Low-mass flow rate perpendicular water cooled wall arrangement method

A layout method and water-cooled wall technology, applied in the direction of boiler water pipes, etc., can solve the problem of mismatched distribution of heat absorption and heat flow density, and achieve the effects of reasonable distribution, reduced friction and pressure drop, and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principle, specific structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

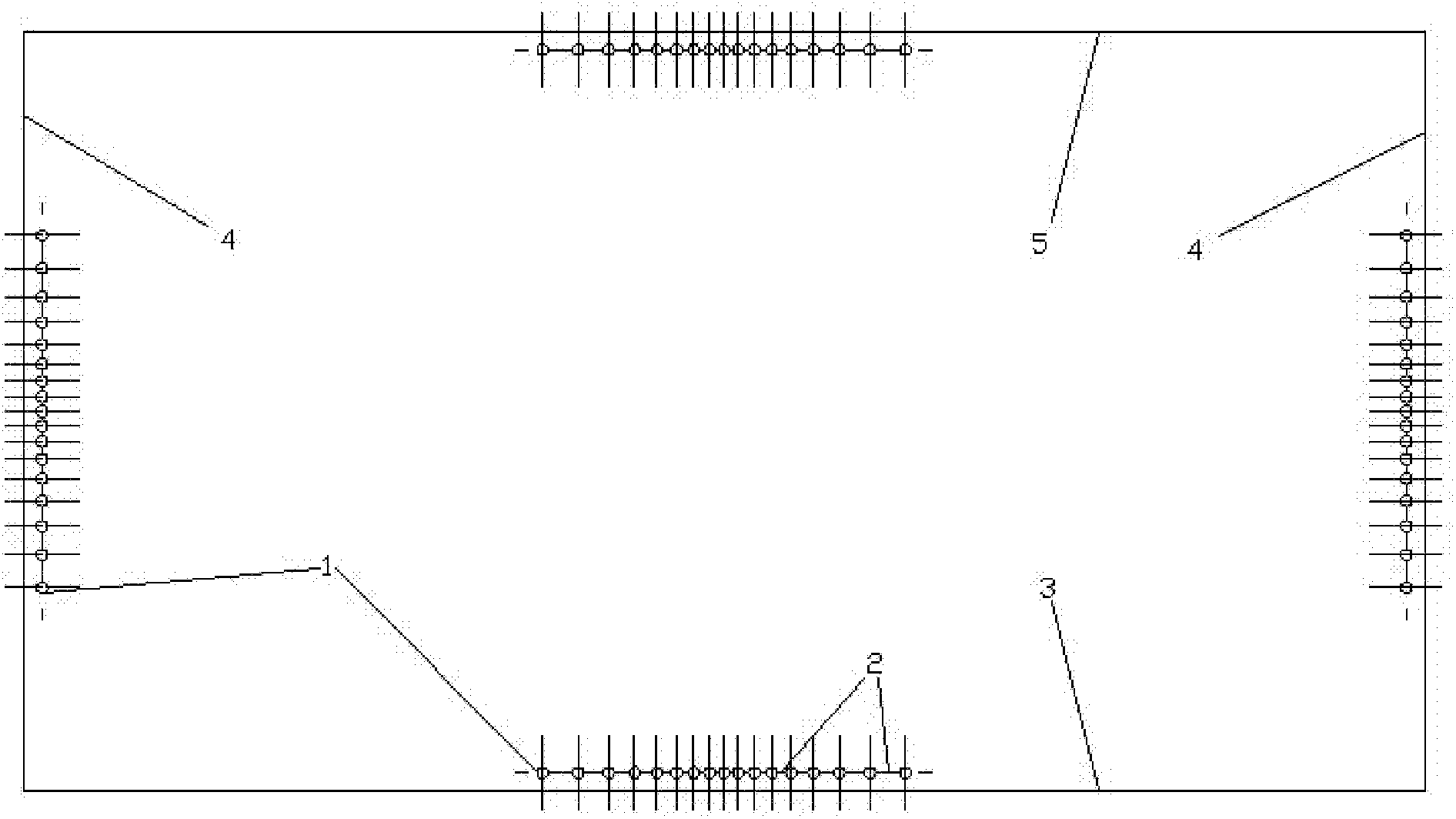

[0014] figure 1 It is a schematic diagram of a low mass flow rate vertical water wall arrangement method. It mainly includes a vertical water wall 1 and non-equal-pitch fins 2 . The working fluid enters the water wall from the feed water header of the water wall, heats up in the vertical water wall 1 and absorbs heat, and then is sent to the outlet header of the water wall. In this method, the riser tubes of the water-cooled wall adopt a vertical layout as a whole, and are arranged at non-equal intervals. The space between the riser tubes in the two sides of the low heat flux range of the furnace is relatively large, and the distance between the riser tubes in the middle area of the furnace high heat flux range is relatively small. Small; the distance between each tube is inversely proportional to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com