Metering pump

A technology for metering pumps and pump motors, applied to pumps, pump control, pump devices, etc., can solve the problems of restricting the popularization and use of metering pumps, the inability to achieve metering, and complex structures, etc. Accurate effect of liquid metering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

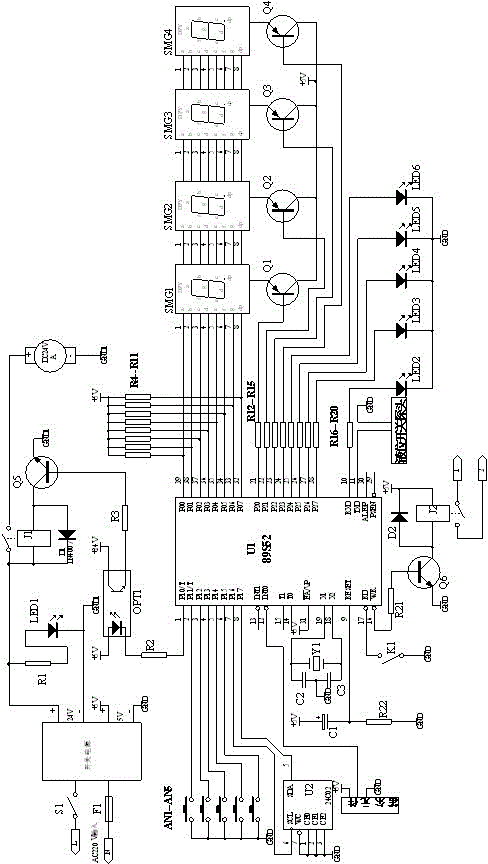

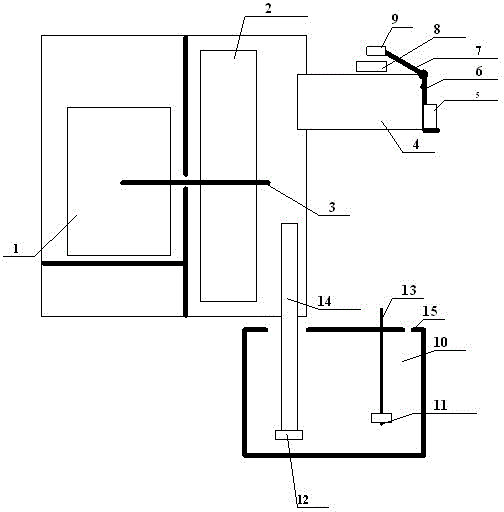

[0015] Such as figure 1 as shown, figure 2 As shown, a metering pump of the present invention includes a pump motor 1 and a control unit, the pump motor 1 is connected to an impeller shaft 3, an impeller 2 is arranged on the impeller shaft 3, and a liquid inlet and a liquid outlet are arranged in the working chamber of the pump motor 1 Port 4, the liquid outlet 4 is provided with a row cover 7, the row cover 7 is provided with a vent hole 6, the lower end of the row cover 7 is provided with a pressing block 5, and the liquid inlet end is passed through the liquid inlet The pipeline 14 is connected with a feeding box 10 , a check valve 12 is provided at the liquid inlet of the liquid inlet pipeline, and the feeding box 10 is provided with a feeding port 15 . The liquid outlet 4 is provided with a row cover detection device, and the row cover detection device is a magnetic steel 9 and a Hall sensor 8, and the magnetic steel 9 is arranged on the row cover 7, and the Hall sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com