Derusting device

A technology of derusting wheel and jacking device, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., and can solve the problems that derusting machinery is difficult to apply, bowl-type horizontal rod derusting, and complex structure, etc., to achieve High rust removal efficiency, easy operation and good rust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The content of the present invention will be described below in conjunction with specific embodiments.

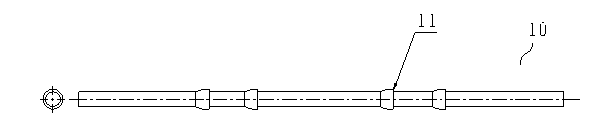

[0035] Such as figure 1 Shown is a schematic diagram of the structure of the bowl-type horizontal pole of the present invention. The bowl-type horizontal pole 10 is a hollow structure, and several buckle bowls 11 are arranged on its outer surface, and the buckle bowls 11 are used together with fasteners to build a firm scaffold.

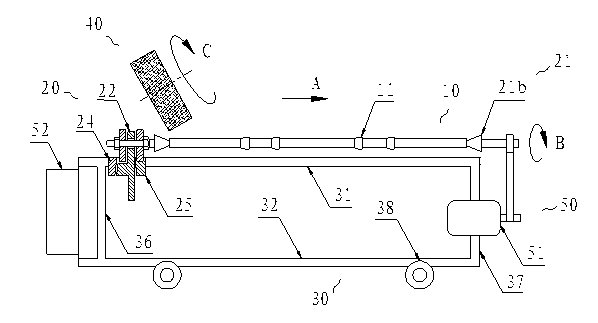

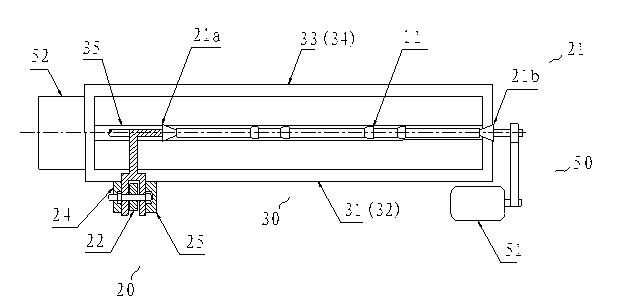

[0036] Such as figure 2 Shown is the front view of the derusting device of the present invention, image 3 Shown is the top view of the derusting device of the present invention. For further elaborating each detail of the derusting device of the present invention, image 3 The descaling wheel is not shown. The derusting device of the present invention includes a tightening device 20 , a body 30 , a derusting wheel 40 , and a transmission control device 50 . The tightening device 20 , the derusting wheel 40 and the transmission contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com