Central clutch release means

A clutch and separator technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as sensor device failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

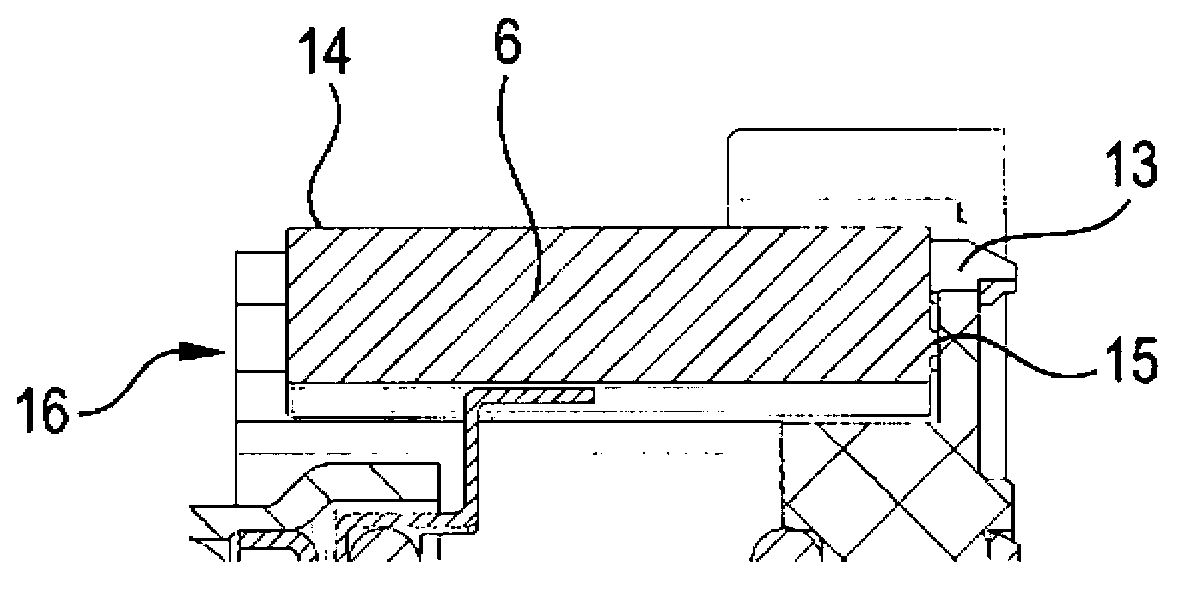

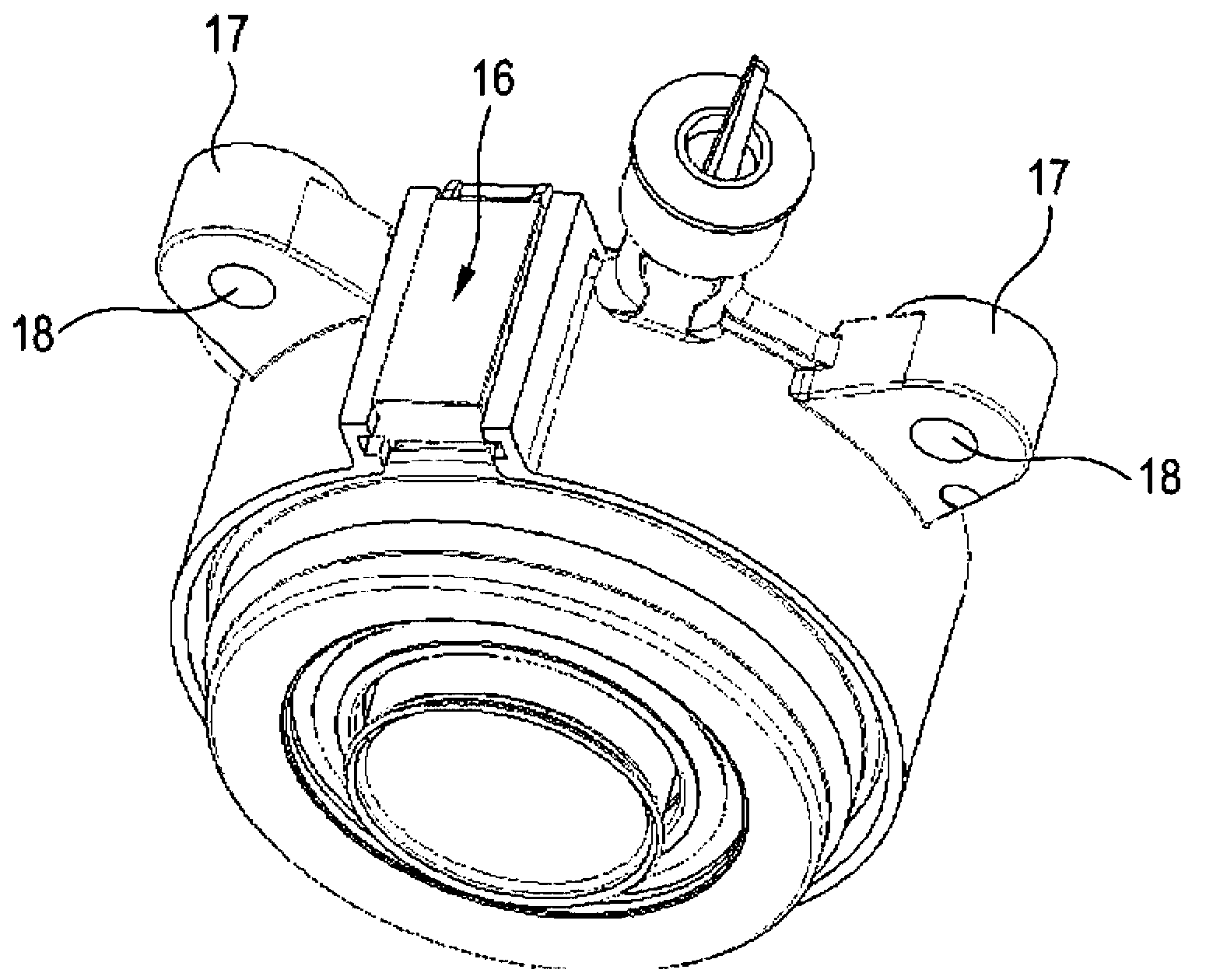

[0027] The drawings are only for the understanding of the invention and are of a schematic nature only. The same elements are denoted by the same reference numerals.

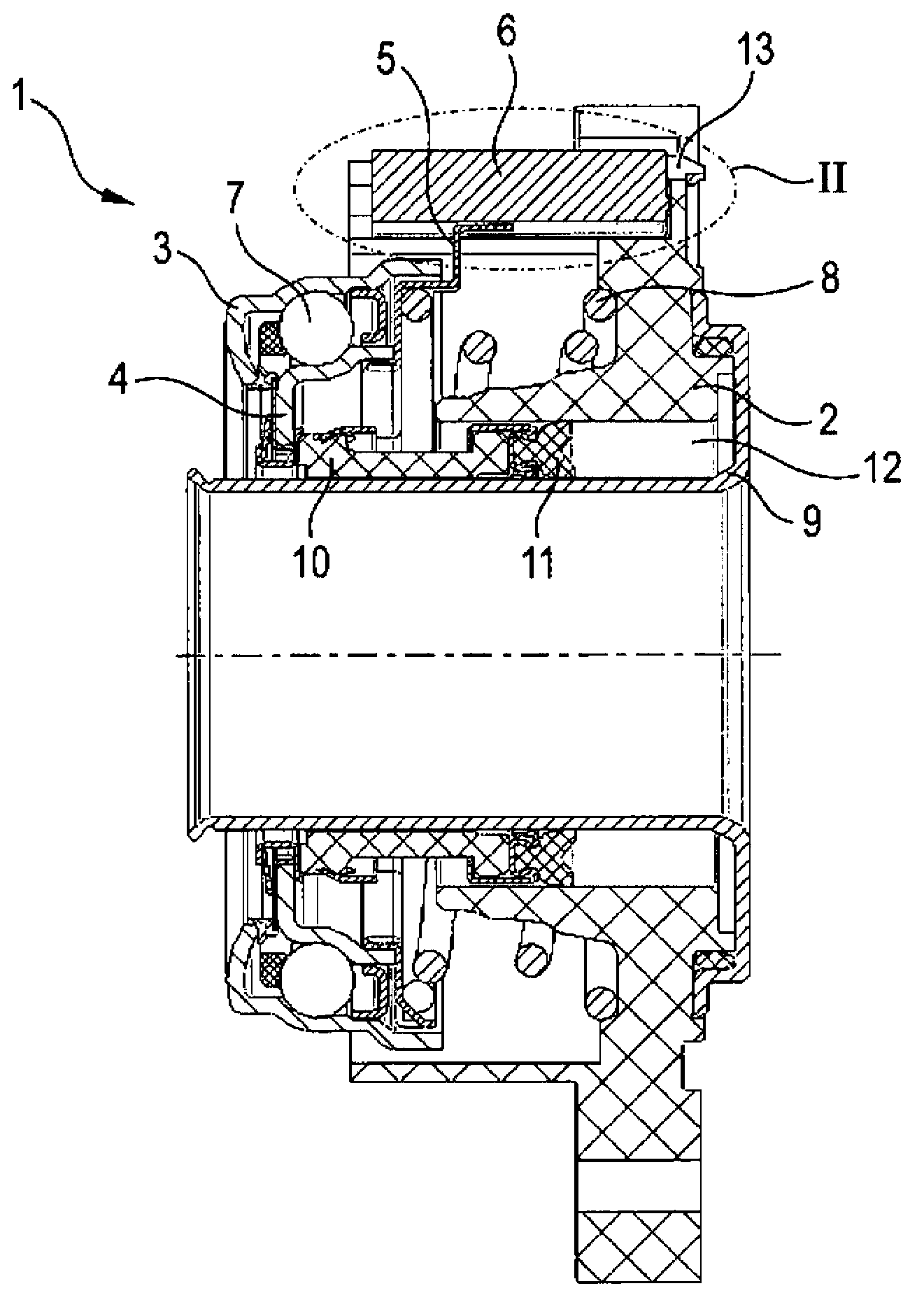

[0028] exist figure 1 A first embodiment of the clutch center release 1 of the invention is shown in . The clutch central separator 1 is also called a central slave cylinder (English: Concentric Slave Cylinder—CSC). The actual housing is provided with the reference numeral 2 . The bearing inner ring 4 of the release bearing connected to the piston 10 is used to actuate the clutch assembly, in particular to make contact with the clutch disc tongues. The bearing outer ring 3 is arranged adjacent to the bearing inner ring 4, which together with the balls located therebetween constitute a release bearing. The position of the preload spring abutment ring 5 and thus of the piston 10 connected to this preload spring abutment ring via the bearing inner ring 4 is sensed by the sensor 6 .

[0029] For the rotation-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com