Light emitter

A luminous body and polarized light technology, applied in the field of luminous body, can solve the problems of unreasonable light irradiation range, large loss of light energy, glare and other problems of luminous body, and achieve the effect of improving light energy utilization rate and large luminous angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

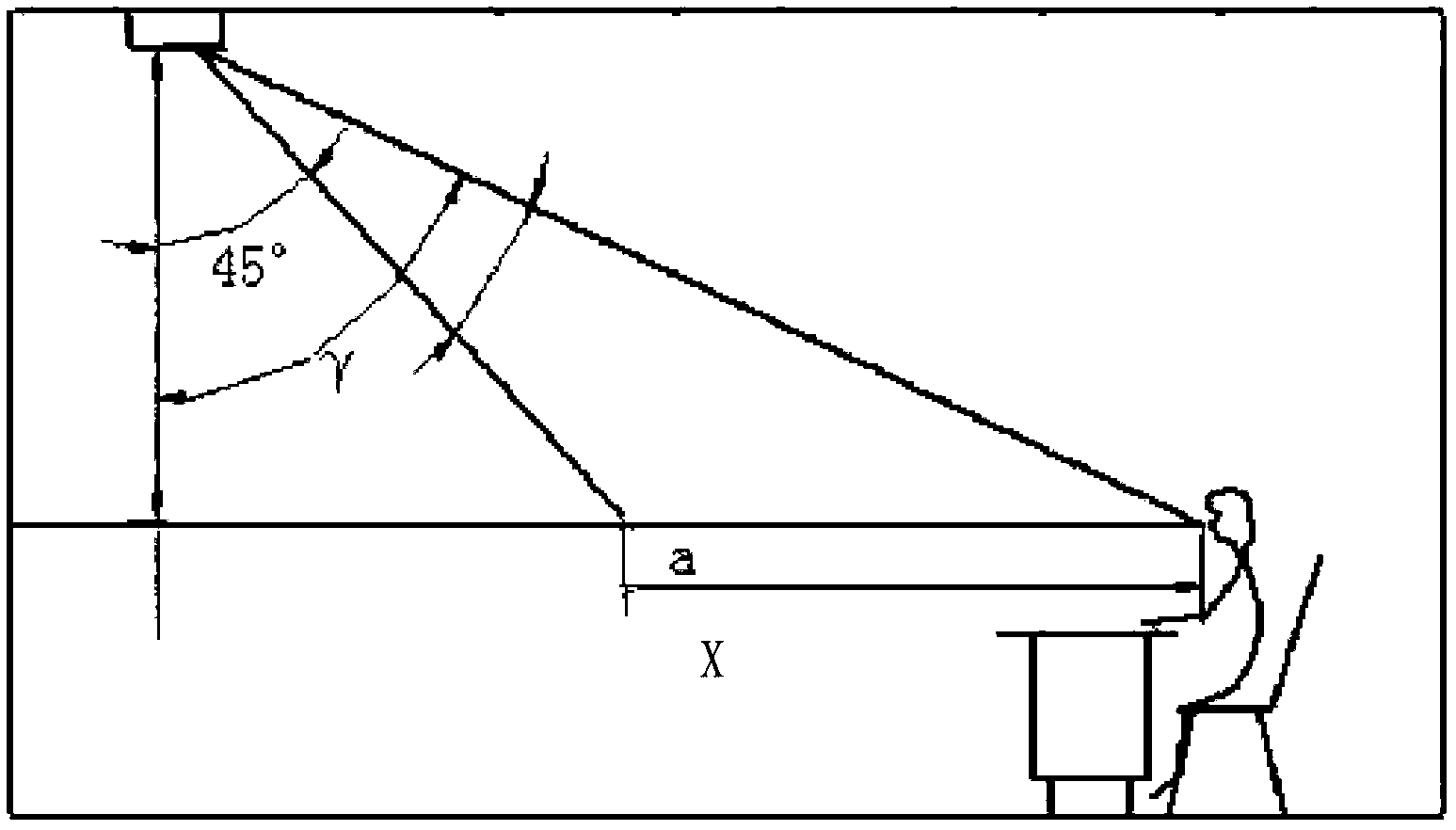

[0036] In this technical solution, the illuminant adopts polarized straw hat lamp beads, and the polarized straw hat lamp beads are arranged on the outer periphery of the carrier in the same way, and the straw hat lamp beads include a bracket 1, an internal reflector 2, and a package lens 3 and LED chips4.

