Method for configuring alternative and dynamic drive of Z-direction main shafts of numerically-controlled machine tool with multiple Z-direction shafts and system thereof

A technology for CNC machine tools and spindles, which is applied in automatic control devices, feeding devices, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

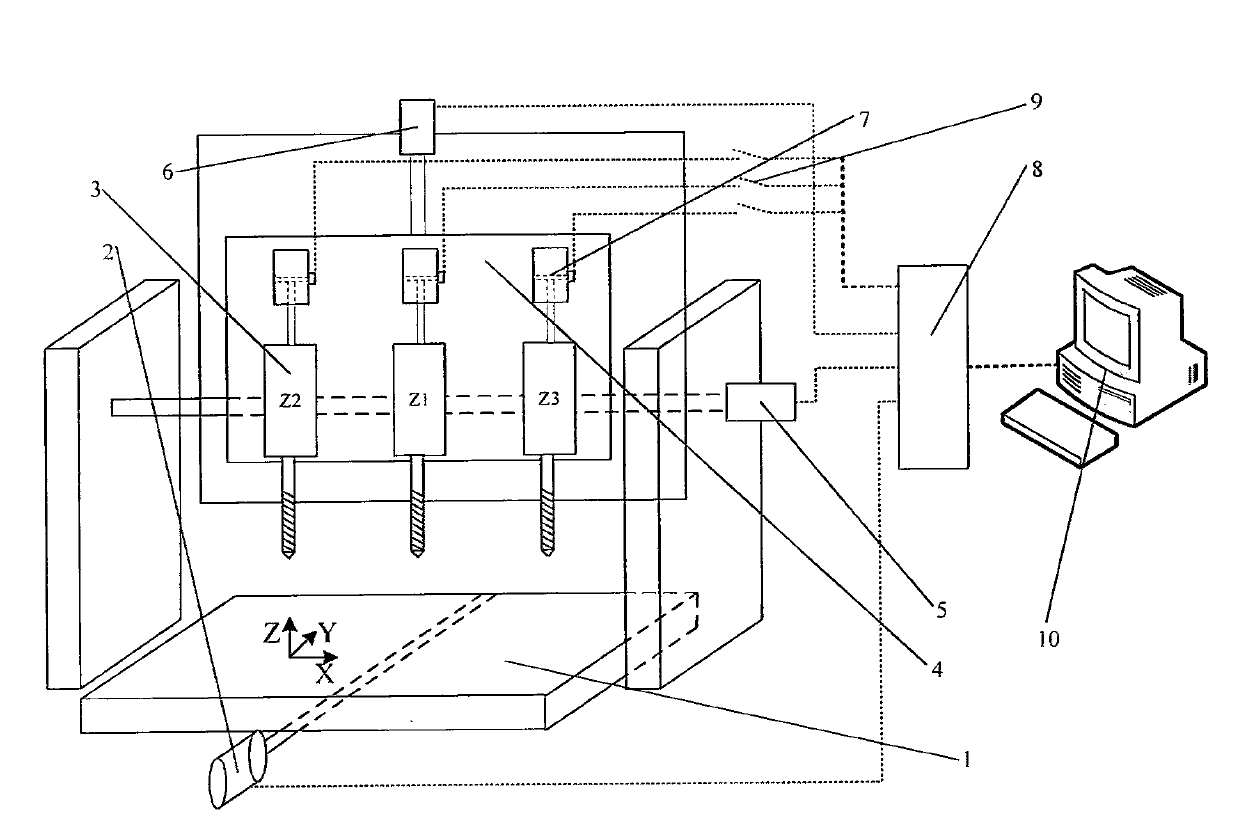

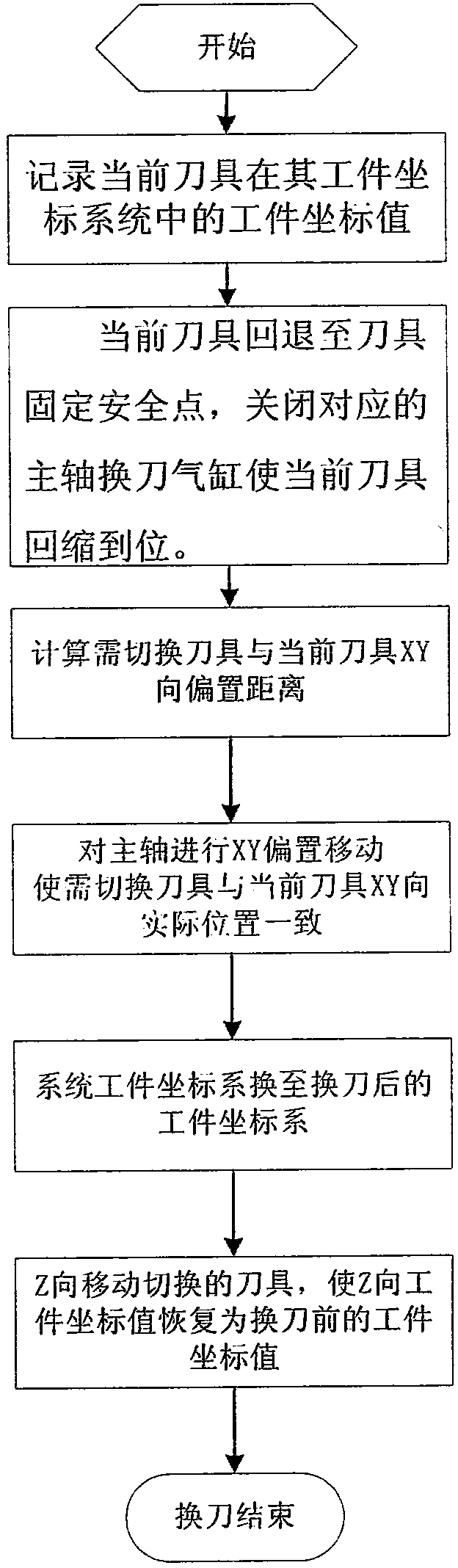

[0017] like figure 1 As shown, a Z-direction spindle wheel drive configuration method of a multi-Z-axis CNC machine tool, the steps of the method are as follows:

[0018] 1) Taking one of the Z-direction spindles 3 as the reference axis, measure the offset distance hX2, hX3...hXn of the tool tip relative to the reference axis in the X direction on the other Z-direction spindle 3 and the offset distance relative to the reference axis in the Y direction hY2, hY3...hYn;

[0019] 2) Carry out the mechanical zero return operation, and the mechanical coordinates are automatically set to zero;

[0020] 3) Set the tool fixing safety point, and drive the tool change cylinder 7 of each spindle through the multi-axis CNC control card 8 to control the Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com