The train hoisting room of the two-storey storage warehouse for underground and urban railway trains

A train and double-deck technology, applied in the field of subway train manufacturing and maintenance sites and equipment, can solve problems such as complex demolition factors, achieve the effect of saving land area and improving urban traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

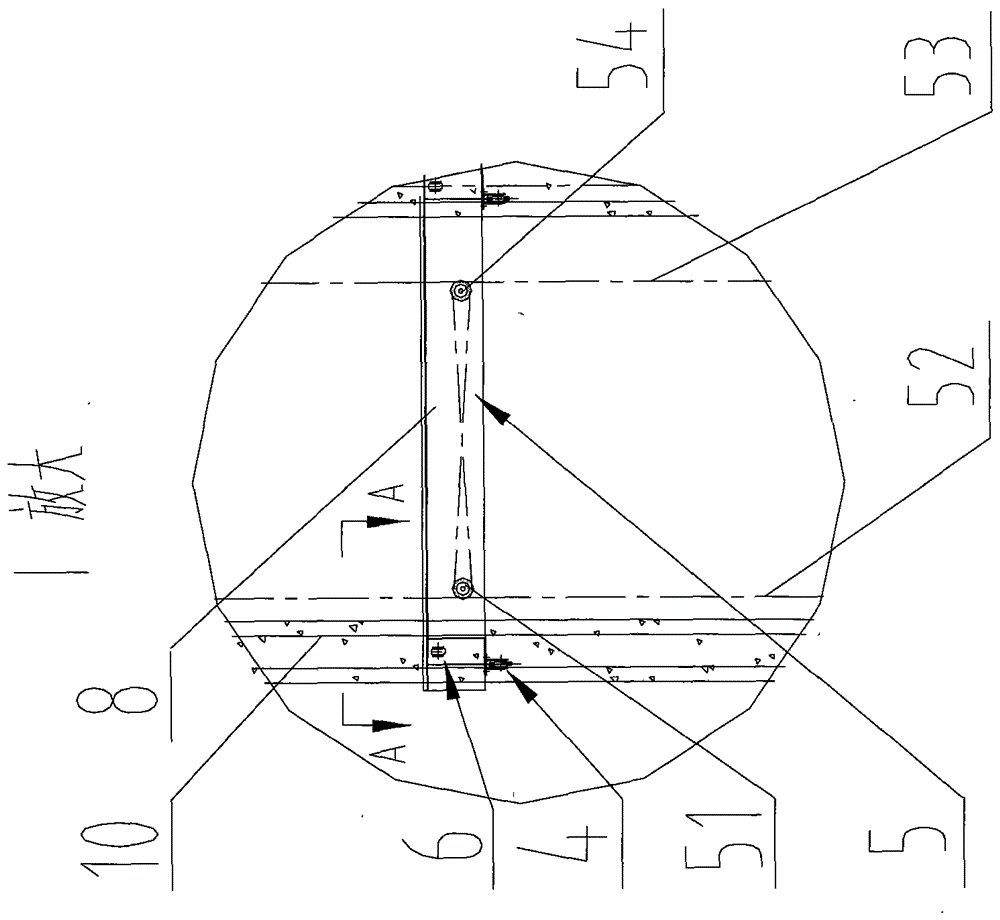

[0033] Embodiments of the present invention are described in conjunction with the accompanying drawings: (all parts with the same structure in the present invention only use one of them to illustrate its structure, and the rest will not be described again, and no reference numerals will be added).

