Well servicing fluid containing compressed hydrocarbon gas

A carrier fluid, well workover technology, applied in the direction of production fluid, wellbore/well components, drilling composition, etc., can solve the problems of well production reduction, hydrocarbon permeability reduction, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

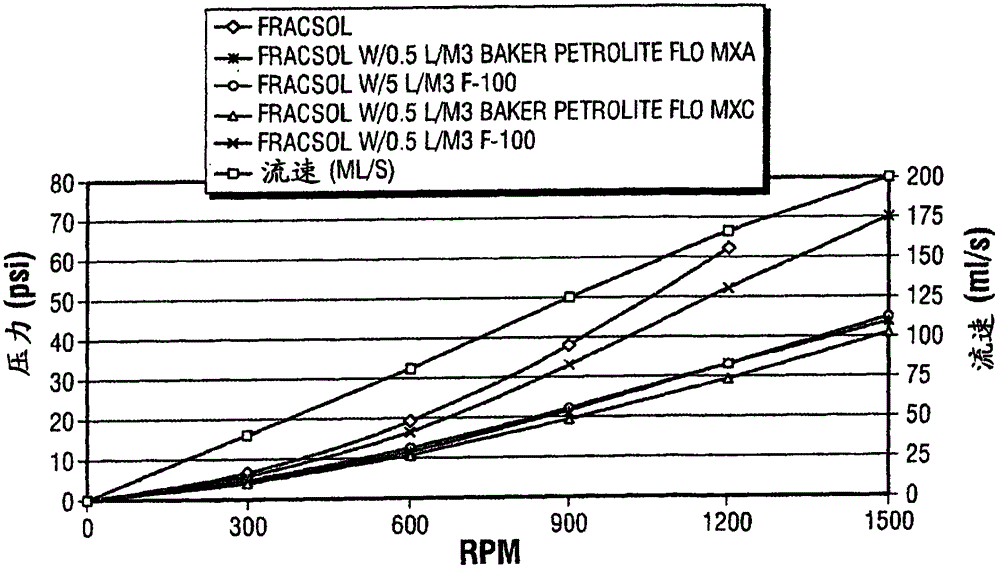

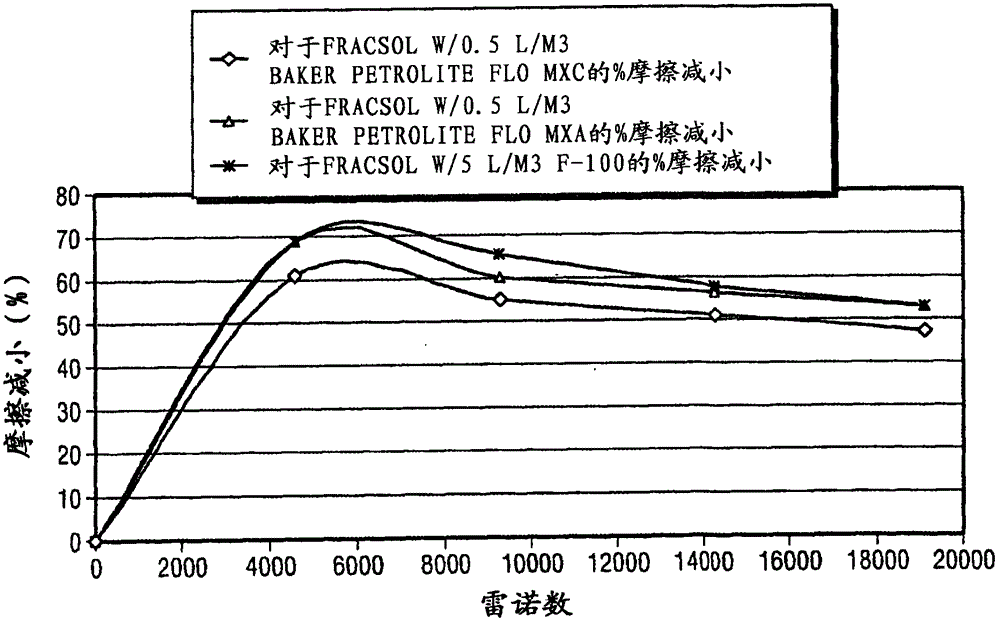

[0050] The above compositions were tested using a friction loop tester. The tester consisted of a 10 foot long, 1 / 4 inch outer diameter and 0.173 inch inner tube fitted with a manometer to measure frictional pressure. A triplex pump connected to the inlet was used to pump fluid from the 4 L container into the 1 / 4 inch tubing through the inlet. The 1 / 4 inch tubing was set so that fluid flowed from the tubing into an inverted altar with 1 inch ID coiled tubing to reduce fluid velocity. The drain from the altar was returned to the 4L container to complete the circuit. A site glass is provided to observe fluid flow through the tester.

[0051] Using the Friction Loop Tester described above, the following general procedure was followed: Pour 4L of FRACSOL into a 4L container. The pump was turned on and fluid was circulated through the friction loop until no air bubbles were observed in the field glass. Take baseline friction pressure readings for the FRACSOL at 300-1500 rpm. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com