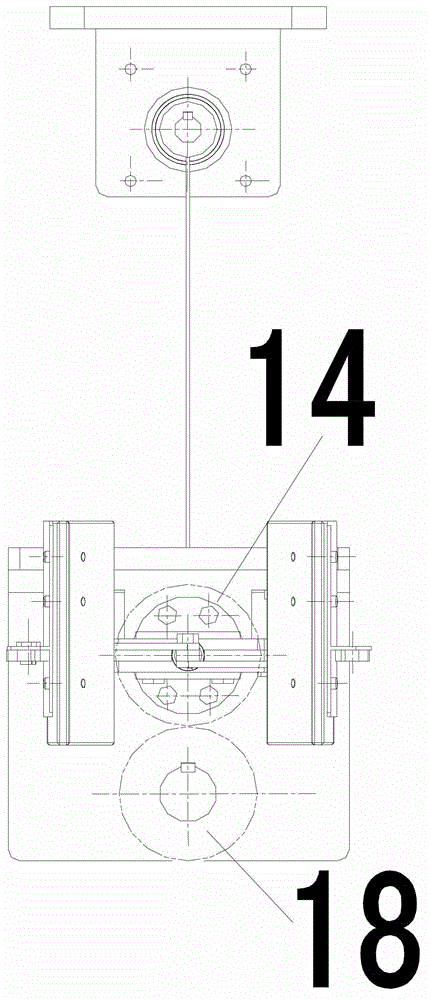

[0031] like Figures 1~4 As shown, a picking execution device for the end of a pineapple picking robotic arm includes a clamping mechanism for clamping the pineapple, a torsional separation mechanism for twisting and separating the pineapple, and a clamping mechanism and a twisting separation mechanism for fixing the clamping mechanism and the torsion separation mechanism. Connected flange assembly.

[0032] The clamping mechanism in this embodiment includes a frame connecting plate 1, a clamping motor 2, a reel 3, a wire rope 4, a pull rod 5, a spring 6, a gripper support plate 7, two cross bars 8 and two grippers 9; wherein, the frame connecting plate 1 is fixedly connected to the picking robot frame, the clamping motor 2 is fixedly installed on the frame connecting plate 1, the wire reel 3 is fixedly installed on the output shaft of the clamping motor 2, and the wire reel 3 A steel wire rope 4 is wound on it, the extension end of the wire rope 4 is fixedly connected with o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com