A gaseous nitrous acid generating device and its process

A technology of gaseous nitrous acid and generating device, applied in the direction of nitrous acid, nitrogen oxides/oxyacids, etc., can solve the relatively high requirements of control and sealing, consumption and replacement of gas stability interference, repeatability and stability Not ideal and other problems, to achieve the effect of good practical value, good purity and stability, simple and reliable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

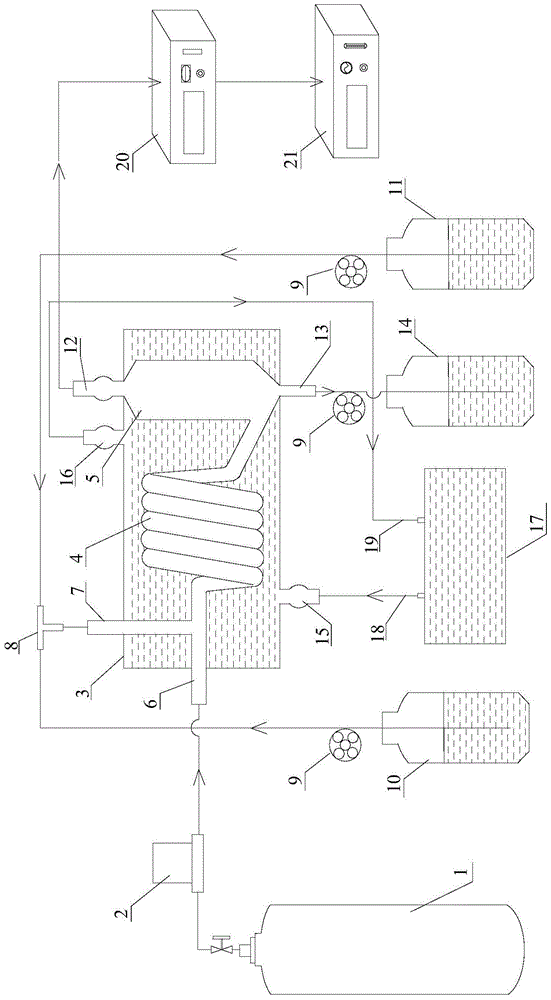

[0030] The gaseous nitrous acid generating device of the present invention, as figure 1 As shown, it includes a mass flow controller 2 connected to a compressed steel cylinder 1 and a gas delivery pipeline. The output end of the mass flow controller 2 is connected to a spiral tube gas generator 3, and the spiral tube gas generator 3 is input by gas The tube 6 is connected to the integrally formed glass spiral tube 4 and the gas-liquid separation bottle 5 in sequence. On the gas input line 6 of the glass spiral tube 4, a bypass input tube 7 is formed, and the bypass input tube 7 is connected through a three-way valve. 8 and the infusion pipeline at the two ends of the three-way valve 8 and the peristaltic pump 9 are respectively connected to the dilute sulfuric acid reagent bottle 10 and the sodium nitrite solution reagent bottle 11; the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com