Touching screen

A touch screen and lead-out electrode technology, applied in printed circuit, instrument, electrical digital data processing, etc., can solve the problems of time-consuming inspection, time-consuming and labor-intensive, difficult judgment, etc., and achieve easy production, reliable electrical contact and contact separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

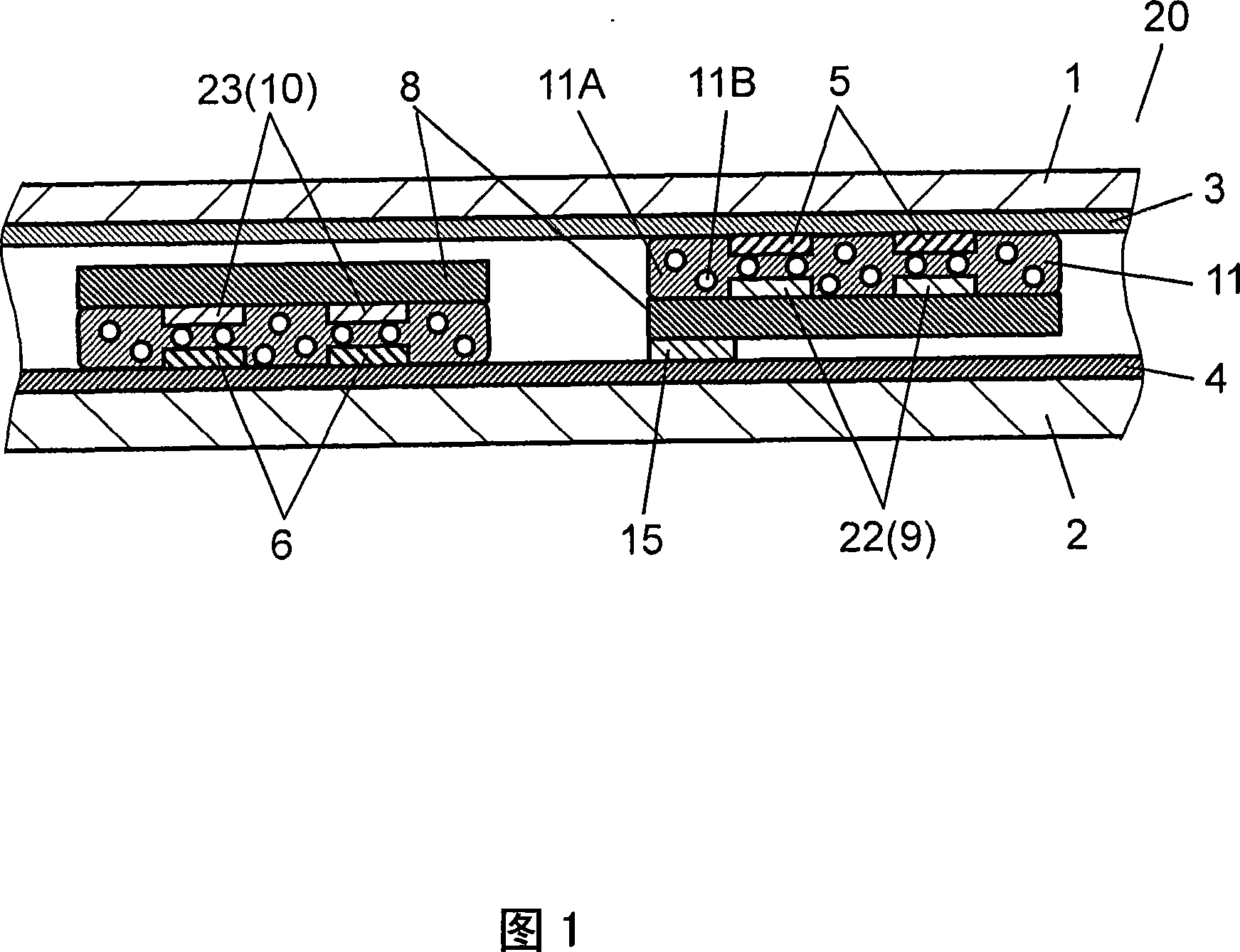

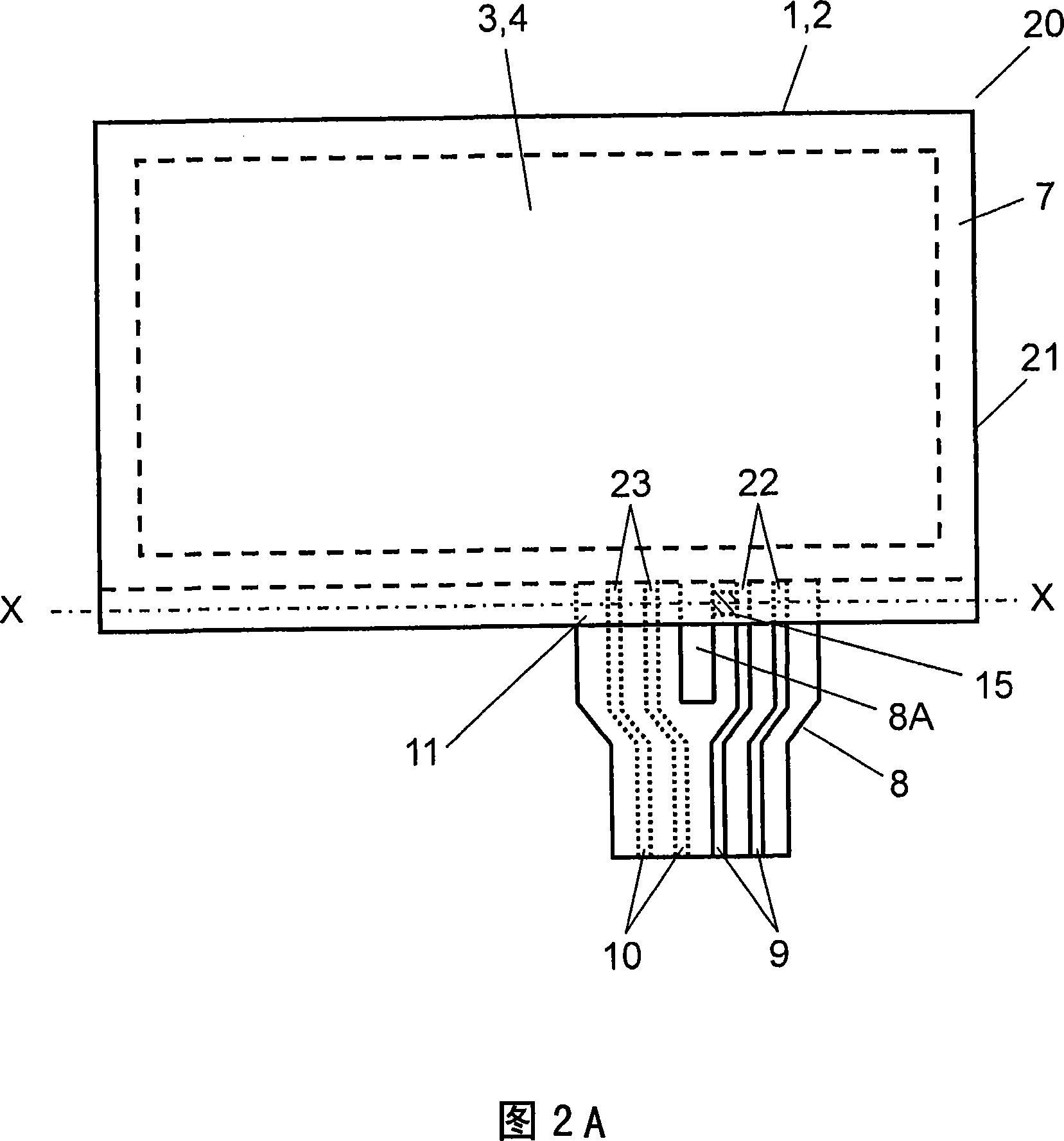

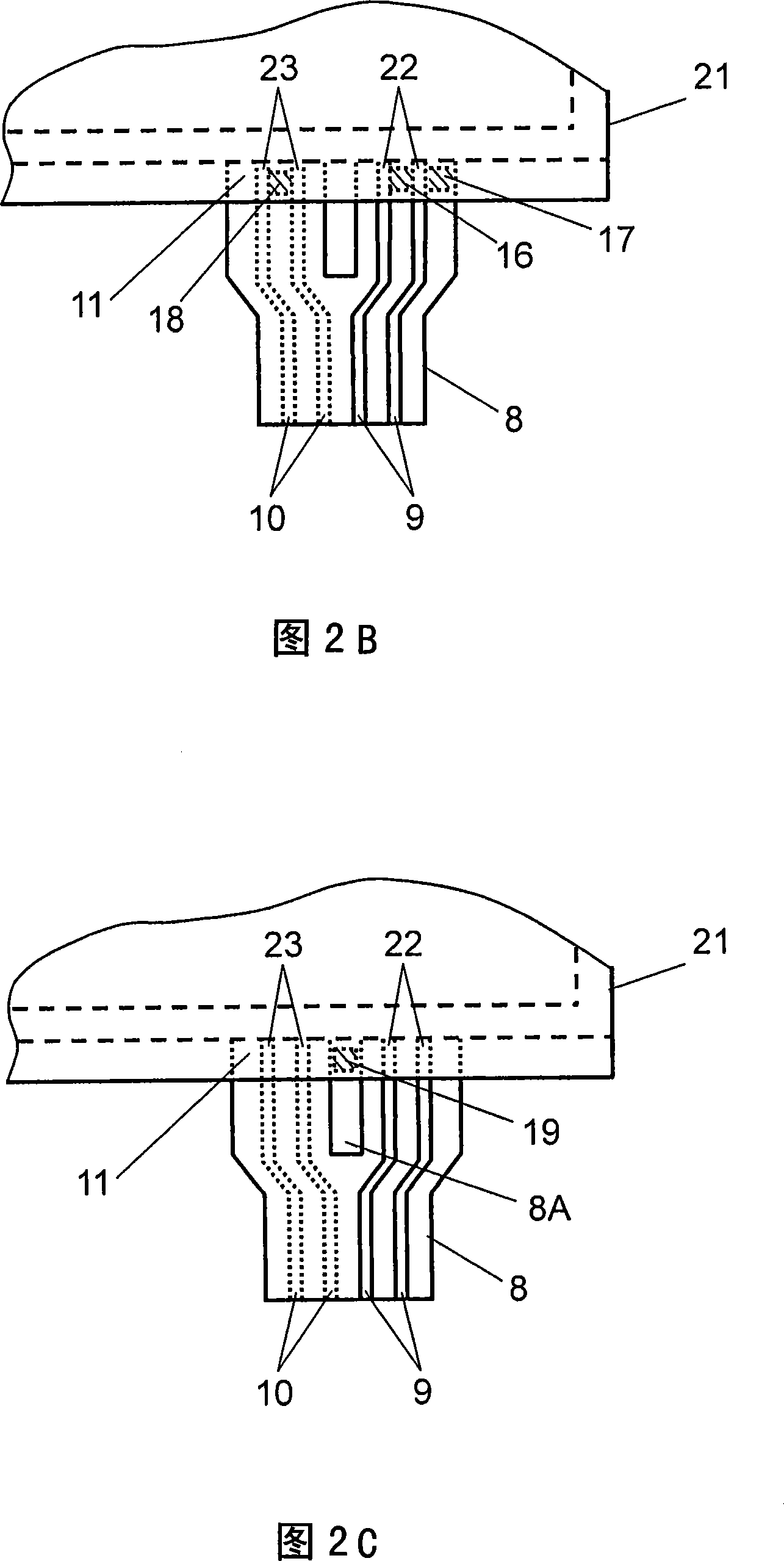

[0030] 1 and 2A are diagrams illustrating a touch panel according to an embodiment of the present invention. Among them, FIG. 1 shows a cross-sectional view taken along line X-X in FIG. 2A.

[0031] The touch panel 20 of this embodiment has a panel portion 21 and a wiring board 8 . The panel unit 21 has a light-transmitting upper substrate 1 in the form of a film such as polyethylene terephthalate or polycarbonate, and a light-transmitting lower substrate 2 such as glass, acrylic resin, or polycarbonate. A translucent upper conductive layer 3 such as indium tin oxide or tin oxide is formed on the lower surface of the upper substrate 1 , and a lower conductive layer 4 made of the same material is formed on the upper surface of the lower substrate 2 . As a method for producing the upper and lower conductive layers 3 and 4, for example, a thin film forming method such as sputtering or vacuum deposition can be used.

[0032] On the upper surface of the lower conductive layer 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com