Spray dust collector

A dust collector and dust technology, applied in the direction of suction filter, etc., can solve the problems of increased wind resistance, affecting physical and mental health, and generating noise, etc., to achieve low working noise, prevent disturbance, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

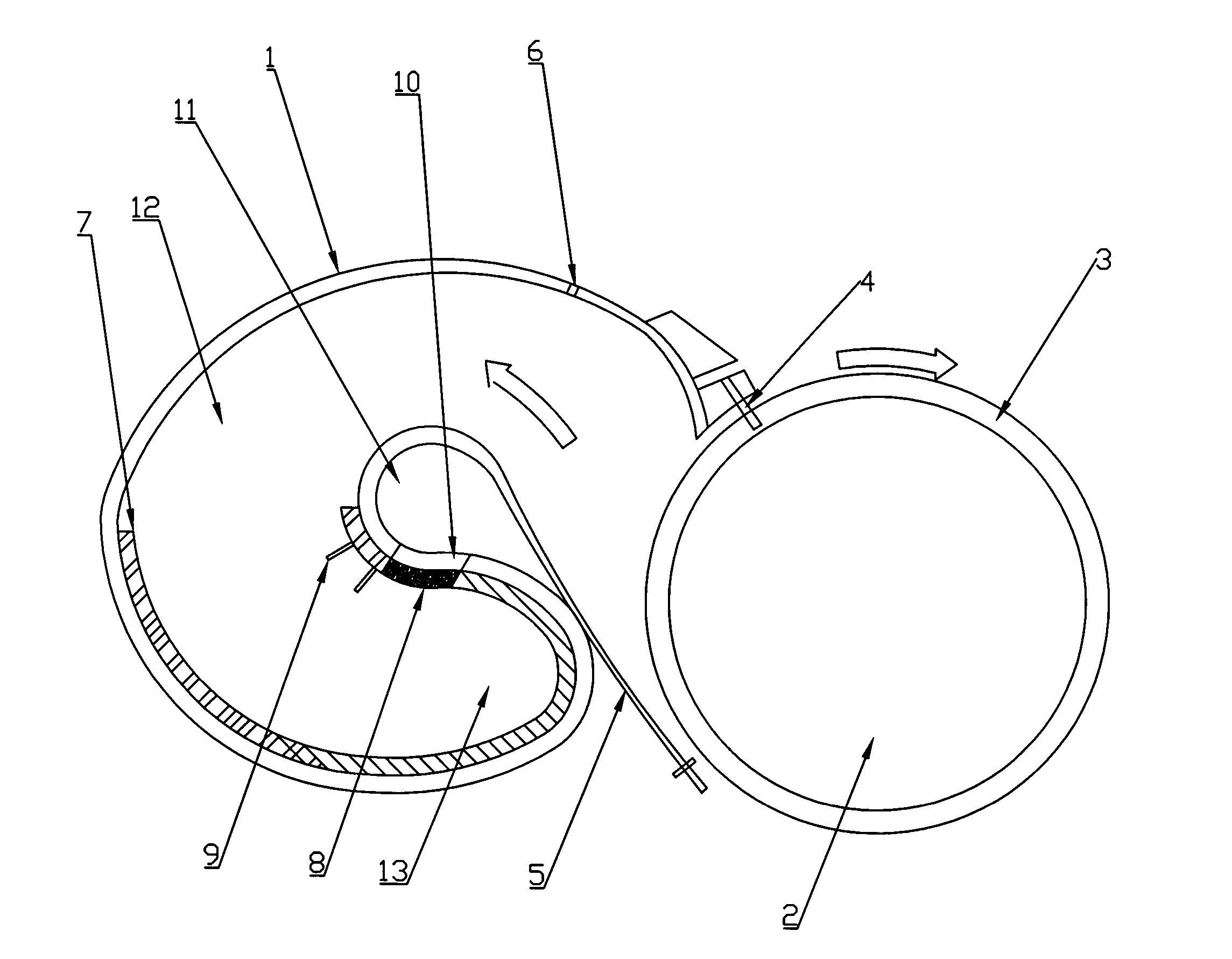

[0010] As shown in the figure, the spray dust collector consists of dust collection chamber 1, roller 2, nylon brush 3, guide rod A4, guide rod B5, steam injection port 6, inner tank 7, stainless steel filter screen 8, damper 9, ventilation Port 10 and exhaust pipe 11; steam injection port 6 is set at the entrance of dust collection chamber 1, guide rod A4 and guide rod B5 are respectively arranged above and below the entrance of dust collection chamber 1, and guide rod B5 is surrounded by dust collection chamber 1 in a row A nylon brush 3 is provided on the outer circle of the air pipe 11 and the roller 2, and the guide rod A4 is in contact with the nylon brush 3; the dust collection chamber 1 is composed of a condensation area 12 and a drainage area 13, and the condensation area 12 adopts a circular involute structure, The drainage area 13 adopts a Fermat spiral structure, the inner wall of the drainage area 13 is provided with a liner 7, the top of the drainage area 13 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com