Friction plate with a paper friction lining, method for producing such a friction plate and wet-running multiplate clutch or brake comprising such a friction plate

A technology of friction lining and friction plate, applied in a field for producing such friction, to achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

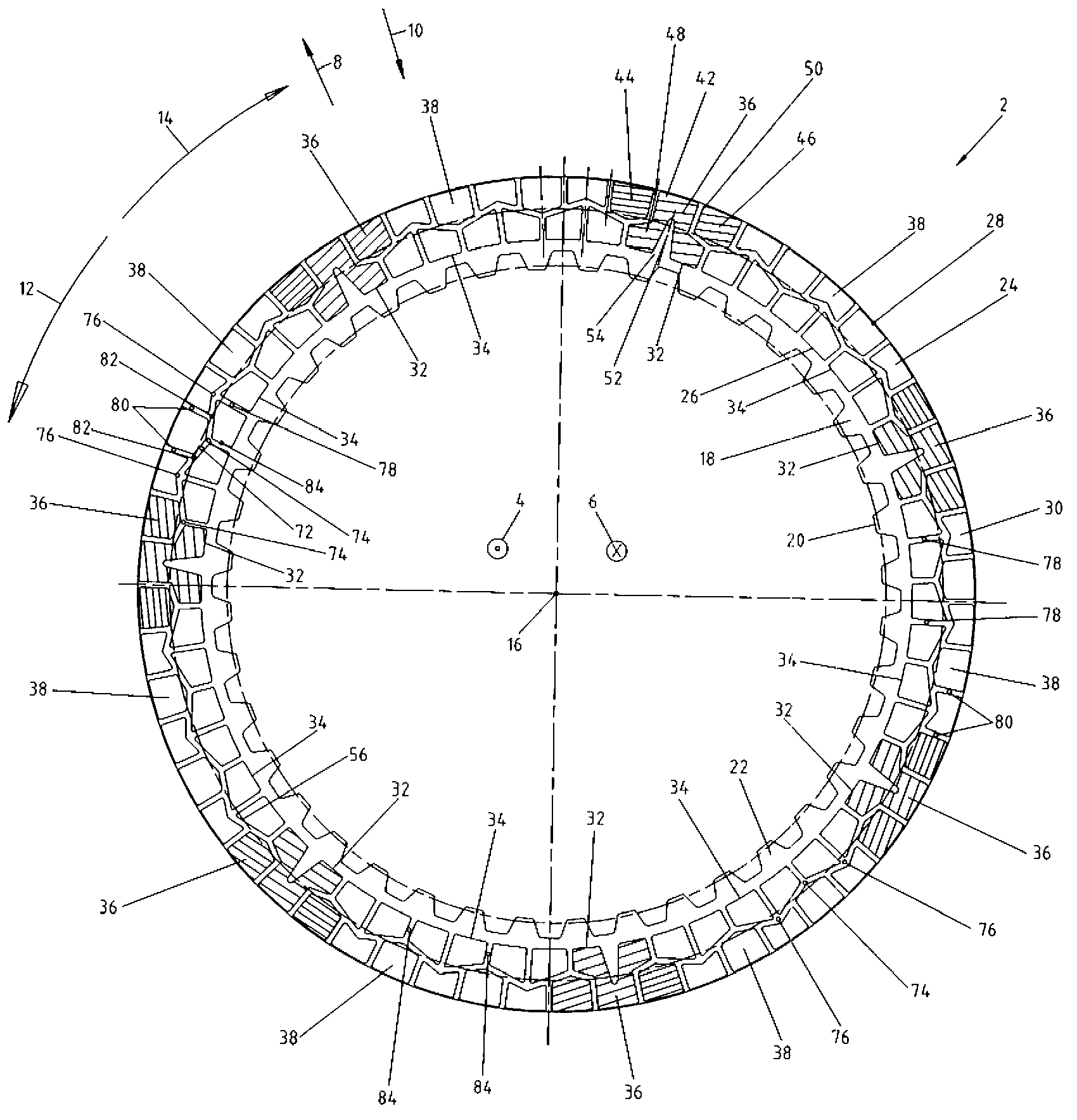

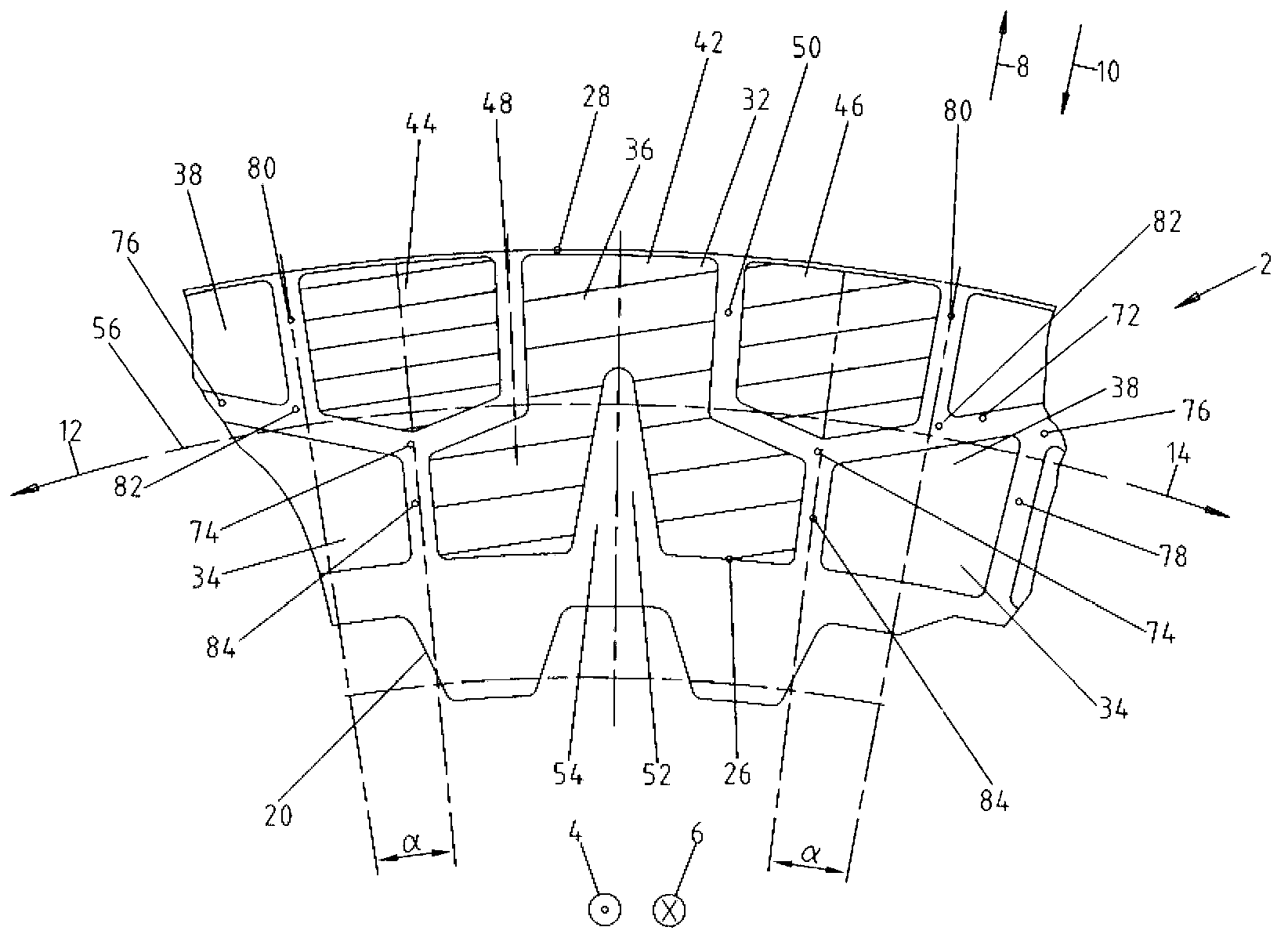

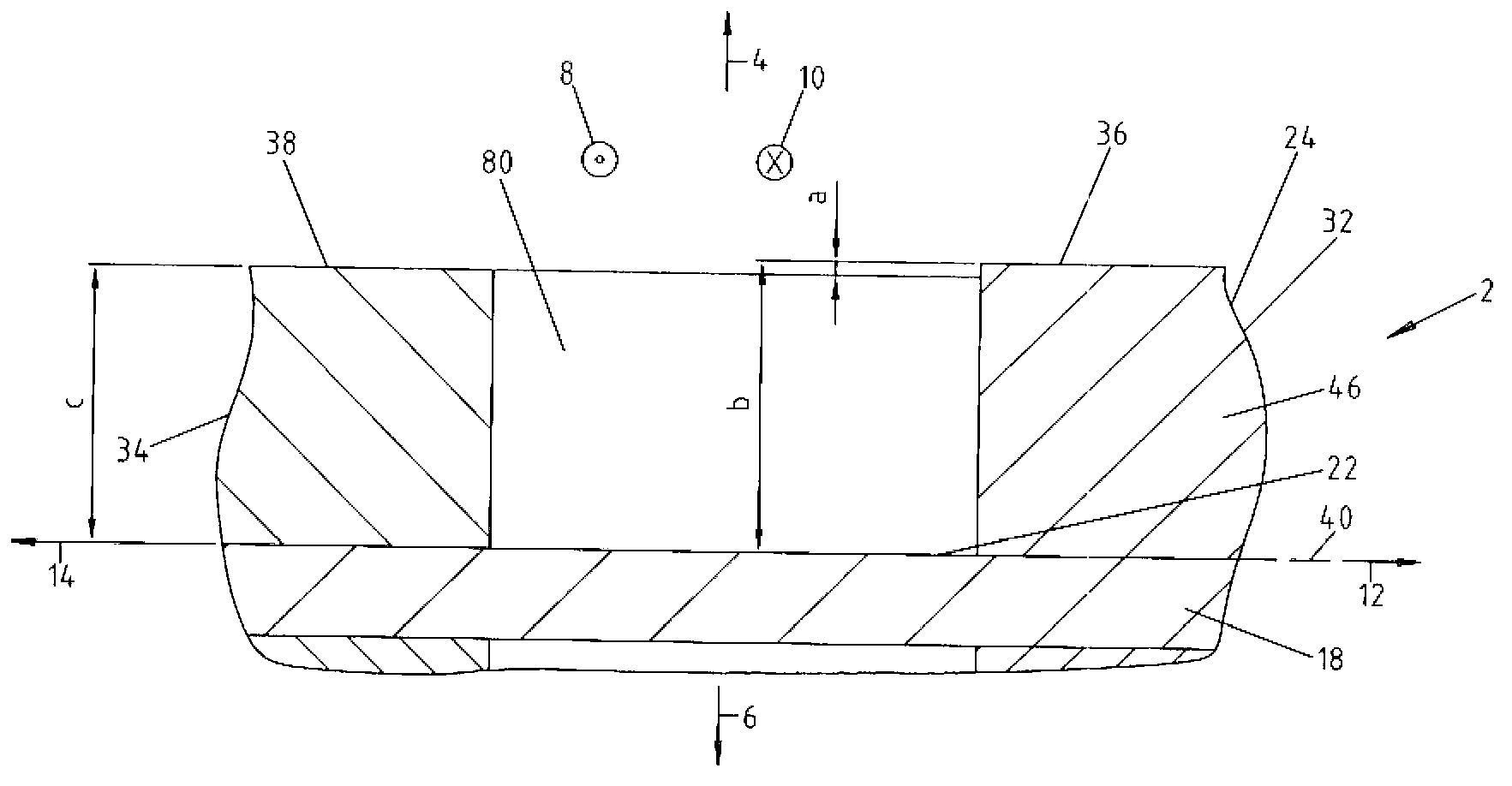

[0033] Figure 1 to Figure 3A first embodiment of a friction lining 2 according to the invention is shown. In the present case, the friction disk 2 takes the form of a friction disk for a wet-running multi-plate clutch or multi-disk brake, which is preferably hydraulically actuatable. A multi-plate clutch is especially preferably a double-plate clutch, in which at least one steel plate is assigned to each of the friction plates 2 , via which friction plates 2 can form a frictional rotational drive connection. If the friction lining 2 is a friction lining 2 equipped with a paper friction lining on one side, it is similarly possible, however, to assign an additional friction lining 2 as a friction partner to each of these friction linings 2. One. exist figure 1 The opposite axial directions 4 , 6 , the opposite radial directions 8 , 10 and the opposite circumferential directions 12 , 14 of the friction lining 2 in the form of an annular disk are indicated by corresponding arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com