Method for electrically simulating mechanical inertia

A technology of mechanical inertia and electrical simulation, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of inertia adjustment difficulty, low degree of automation, and simulation level difference, so as to improve the accuracy of inertia simulation, improve the degree of automation, and simplify the mechanical structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

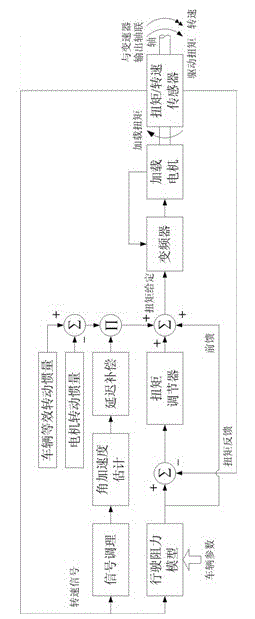

[0018] see figure 1 , the present invention provides a kind of method of electric simulation mechanical inertia, comprises steps as:

[0019] (1) Fix the transmission to be tested on the transmission test bench, start the control computer and the frequency converter, and input the parameters of the vehicle that matches the transmission to be tested into the control computer;

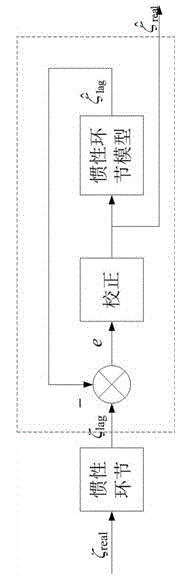

[0020] (2) The control computer detects the speed of the output shaft of the transmission, and calculates the torque to be loaded and the inertia to be simulated by the loading motor in the transmission test bench according to the parameters of the vehicle. The calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com