Assembling method for backswing starting mechanism of motorcycle

A technology of recoil starting and assembling method, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems that the torsion spring 4 is easy to rebound and hurt people, it is difficult to maintain balance, and it is difficult to apply force, so as to save labor in installation and improve production. Efficiency and security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

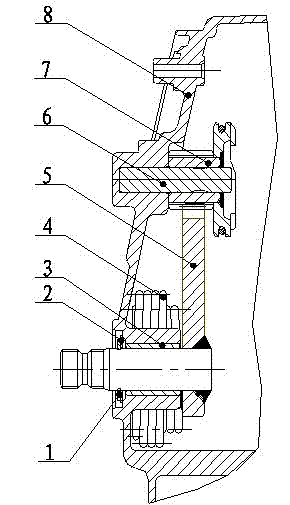

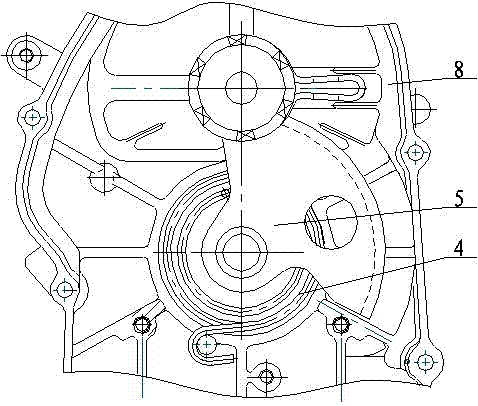

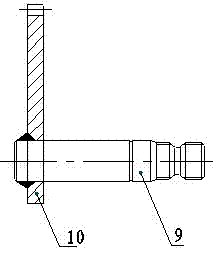

[0025] Attached below figure 1 - attached Figure 9 The functional principles and effects of the present invention will be further described in detail with specific embodiments. Wherein, the structure of the motorcycle recoil mechanism involved in the present invention is the structure of the motorcycle recoil mechanism described in the background technology, which can be found in Figure 1-Figure 6 understand. The assembly aids that the present invention adopts can refer to Figure 7-Figure 8 to understand. When the present invention was implemented, the use status of the assembly aids can be found in Figure 9 to understand.

[0026] In specific implementation, one such as Figure 1-Figure 6 The motorcycle recoil starter mechanism assembly method of the structure shown includes the following steps:

[0027] a. Get as Figure 7-Figure 8 The assembly aid of the structure shown, the assembly aid includes a connecting plate 13, a handle 14 and a connecting rod 16, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com