[0037] Further, in order to make the polarized light of the illuminant downward, reduce the waste of light sources, and reduce the glare angle, refer to Figure 7 The specific structure of the straw hat lamp beads used in this technical solution is as follows:

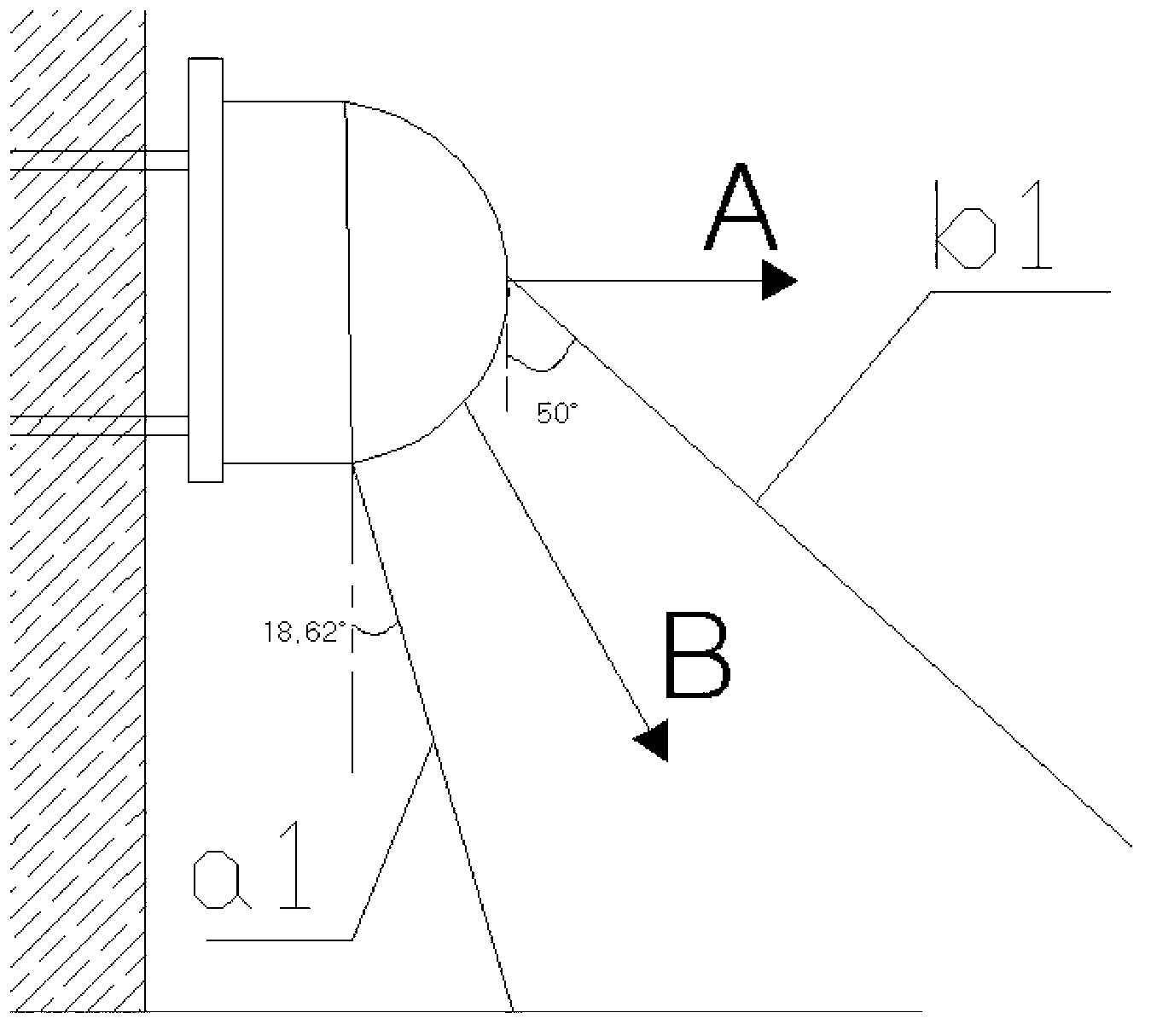

[0038] The internal reflector 2 is a "bowl-shaped" internal reflector 2, the opening diameter of which is larger than the diameter of the bottom, the LED chip 4 is placed at the bottom of the internal reflector 2, and the internal reflector 2 is inclined at a certain angle. On the bracket 1; the packaging lens encapsulates the internal reflector 2 and the LED chip 4; the packaging lens 3 is a C90°-270° asymmetric ...

