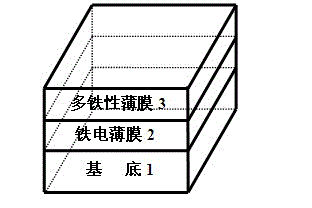

Low-leakage-current semiconductor film heterojunction and preparation method thereof

A leakage current and semiconductor technology, applied in the field of new semiconductor composite materials, can solve problems that hinder the application of ferroelectric-ferromagnetic composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

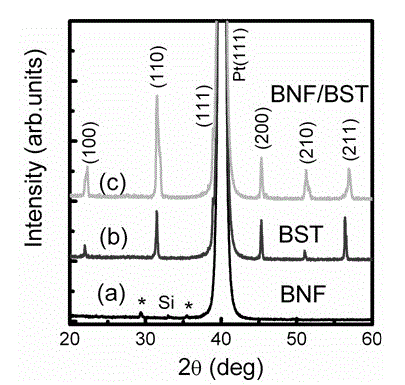

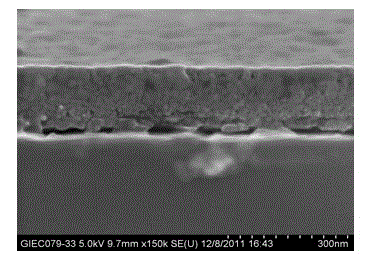

Embodiment 1

[0030] Barium-rich barium strontium titanate (Ba 1-x Sr x )TiO 3 (BST, x =0.35) target, Nd-doped Nd-bismuth ferrite (Bi 0.875 Nd 0.125 )FeO 3 For the target, the two targets were annealed at 1350°C and 850°C respectively. On the substrate Pt / Ti / SiO by radio frequency magnetron sputtering 2 / Si deposition (Ba 0.65 Sr 0.35 ) TiO 3 Thin film, the film thickness is less than 200 nm, deposition environment: the substrate temperature is maintained at about 550oС, the atmosphere maintains the oxygen / argon molar ratio of 4:1, the vacuum degree is at 1.5Pa, and then in (Ba 0.65 Sr 0.35 )TiO 3 Neodymium bismuth ferrite (Bi 0.875 Nd 0.125 )FeO 3 (BNF) film, substrate temperature and vacuum conditions are the same as barium strontium titanate (Ba 0.65 Sr 0.35 ) TiO 3 The film preparation conditions are the same. Rapid annealing of the deposited film in a nitrogen atmosphere, the annealing process must consider the lattice matching of the substrate, and select an appropr...

Embodiment 2

[0032] Sr-rich barium strontium titanate (Ba 1-x Sr x )TiO 3 (BST, x =0.75) target, Nd-doped Nd-bismuth ferrite (Bi 0.875 Nd 0.125 )FeO 3 For the target, the two targets were annealed at 1350°C and 850°C respectively. On the substrate Pt / Ti / SiO by radio frequency magnetron sputtering 2 / Si deposition (Ba 0.25 Sr 0.75 )TiO 3 The film, film thickness, deposition environment, substrate temperature and atmosphere are the same as in Example 1. The obtained heterojunction film has a leakage current density of 10 under an electric field of 300 kV / cm -4 A / cm 2 , compared with the doped iron neodymium bismuth (Bi 0.875 Nd 0.125 )FeO 3 The leakage current density of the film is three orders of magnitude lower.

Embodiment 3

[0034] Preparation of barium zirconate titanate Ba(Zr y Ti 1-y )O 3 (BZT, y =0.20) target, Nd-doped Nd-bismuth ferrite (Bi 0.875 Nd 0.125 )FeO 3 For the target, the two targets were annealed at 1350°C and 850°C respectively. On the substrate Pt / Ti / SiO by radio frequency magnetron sputtering 2 Deposition of Ba(Zr on / Si0.20 Ti 0.80 )O 3 The film, film thickness, deposition environment, substrate temperature and atmosphere are the same as in Example 1. The obtained heterojunction film has a leakage current density of 10 under an electric field of 300 kV / cm -7 A / cm 2 , compared to the doped Nd-bismuth ferrite (Bi 0.875 Nd 0.125 )FeO 3 The leakage current density of the film is 5 orders of magnitude lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leakage current density | aaaaa | aaaaa |

| Leakage current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com