Outdoor pre-installed transformer substation and installation method thereof

A technology of prefabricated substation and installation method, which is applied in the direction of power distribution substation, switchgear, electrical components, etc. It can solve the problems of difficult installation and maintenance, long production cycle, and easy deformation of the whole, and achieves good heat insulation and waterproof effects. Simple processing, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

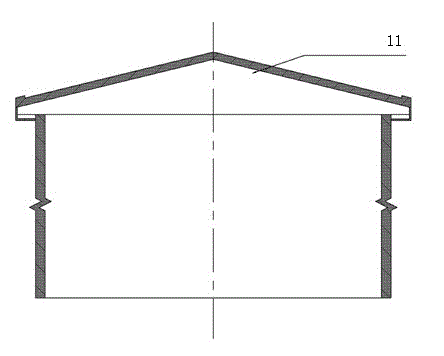

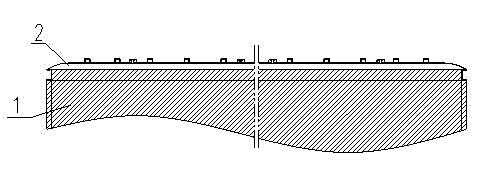

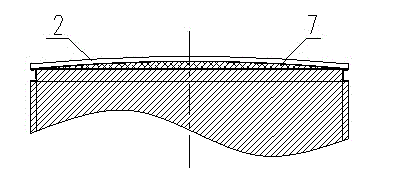

[0077] As the third implementation mode of the outdoor prefabricated substation of the present invention, it is also a simplified implementation mode. The outdoor prefabricated substation includes: a main box body 1 and a top cover 2 . The top cover 2 is fixed on the top of the main box body 1, and the top cover 2 includes one or two first modular arc-shaped sealing units. If the top cover 2 includes two first modular arc-shaped sealing units, the two first modular arc-shaped sealing units are arranged symmetrically along the center. The first modular arc-shaped sealing plate unit includes a modular end sealing plate 3, a modular sealing plate 1 and a modular sealing plate 2 5, and one end of the modular end sealing plate 3 is an inverted “L”-shaped bending structure, Both ends of the modular sealing plate-4 are inverted "L"-shaped bending structures. The two ends of the modular sealing plate 2 5 are bent to form a “convex” structure, and the two ends of the modular sealing ...

specific Embodiment approach

[0080] A specific implementation of an outdoor prefabricated substation installation method, comprising the following steps:

[0081] S101: Make the main box body 1, the modular end seal plate 3 and / or the first modular seal plate 4 and / or the second modular seal plate 5, and install the modular end seal plate 3 and / or the first modular seal plate 4 Laying on the top of the main box 1;

[0082] S102: According to two inverted "L"-shaped bending structures corresponding to a "convex"-shaped structure, the modular sealing plate 2 5 is laid correspondingly, so that the "convex"-shaped structure of the modular sealing plate 2 5 is covered on the modular The outer surface of the end sealing plate 3 and / or the modular sealing plate-4 inverted “L”-shaped bending structure;

[0083] S103: Through the positioning hole between the modular end sealing plate 3 and / or the modular sealing plate 1 4 and the modular sealing plate 2 5, and the positioning hole of the top frame of the main box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com