Compression roller for biomass granulator

A granulator and biomass technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of easy damage of parts, high friction pressure of rollers, eccentric shaft, easy damage of bearings, etc., to prevent damage and reduce friction pressure Effect

Inactive Publication Date: 2013-02-06

LIYANG ZHENYANG MACHINERY PLANT

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its main disadvantages: when the biomass is granulated, the friction pressure of the pressure roller provided is too high, and the internal parts of the ring die granulator are easily damaged, such as: the eccentric shaft, the bearing, etc. are easily damaged

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

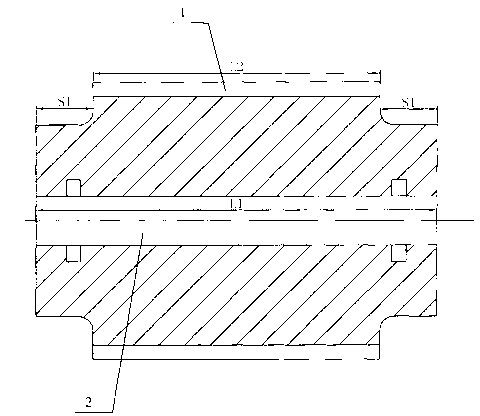

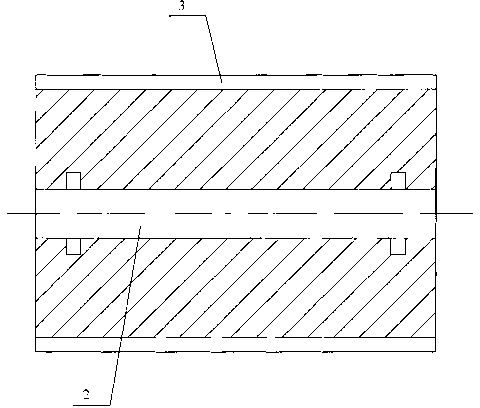

[0017] like figure 1 As shown, a pressing roller for a biomass granulator includes: a working surface A1 of the pressing roller and a center hole 2 of the pressing roller, where 0

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a compression roller for a granulator, in particular to the compression roller for a biomass granulator, and belongs to specialized rolling units for a hoop standard granulator. The technical scheme includes that the compression roller for the biomass granulator comprises a working surface A (1) and a central hole (2), wherein the length L2 of the working surface A (1) is larger than zero and smaller than the length L1 of the central hole (2). By above technical scheme, the compression roller has the advantage that friction pressure to the working surface of the compression roller is reduced, requirements for internal parts of the biomass granulator are lowered, the internal parts of the biomass granulator are prevented from damage, and service life of the biomass granulator is prolonged.

Description

technical field [0001] The invention relates to a pressure roller for a granulator, in particular to a pressure roller for a biomass ring die granulator, which belongs to the rolling part of the ring die granulator. Background technique [0002] The working principle of the ring die granulator is that the crushed material after quenching and tempering is evenly fed into the pressing space in the ring die through the chute through the die cover, with the help of gravity, the centrifugal force generated by the rotation of the ring die and the action of the feeding scraper. . Under the strong extrusion of the ring die and the pressure roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole. Since the extrusion of the material between the die rollers is continuous, the formed The final material is continuously discharged from the die hole in a columnar shape, and then cut into particles of required length by a cutter. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J2/22

Inventor 杨永君

Owner LIYANG ZHENYANG MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com