Self-learning synchronous corrosion control system and method

A control system, self-learning technology, used in general control systems, control/regulation systems, adaptive control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

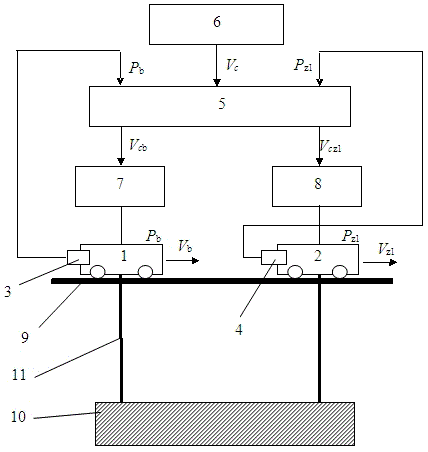

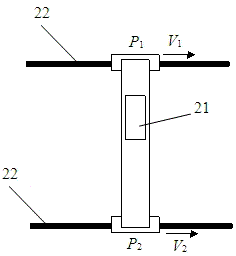

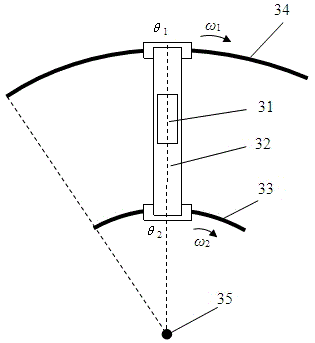

[0027] Taking the synchronous deviation correction control system of a crane as an example to illustrate the self-learning synchronous deviation correction control system of the present invention. The self-learning synchronous deviation correction control system includes an operation control device, the operation control device is connected with a synchronous deviation correction controller, and the synchronous deviation correction controller is connected with at least two drive units, and each drive unit is connected to the corresponding driven equipment respectively. The driven equipment is respectively provided with position detectors, and the signal output terminals of the position detectors are connected to the synchronous deviation correction controller. The position information of the drive equipment sends synchronous running speed commands to each drive unit. The drive unit is a benchmark drive unit and m driven drive units, where m≥1 is a positive integer. The drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com