Device for producing tobacco in the tobacco processing industry and method for operating the device

A technology of processing industry and control device, applied in general control system, adaptive control, control/regulation system, etc., can solve the problems of inoperability of equipment, time-consuming cost, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

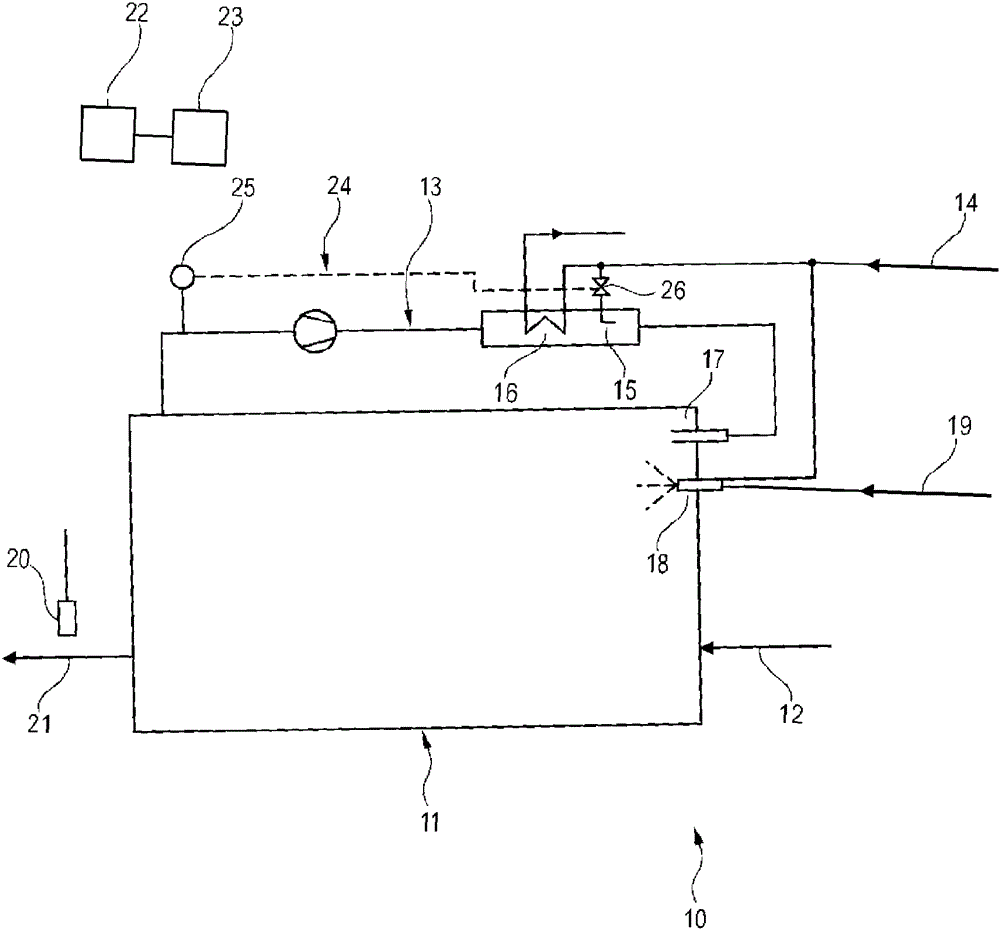

[0013] The device for processing tobacco products comprises a processing device 10 , here a rotating decomposition drum 11 , into which tobacco products 12 , for example from a slicer not shown, are fed (Löse-konditionier trommel) middle. Arranged in the disintegrating drum 11 are devices, not shown, which separate the compressed tobacco leaves as the drum 11 rotates.

[0014] The dissolution properties are positively influenced by increasing the temperature of the tobacco. The introduction of heat into the drum 11 is achieved by means of a process gas impregnated with steam, through which the process gas is guided to the circulation air channel 13 and to the supply nozzles 17 arranged at the tobacco inlet. Steam is introduced from the steam supply line 14 into the circulation air channel 13 by means of nozzles 15 . The process gas temperature can be regulated via a control circuit 24 based on a valve 26 in the steam supply line 14 , which is controlled by means of a signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com