Fischer-Tropsch synthesis wax refinement method

A technology of Fischer-Tropsch synthesis wax and refining method, which is applied in the direction of petroleum wax refining, etc., and can solve the problems of polymerization and oxidation reaction, inability to effectively remove crude wax lipids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

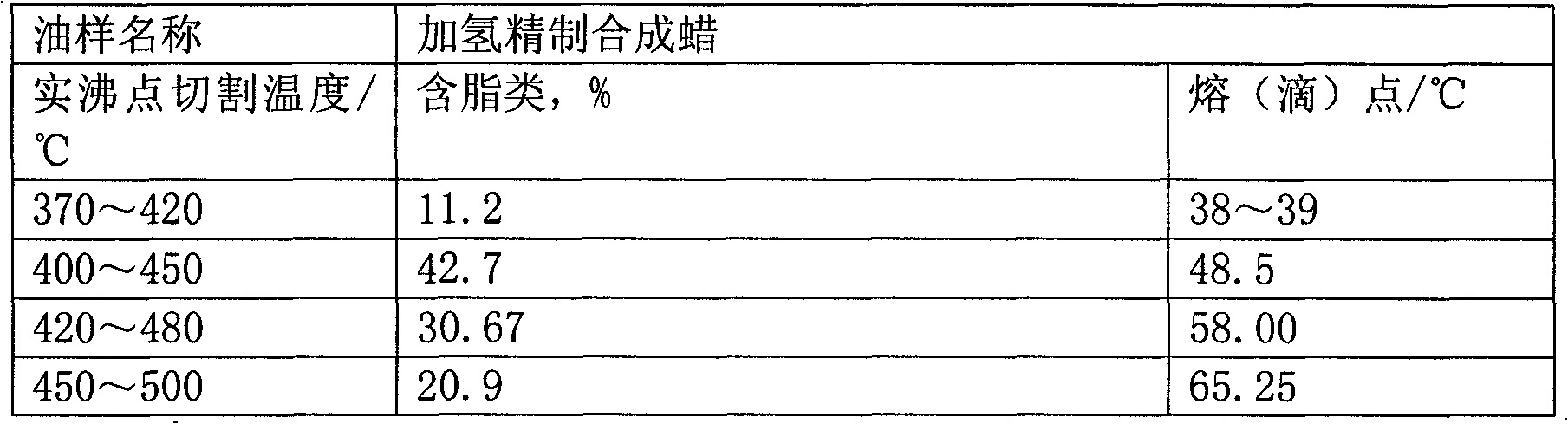

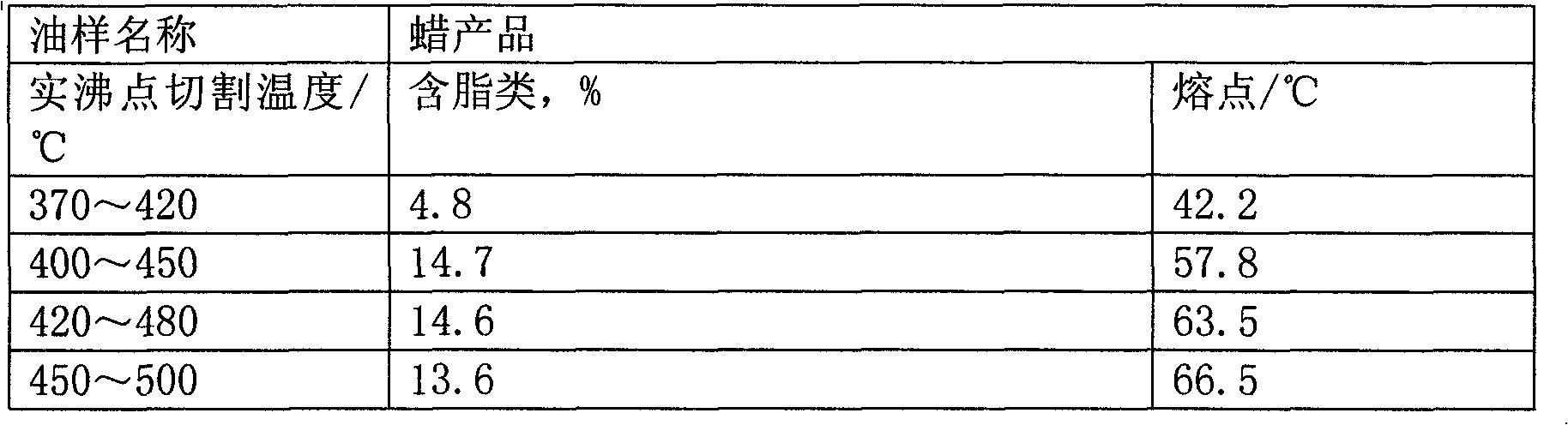

[0016] The method of the invention includes equipment such as a sweat tank, a raw material pump, a circulating water system, and the like. After the crude wax component from the Fischer-Tropsch synthesis system is hydrogenated and refined, the 370-420°C component, 400-450°C component, 420-480°C component and 450-500°C component are firstly transported by the raw material pump to the corresponding sweat tank. Cooling water is passed into the lower part of the sweat tank for cooling, and then heating is carried out after reaching the cooling temperatures of 30-50°C, 35-70°C, 40-80°C and 45-85°C respectively. The operating pressure of the above-mentioned sweat tank is 0.05-0.60Mpa. The lipids and part of the low-melting point wax contained in the wax layer melt and flow into the respective storage tanks by gravity. After the heating and constant temperature is over, the hot water circulation is used to flow the melt in the sweating tank into the finished product tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com