Rubber composition used for anti-fire shoes and manufacturing method thereof

A technology of rubber composition and fire-fighting shoes, which is applied in the field of rubber composition to achieve the effect of good performance and enhanced synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

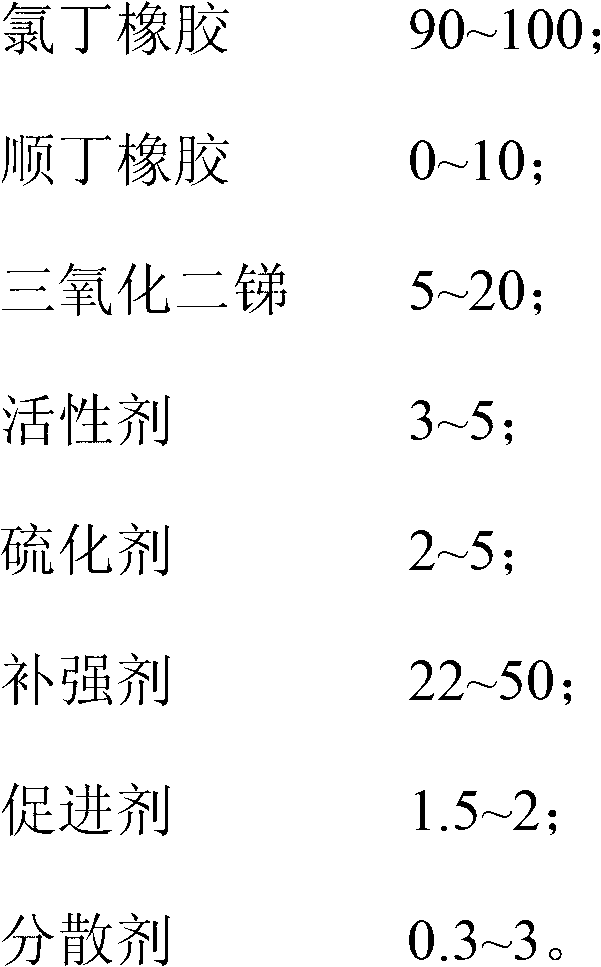

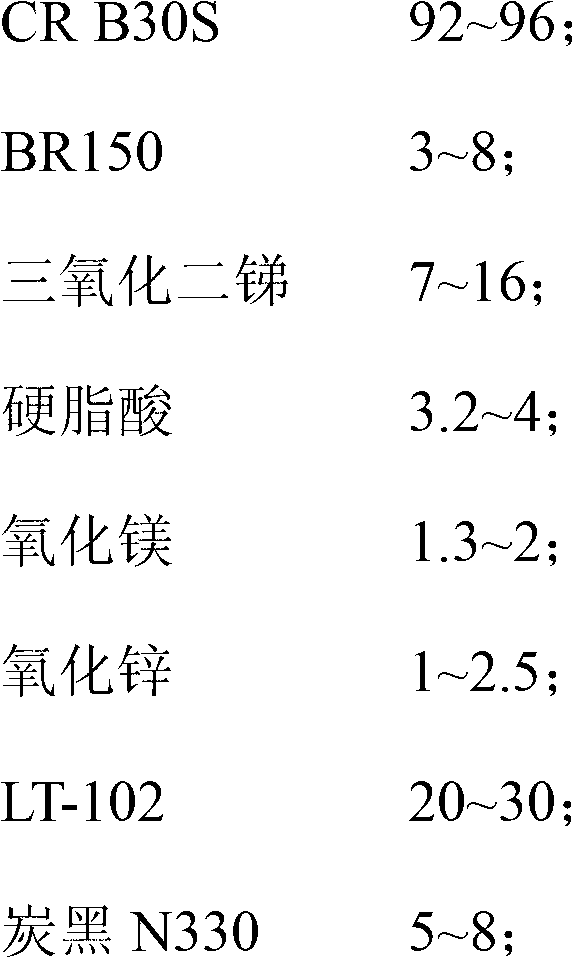

[0097] A rubber composition for fire-fighting shoes, comprising the following components in parts by weight:

[0098] Neoprene 100;

[0100] active agent 3;

[0101] vulcanizing agent 2;

[0102] Reinforcing agent 50;

[0103] Accelerator 2;

[0104] Dispersant 0.3.

Embodiment 2

[0106] A rubber composition for fire-fighting shoes, comprising the following components in parts by weight:

[0107] Neoprene 90;

[0108] Butadiene rubber 10;

[0110] active agent 5;

[0111] Vulcanizing agent 5;

[0112] Reinforcing agent 22;

[0113] Accelerator 1.5;

[0114] Dispersant 3.

Embodiment 3

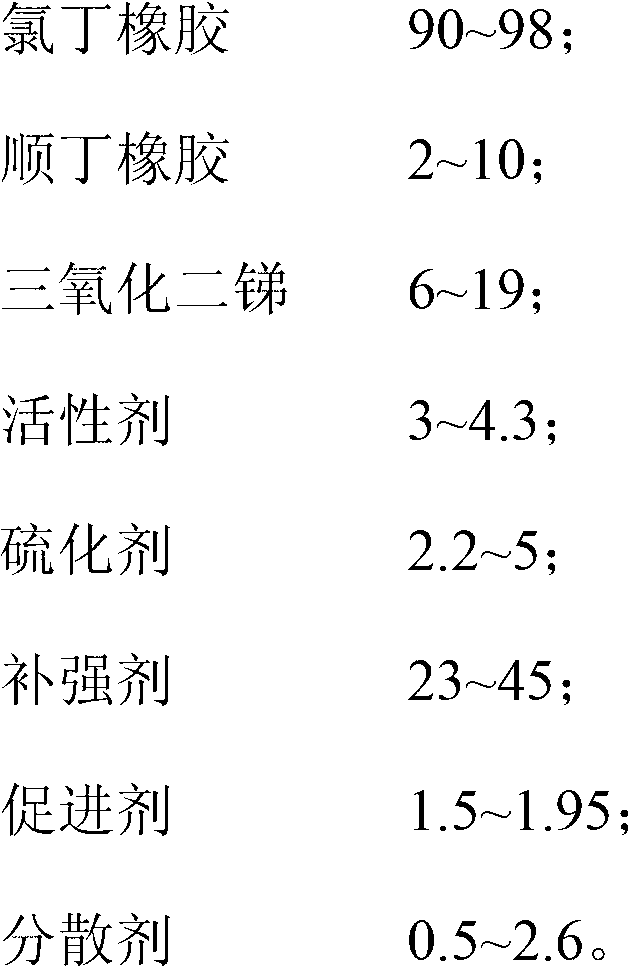

[0116] A rubber composition for fire-fighting shoes, comprising the following components in parts by weight:

[0117] Neoprene 98;

[0118] Butadiene rubber 2;

[0120] active agent 4.3;

[0121] Vulcanizing agent 2.2;

[0122] Reinforcing agent 45;

[0123] Accelerator 1.5;

[0124] Dispersant 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com