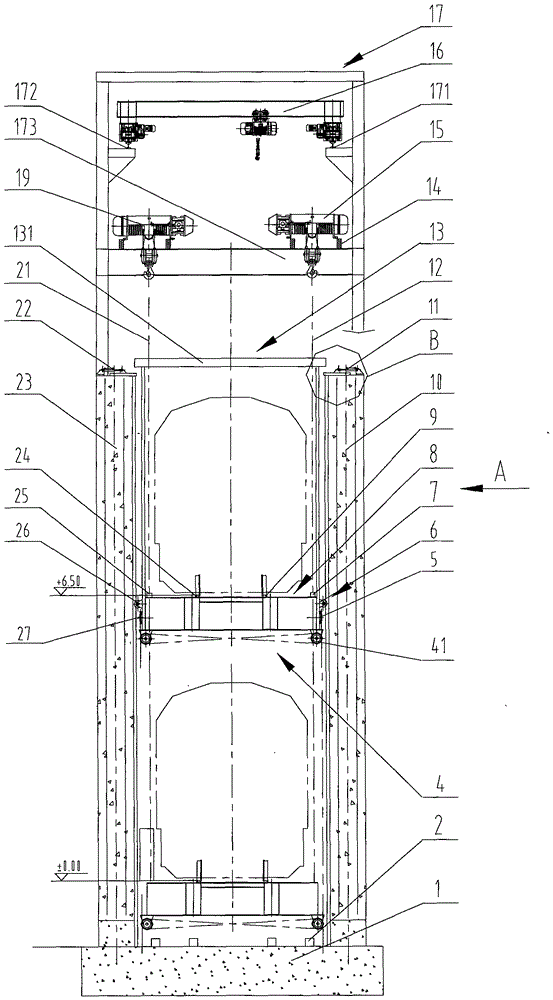

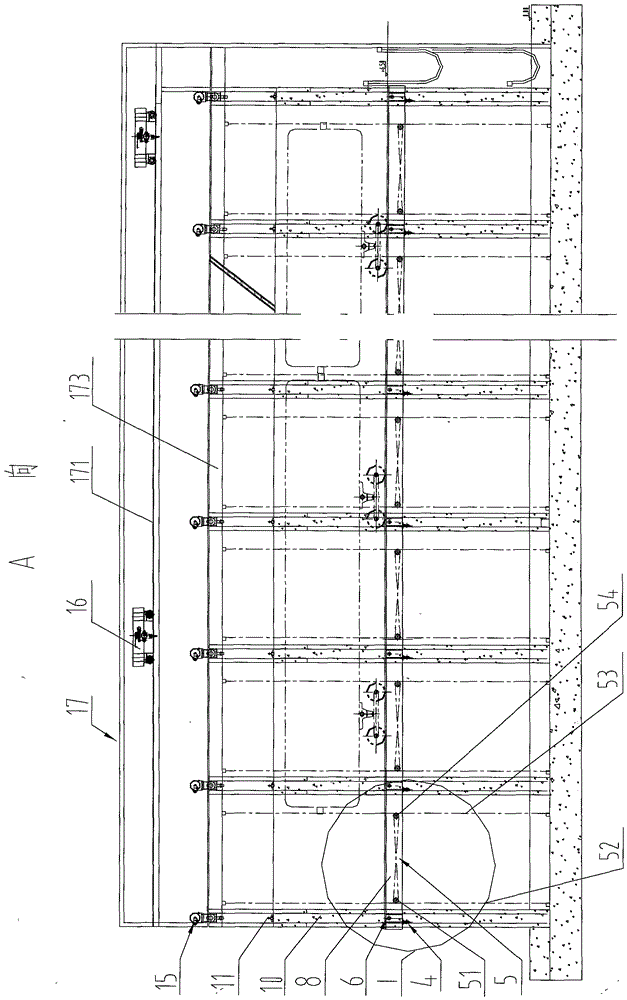

[0034] attached figure 1 , 2

[0035] The present invention welds the steel frame 17 on the embedded parts of 23 left reinforced concrete columns 23 on the left side and 23 right reinforced concrete columns 10 tops on the right, installs the left fixing device 22 and the right fixing device 11, and installs the left fixing device 22 and the right fixing device 11 on the left reinforced concrete column Between 23 and the right reinforced concrete column 10 is a hanger assembly 13, and the hanger assembly 13 is contained on the car platform 8, and the buffer assembly 2 is installed on the concrete ground 1 below the car platform 8.

[0036] The left side rail 172 and the right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com