Embodiment 2

[0044] refer to Figure 9 , different from the above technical solution, the curved surface of the encapsulating lens 3 is asymmetrical at C90°-270°. If the bottom surface of the internal reflector is not inclined, the incident ray 5 will be refracted on the lens surface, instead of being emitted in the direction of the original incident ray 6 , it will become the direction of the refracted ray 7 . The lamp beads of this structure only rely on the asymmetric shape of the lens to change the direction of light emission.

Embodiment 3

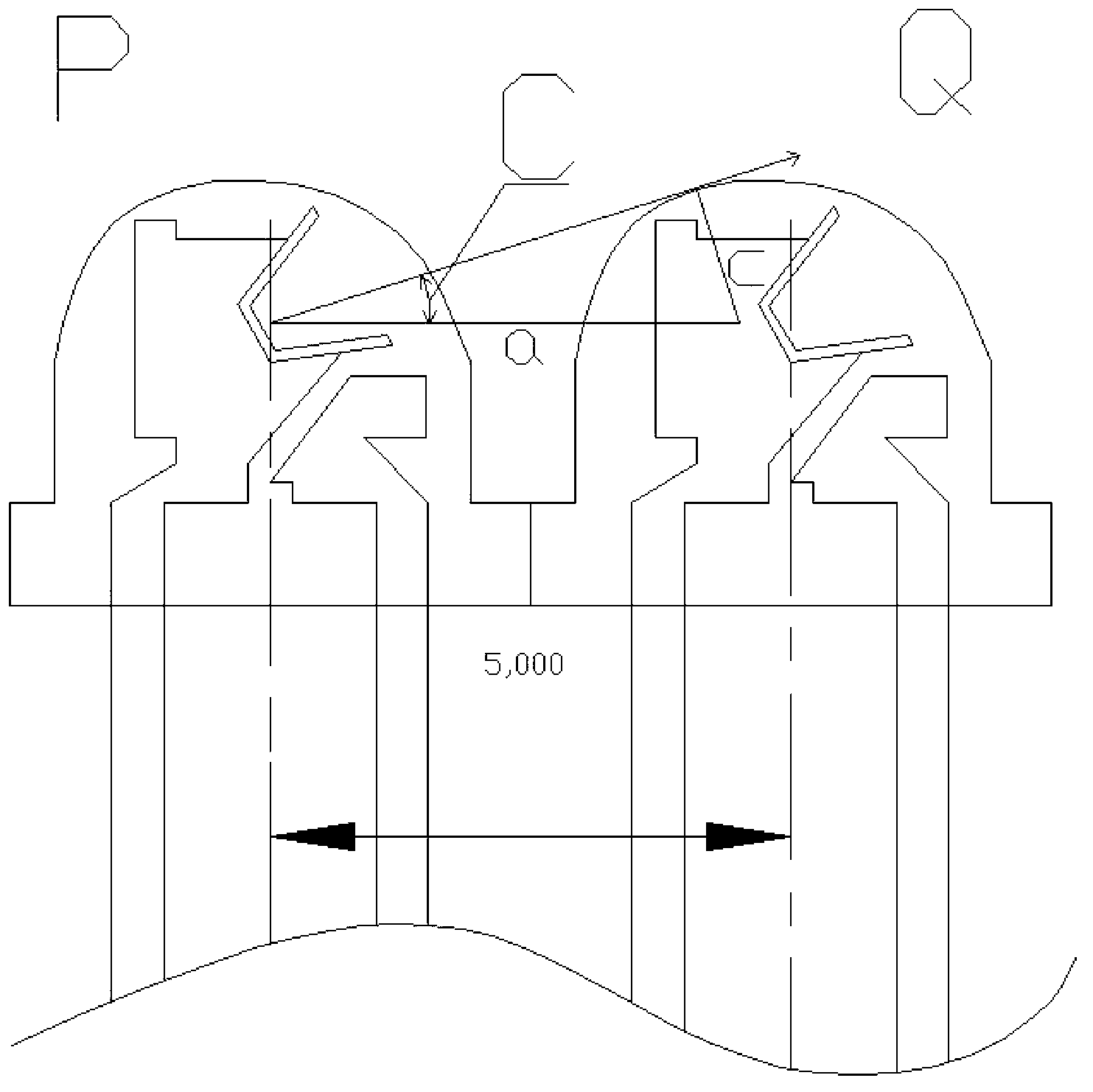

[0046] refer to Figure 10 Different from the above technical solution, the bottom surface of the LED chip is inclined, and the direction of the inclination is uncertain. The curved surface of the packaging lens 3 is symmetrical to the central axis of the lamp bead. This structure of the LED lamp bead can rely on the LED chip and the package placed obliquely. The cooperation of the lens 3 obliquely deflects the final light emitting direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com