Structure of truss manipulator

A technology of manipulators and trusses, applied in the field of automated machinery and equipment, can solve the problem of fewer special manipulators, achieve the effects of improving running stability, strengthening rigidity, and reducing running errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

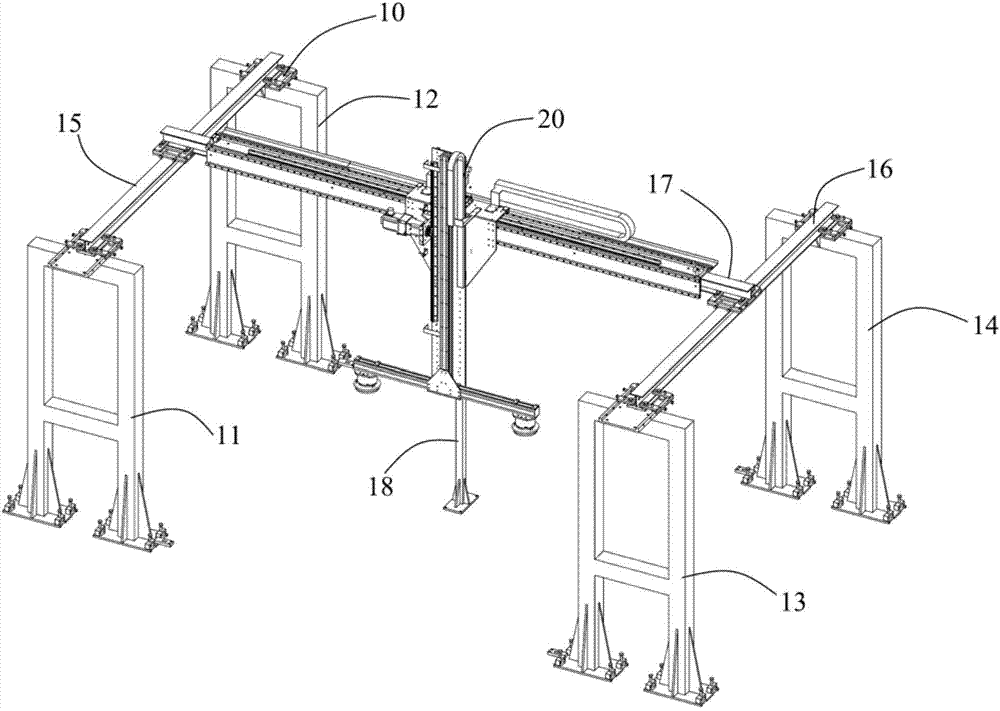

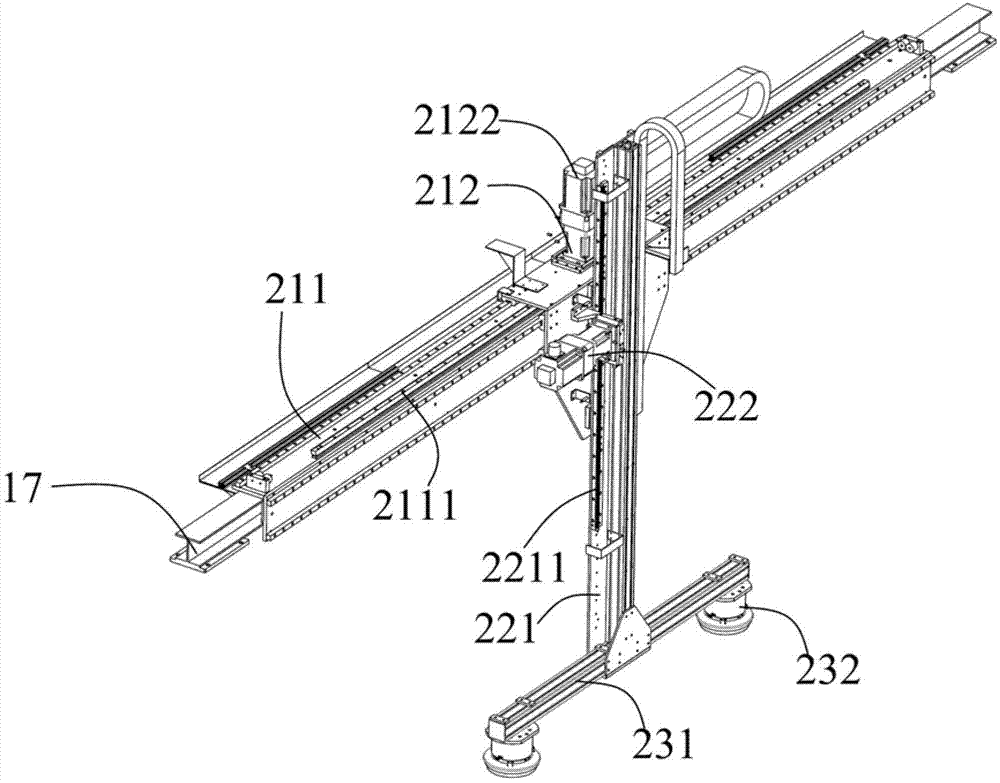

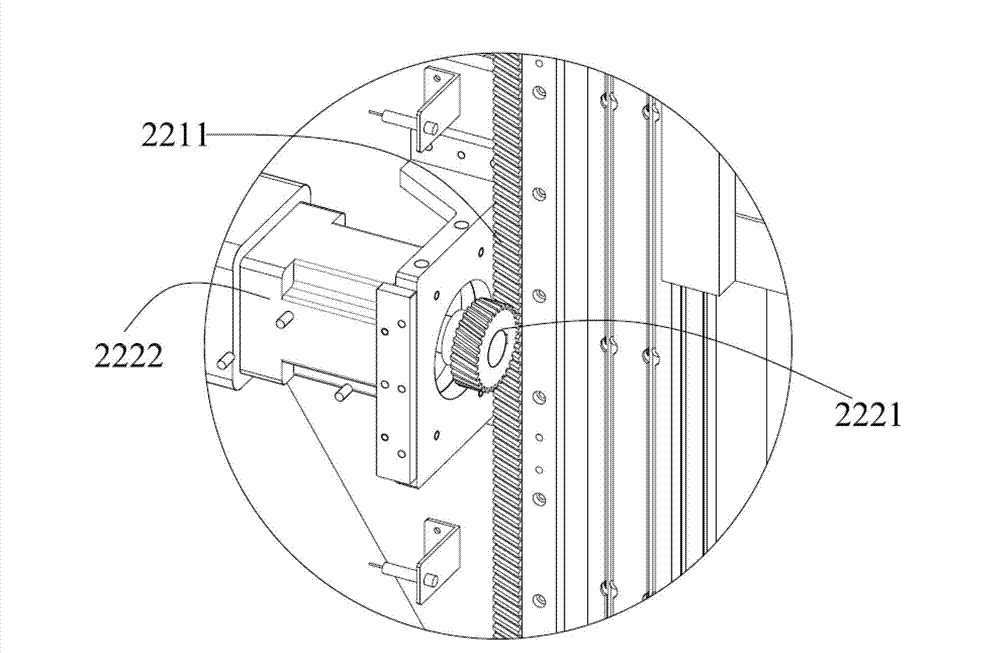

[0035] The invention discloses a truss manipulator structure, which comprises a truss and a manipulator arranged on the truss. The truss includes a plurality of support parts of a gantry structure, and beams for installing the manipulator are arranged on the support parts. The manipulator is a two-degree-of-freedom manipulator. The manipulator includes installation The horizontal movement component on the beam and the vertical movement component vertically installed on the horizontal movement component. The bottom of the vertical movement component is connected with a three-claw gripper. The horizontal movement component and the vertical movement component respectively include a gear and a rack for transmission. The gear and the rack are set as helical teeth meshing with each other.

[0036] Further, the truss includes two sets of supporting groups arranged in parallel, and each supporting group includes two supporting parts and a connecting part connecting the intermediate pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com