Manufacturing technique of automobile skylight frame

A technology for automobile sunroofs and manufacturing processes, applied in vehicle parts, roofs, transportation and packaging, etc., can solve the problems of low effective utilization rate of metal sheets, low utilization rate of raw materials, and low manufacturing efficiency, saving machines and labor. Quantity, efficient manufacturing, the effect of high manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

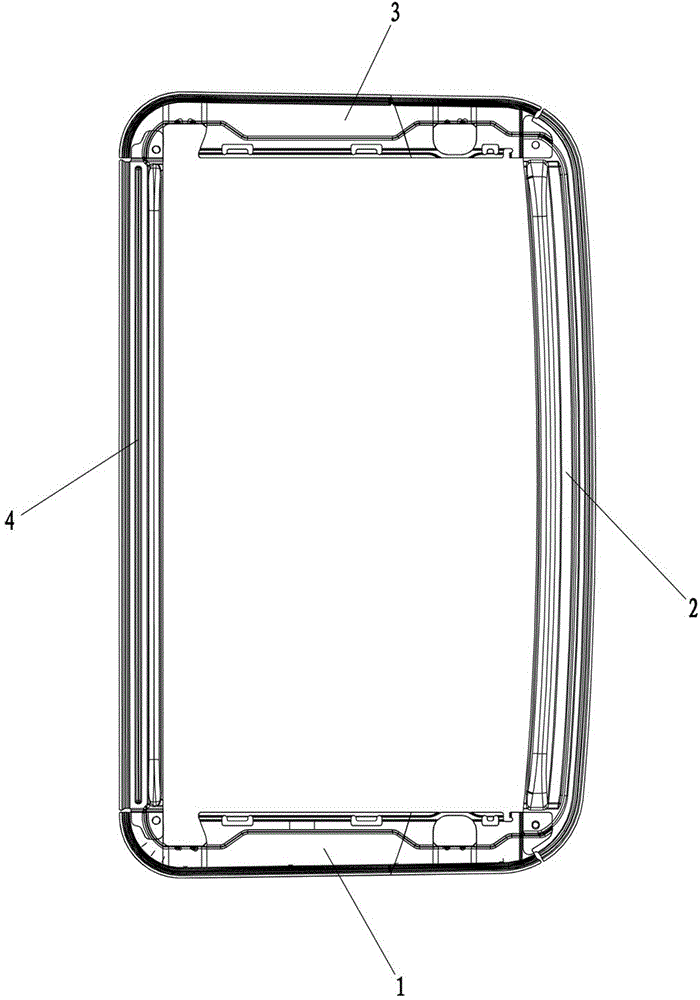

[0014] see figure 1 , a kind of automobile sunroof frame manufacturing process of the present invention, comprises the following steps:

[0015] 1. Simultaneously manufacture single-piece 1 and single-piece 3 on opposite sides of the automobile sunroof frame through progressive die A;

[0016] 2. Simultaneously manufacture the single piece 2 and the single piece 4 of the opposite sides of the automobile sunroof frame through the progressive die B;

[0017] 3. Fix the single piece 1, single piece 2, single piece 3, and single piece 4 manufactured in step 1 and step 2 on the workbench of the automatic welding equipment. At this time, single piece 1, single piece 2, single piece 3, single piece Pieces 4 form a complete car sunroof frame;

[0018] 4. Weld single piece 1 and single piece 2, single piece 2 and single piece 3, single piece 3 and single piece 4, singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com